28.

Conversion

to

Another

Subclass

To convert

the

machine to

another

subclass, remove presser foot, needle plate and feed dog,

tilt

the

machine

back

and

strip

the

vibrating presser.

Relieve

the

pressure

of

the

presser

bar

spring

by

turning

out

pressure

regulating

screw

19

(Fig.

19).

Before you install a new vibrating presser,

check

to

see

that

the mounting surfaces on

the

bracket

and

on

the

vibrating

presser

are

clean.

Loosen binding screw K (Fig. 40) on the driving lever and check to make sure the vibrating

presser

works

smoothly.

The

guide

should

have

a

vertical

clearance

of

.004",

or 0.1

mm,

maximum.

Worn

connections

should

be replaced by new ones. As you replace the feed dog

and

the

needle

plate, make

sure

the

former

moves

freely in

the

feed

slots.

After all the parts replaced have

been

adjusted

correctly, reset

the

presser foot pressure.

29.

Setting

the

Feed

Dog

at

Correct

Height

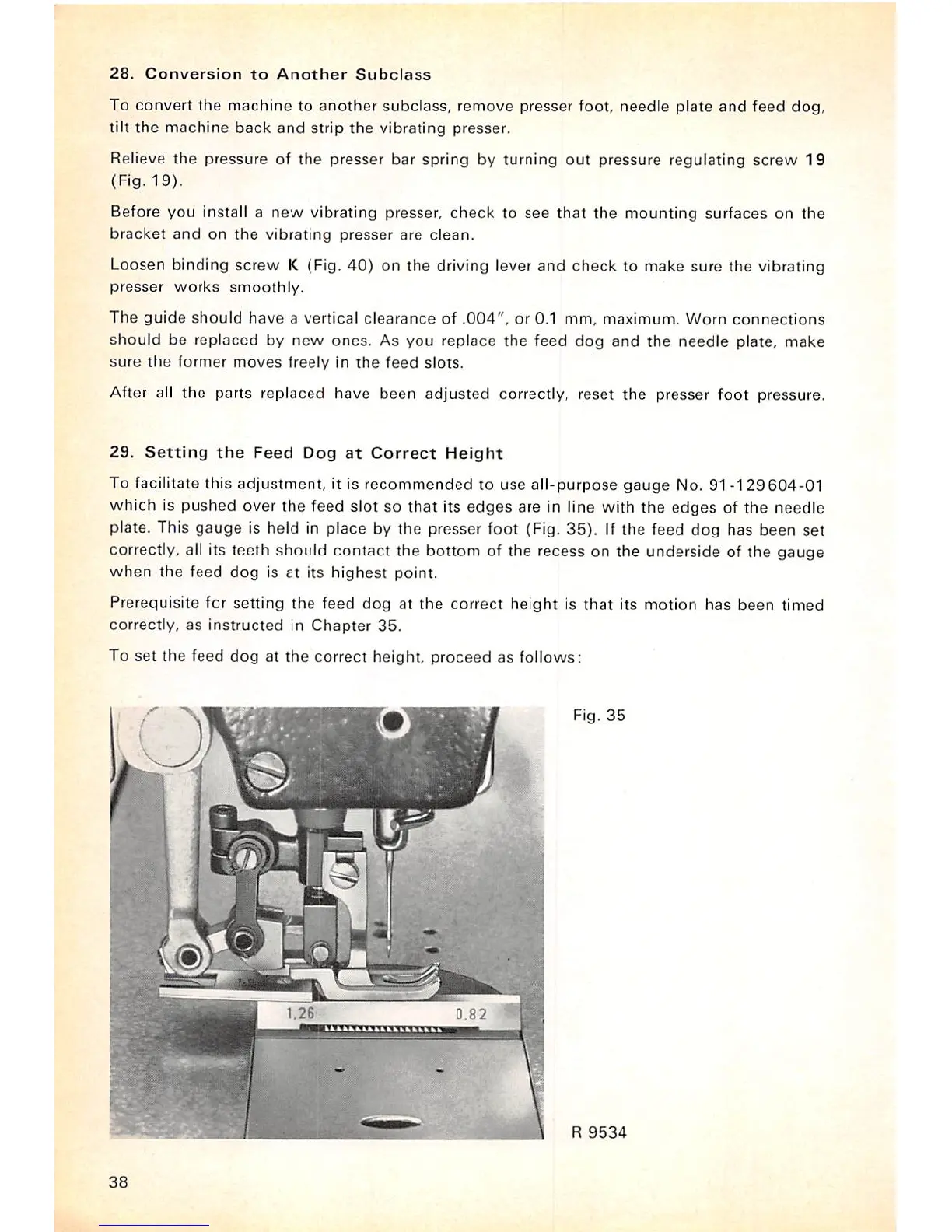

To facilitate this adjustment, it is recommended to use all-purpose gauge No. 91-129 604-01

which is pushed over the feed slot so that its

edges

are in line with the

edges

of the needle

plate. This

gauge

is held in place by the presser foot (Fig. 35). If

the

feed

dog

has

been

set

correctly, all its teeth should contact the bottom of the recess on the underside of the gauge

when

the

feed

dog

is at its

highest

point.

Prerequisite

for

setting

the

feed

dog

at

the

correct

height

is

that

its

motion

has

been

timed

correctly, as

instructed

in

Chapter

35.

To

set

the

feed

dog

at

the

correct

height,

proceed

as

follows:

Fig.

35

R

9534

38

Loading...

Loading...