34.

Zeroing

the

Top

and

Bottom

Feeds

Set

stitch length control n on 0 (Fig,

16).

Then rotate

the

balance

wheel and

check

to

see

that

the

vibrating presser

and

the

feed dog make no perceptible motion in

the

direction of

sewing.

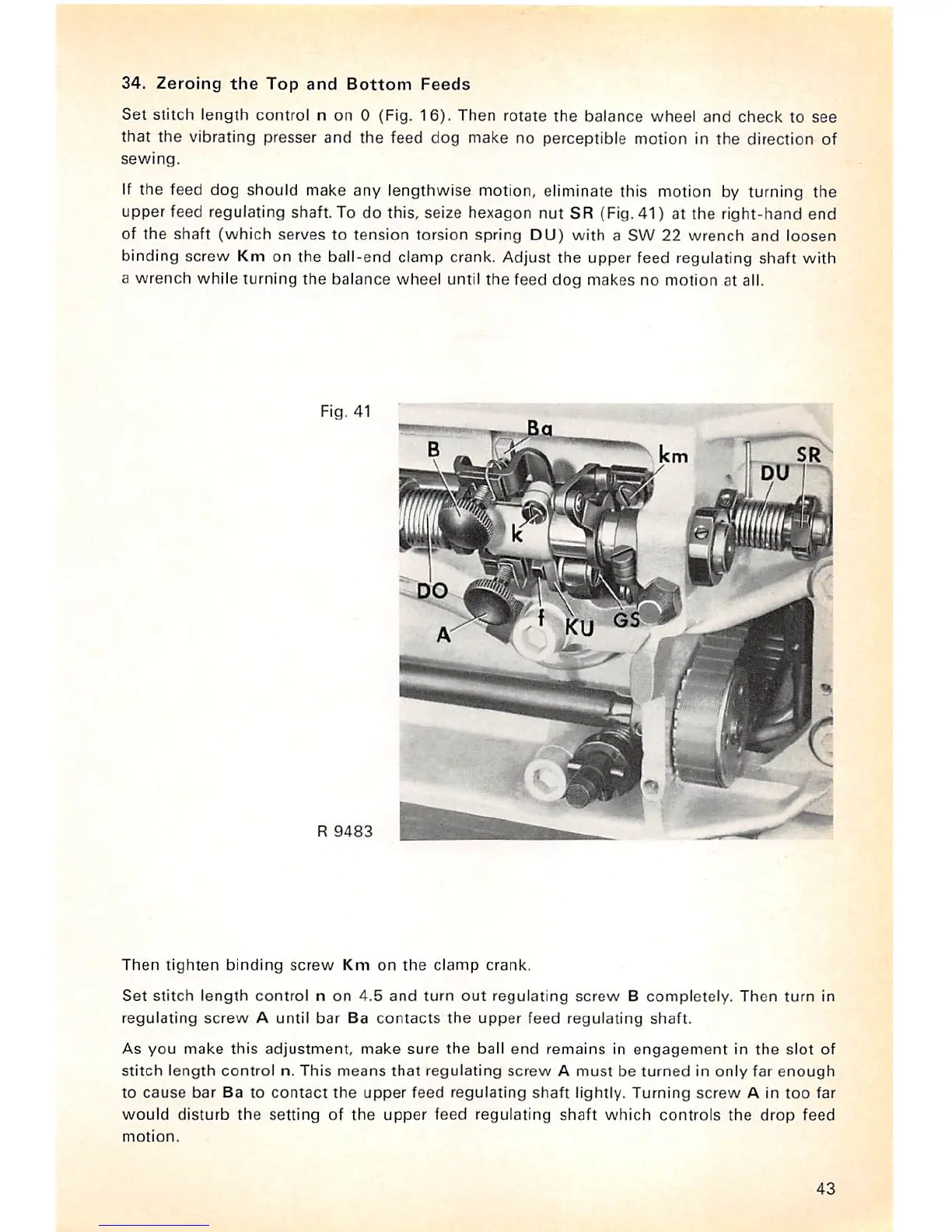

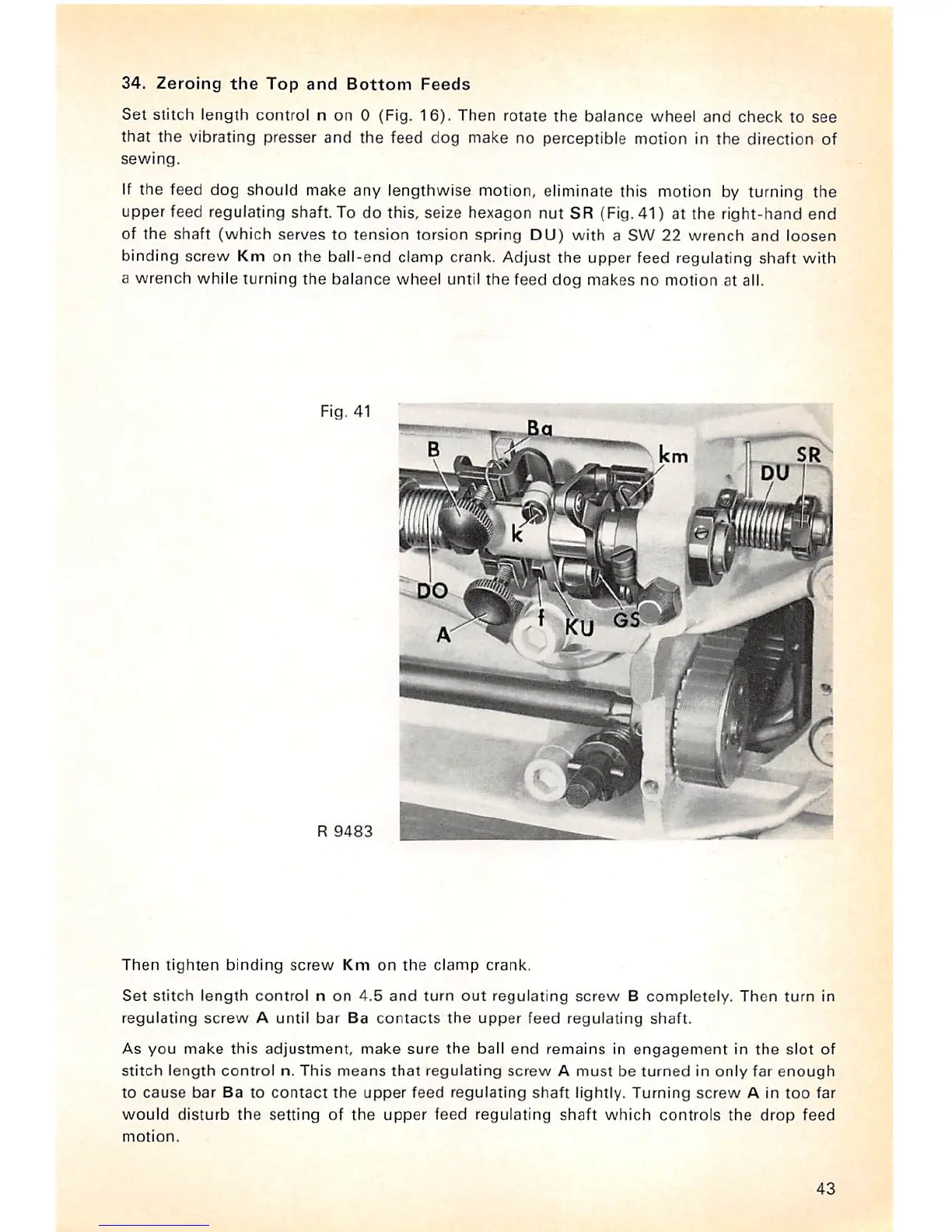

If the feed dog should make any lengthwise motion, eliminate this motion by turning the

upper

feed regulating shaft. To do this, seize hexagon nut SR (Fig. 41) at

the

right-hand

end

of

the

shaft

(which

serves

to

tension

torsion

spring

DU)

with

a

SW

22

wrench

and

loosen

binding screw Km on the ball-end clamp crank. Adjust the upper feed regulating shaft with

a

wrench

while turning

the

balance

wheel until

the

feed dog makes no motion at alt.

Fig. 41

B

R

9483

Then

tighten

binding

screw

Km

on

the

clamp

crank.

Set

stitch

length

control

n on

4.5

and

turn

out

regulating

screw

B

completely.

Then

turn

in

regulating

screw

A until

bar

Ba

contacts

the

upper

feed

regulating

shaft.

As

you

make

this

adjustment,

make

sure

the

ball

end

remains

In

engagement

in

the

slot

of

stitch

length

control

n.

This

means

that

regulating

screw

A

must

be

turned

in

only

far

enough

to

cause

bar

Ba

to

contact

the

upper

feed

regulating

shaft

lightly.

Turning

screw

A in

too

far

would

disturb

the

setting

of

the

upper

feed

regulating

shaft

which

controls

the

drop

feed

motion.

43

Loading...

Loading...