loosen the nut on the knife pinion stud brocket set screw (Fig. 49), and take

out this screw. Next, remove the knife pinion stud bracket and the knife

assembly.

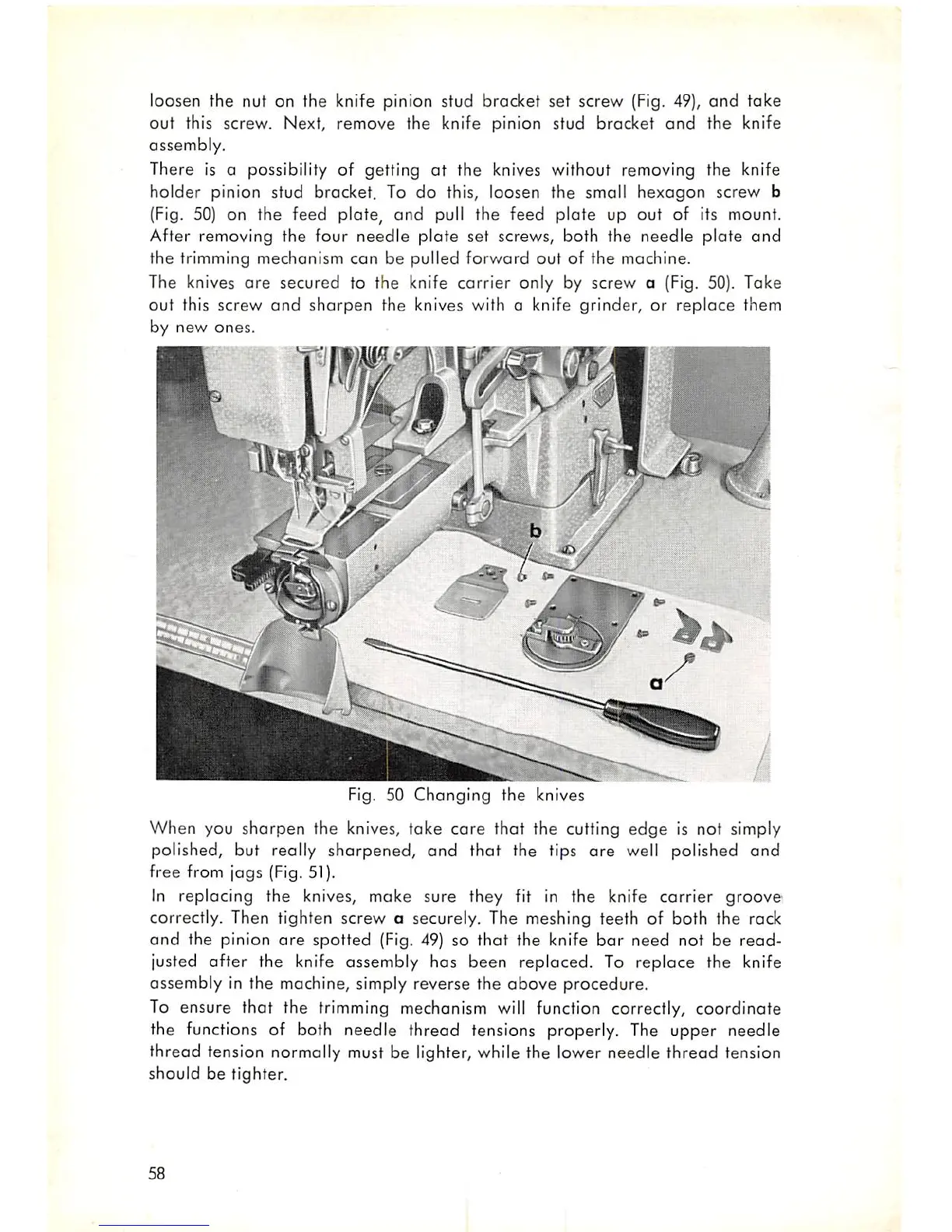

There is a possibility of getting

at

the knives without removing the knife

holder pinion stud bracket. To do this, loosen the small

hexagon

screw b

(Fig. 50) on the feed plate, and pull the feed plate up out of its mount.

After removing the four

needle

plate

set screws, both the

needle

plate

and

the trimming mechanism

can

be pulled

forward

out of the machine.

The knives

are

secured to the knife

carrier

only by screw a (Fig. 50). Take

out

this screw

and

sharpen

the knives with a knife grinder, or

replace

them

by new ones.

Fig. 50

Changing

the

knives

When you sharpen the knives, take

care

that the cutting edge is not simply

polished, but really sharpened, and that the tips

are

well polished

and

free from jags (Fig. 51).

In replacing the knives, make sure they fit in the knife

carrier

groove

correctly. Then tighten screw a securely. The meshing teeth of both the rack

and

the pinion

are

spotted (Fig. 49) so that the knife

bar

need not be read

justed

after

the knife assembly has

been

replaced.

To

replace

the knife

assembly in the machine, simply reverse the

above

procedure.

To ensure that the trimming mechanism will function correctly, coordinate

the functions of both needle thread tensions properly. The upper needle

thread tension normally must be lighter, while the lower needle thread tension

should be tighter.

58

Loading...

Loading...