Care and maintenance

10 - 1

These maintenance intervals apply to the average machine running time in sin-

gle-shift operation. If machine running times are increased, it is advisable to

shorten these intervals.

10.01 Cleaning the hook areas and the hooks

Switch the machine off!

Danger due to unintentional

starting of the machine!

Cleaning hook areas:

● Clean hook areas with a brush daily,

more frequently if in continuous

operation.

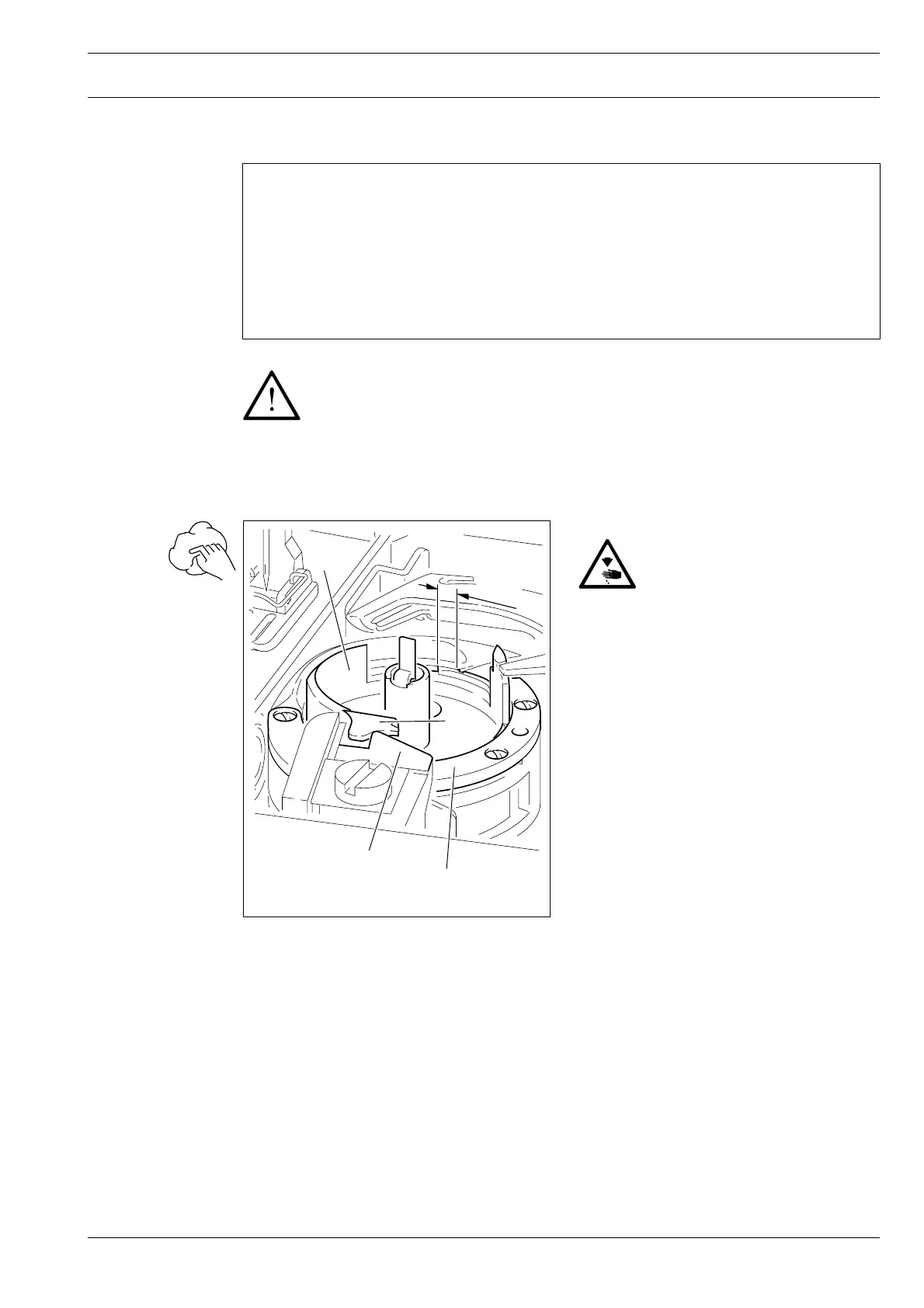

Cleaning hook

● Clean both hooks thoroughly once a

week; to do so, open hook cover.

● Set needle bar at its top position.

● Take out bobbin case together with

bobbin.

● Remove hook gib 1.

● Turn the balance wheel until the tip of the hook base enters the groove of the hook race

by about 5 mm, and take out hook base 2.

● Clean hook race with petroleum spirit.

● When inserting the hook base, make sure that lug 3 fits into the slot of positioning stop 4.

● Screw on hook gib 1.

● Insert bobbin case and close bed slide.

10 Care and maintenance

Clean hook areas ...................................daily, more frequently if in continuous operation

Check oil level (hook oil container) ................................................. daily, before operation

Check/adjust air pressure................................................................taily, before operation

Clean hook .................................................................................................once per week

Clean oil filter of air filter/regulator ............................................................. when required

Fig. 10 - 01

2

1

5 mm

3

4

Loading...

Loading...