when the right treadle is depressed to start the machine. Also see that

there is a clearance

gap

about

^U*",

or 2.0 mm, wide between the front

edge of the stop

link

and the lobe on the foce of the stop cam

(Fig.

36)

when the machine is in operation.

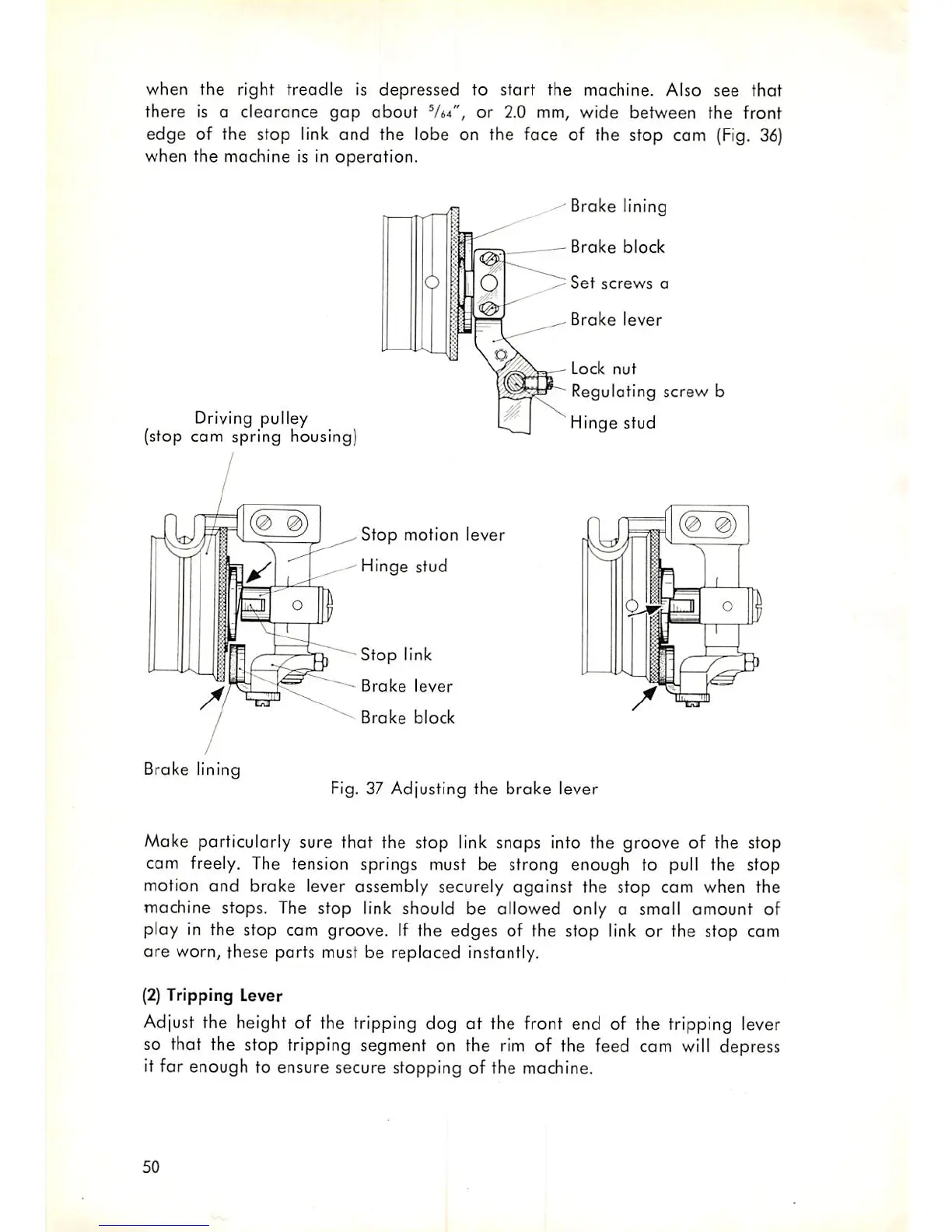

Driving pulley

(stop cam spring housing)

(0 0)

