The electric motor driving the machine should hove a power input of

Va

HP

(0.25

kw)

and

operate

at 1,400 r.p.m. It should be fitted with a

single-groove pulley having o

diameter

of I'Va:", or 50 mm (Order No.

99032).

This pulley develops a sewing speed of

about

1,000 s.p.m.

If, in exceptional cases, a high-speed motor operating at a speed of 2,800

r.p.m. is used, place o two-speed pulley, No.

31326,

between motor and

machine pulleys.

Electrical

information

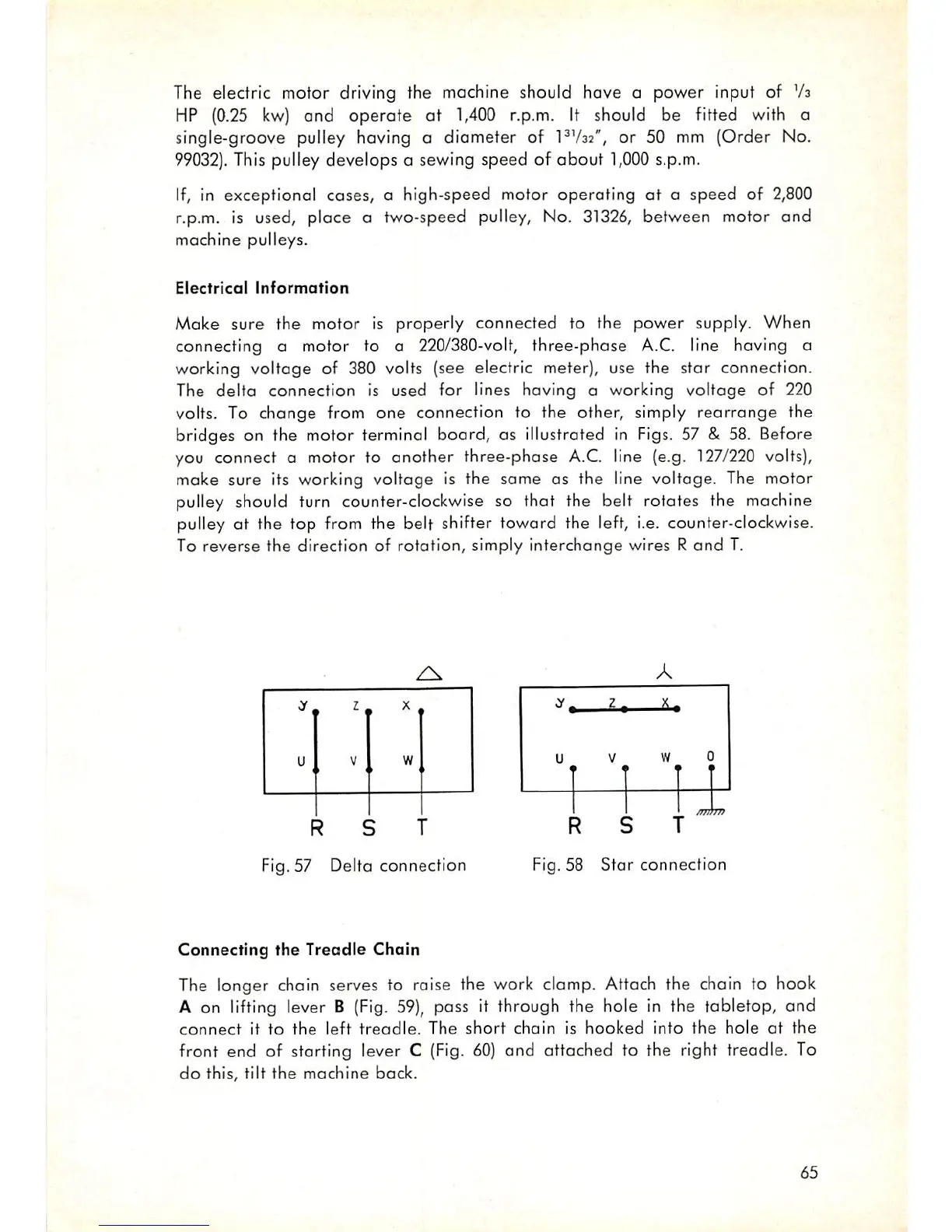

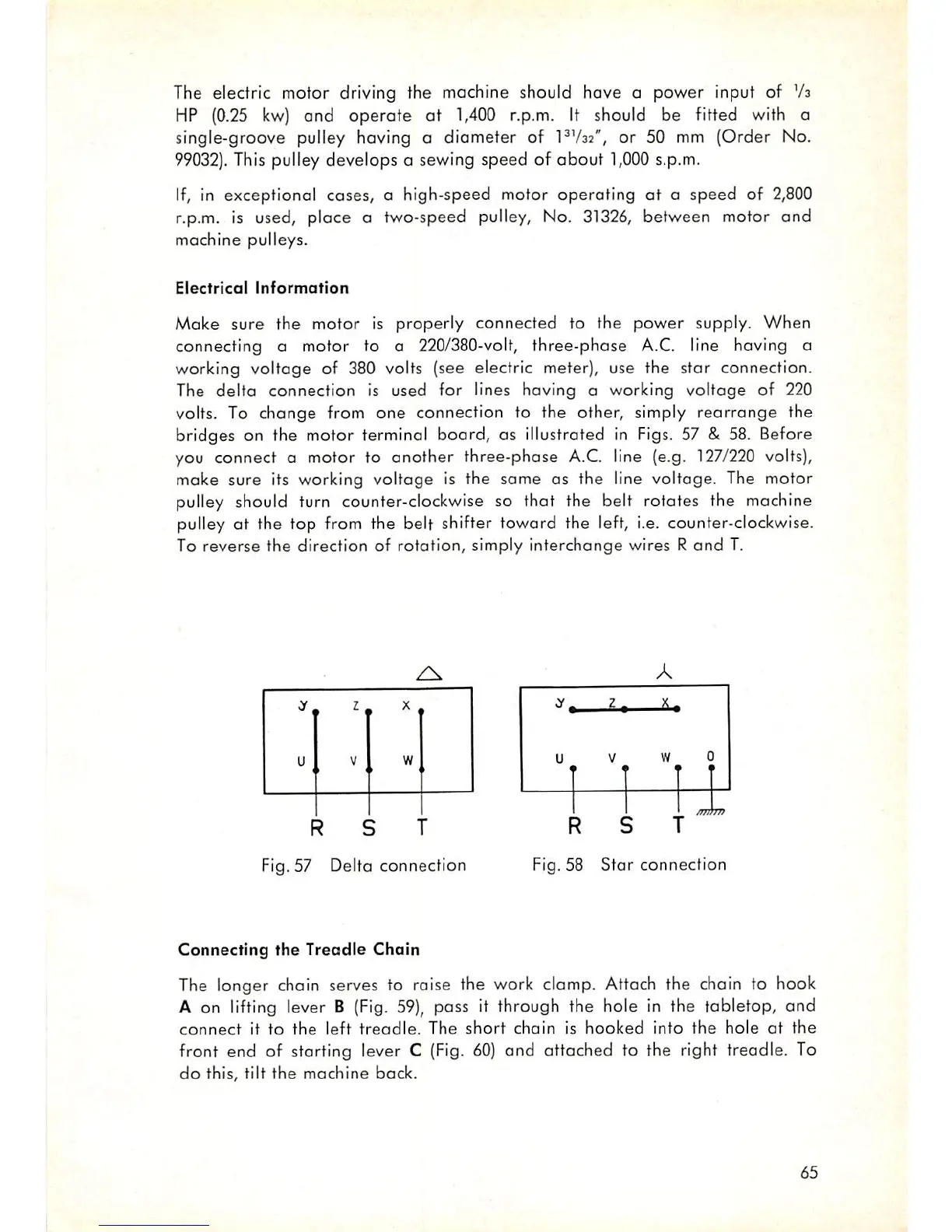

Make sure the motor is properly connected to the power supply. When

connecting a motor to a 220/380-volt, three-phase A.C. line having a

working voltage of 380 volts (see electric meter), use the star connection.

The

delta

connection is used for lines having a working

voltage

of 220

volts. To change from one connection to the other, simply

rearrange

the

bridges on the motor terminal board, as illustrated in Figs. 57 & 58. Before

you connect a motor to another three-phase

A.C.

line (e.g.

127/220

volts),

make sure its working voltage is the same as the line voltage. The motor

pulley should turn counter-clockwise so that the belt rotates the machine

pulley at the top from the belt shifter toward the left, i.e. counter-clockwise.

To

reverse

the

direction

of

rotation,

simply

interchange

wires R

and

T.

y

2 X

u

V w

f

Fig. 57 Delta connection

A

.Y, 2 ,

X.

U V

I

w

0

1

1

R

%

^

/fTJhTf

Fig. 58

Star

connection

Connecting

the

Treadle

Chain

The longer chain serves to raise the work clamp. Attach the chain to hook

A on

lifting

lever

B

(Fig.

59),

pass it

through

the hole in the tabletop, and

connect

it

to

the

left

treodle.

The

short

chain

is

hooked

into

the

hole

ot

the

front end of starting lever C

(Fig.

60)

and attached to the right treadle. To

do

this, tilt

the

machine

back.

65

Loading...

Loading...