Push

the

shaft

toward

the

right

and

tighten

binding

screw

9 on

clamp

crank

K9

securely.

Set

the

machine

for its

longest

stitch,

turn

the

balance

wheel

and

check

to

see

that

the

feed

rock

shaft

crank

is

not

distorted

on its

shaft

and

the

feed

dog

is

centered

in

the

feed

slot.

Tighten

binding

screws

u

and

v

securely.

30.

Adjusting

the

Presser

Foot

When

you

mount

the

presser

foot

on

the

machine,

push

it up

against

the

bracket

as

far

as

it

will

go,

then

tighten

the

set

screw

securely.

When

the

presser

bar is raised, i.e.

the

presser

bar

lifter is flicked to

the

left,

there

should

be

a

clearance

of

about

^/i6", or

5.0

mm,

between

presser

foot

and

needle

plate

and

the

needle

should

be

centered

in

the

needle

hole

of

the

presser

foot.

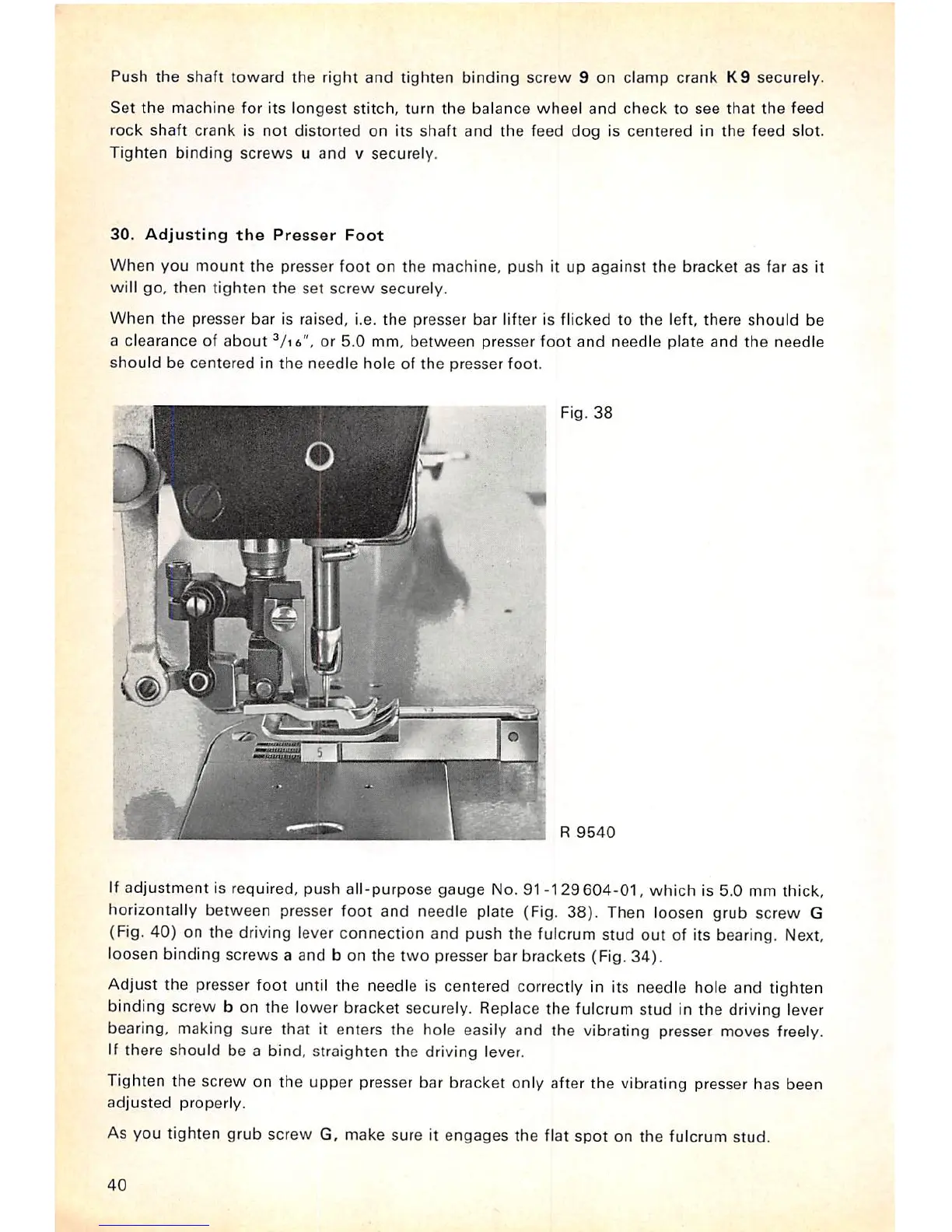

Fig.

38

1

R

9540

If adjustment is required, push all-purpose gauge No. 91

-129604-01,

which is 5.0 mm thick,

horizontally between presser foot and needle plate (Fig. 38). Then loosen grub screw G

(Fig. 40) on the driving lever connection and push the fulcrum stud out of its bearing. Next,

loosen binding screws a and b on the two presser bar brackets (Fig. 34).

Adjust the presser foot until the needle is centered correctly in its needle hole and tighten

binding screw b on the lower bracket securely. Replace the fulcrum stud in the driving lever

bearing, making sure that it enters the hole easily and the vibrating presser moves freely.

If there should be a bind, straighten the driving lever.

Tighten the screw on the upper presser bar bracket only after the vibrating presser has been

adjusted

properly.

As you tighten grub

screw

G, make sure it

engages

the

flat

spot

on the fulcrum stud.

40

Loading...

Loading...