K

(

i

•

Stop

motion lever

Hinge

stud

Stop

link

-

Brake

lever

Brake

block

Brake lining

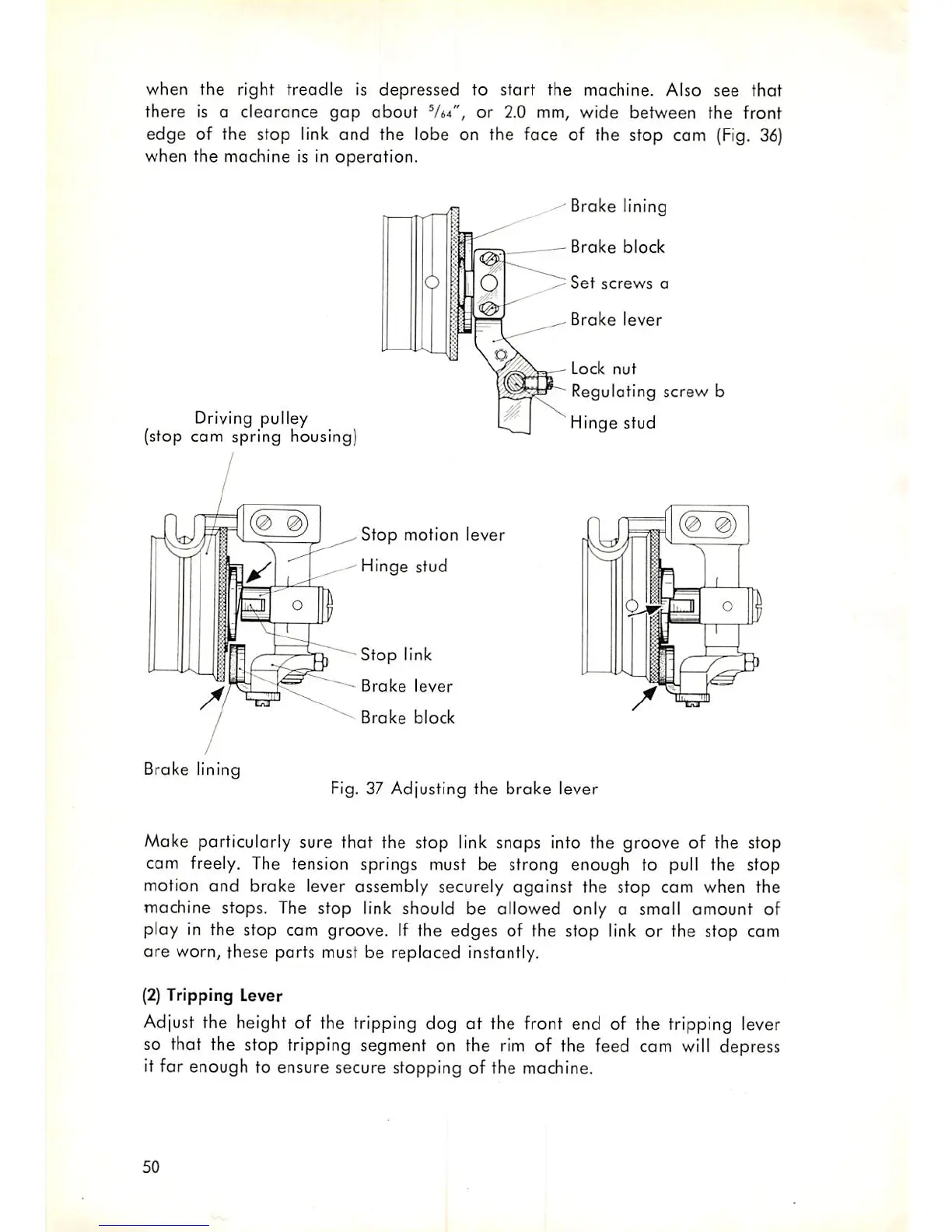

Brake

block

Set

screws

a

Brake

lever

Lock

nut

Regulating

screw

b

Hinge

stud

OJ

Brake lining

Fig. 37 Adjusting the

brake

lever

Make particularly sure that the stop link snaps into the groove of the stop

cam freely. The tension springs must be strong enough to pull the stop

motion

and

brake lever assembly securely

against

the stop cam when the

machine stops. The stop link should be allowed only a small omount of

play in the stop cam groove. If the edges of the stop link or the stop cam

are worn, these ports must be replaced instantly.

(2)

Tripping Lever

Adjust the height of the tripping dog at the front end of the tripping lever

so that the stop tripping segment on the rim of the feed cam will depress

it far enough to ensure secure stopping of the machine.

50

Loading...

Loading...