The

lifting

motion

of

the

vibrating

presser

should

be

timed

so

that

the

latter

descends

onto

the

material perpendicularly from above when the feed points of the rising feed dog are flush

with the surface of the needle plate. This setting

should

remain the same, regardless of

the

top feed stroke set. The vibrating presser

should

remain in

engagement

with

the

material

throughout

its feed stroke,

and

at the

end

of its stroke

should

rise perpendicularly again.

The perpendicular motion at

the

beginning of its feeding action

should

be twice as large as

that

at

the

end

of

its

stroke.

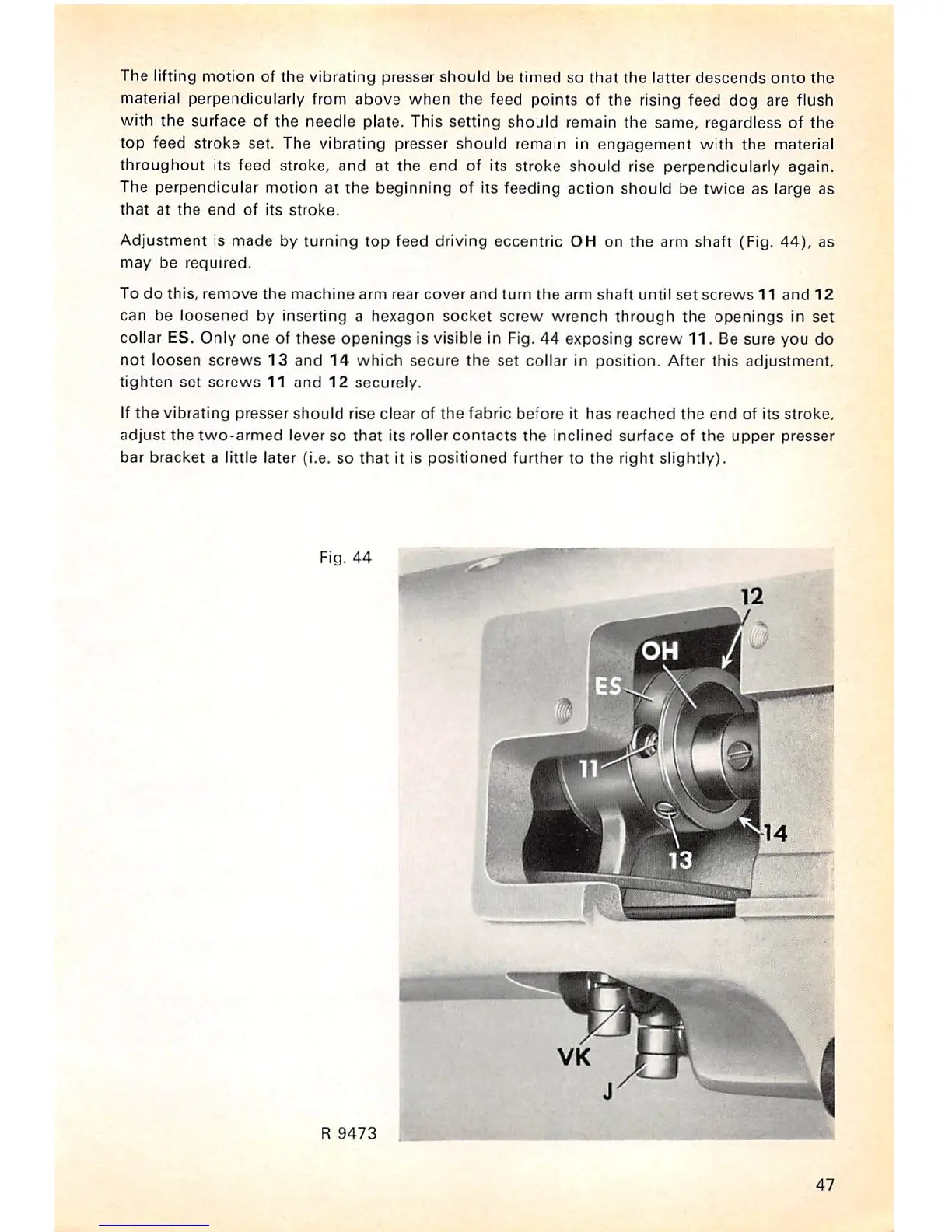

Adjustment is

made

by turning top feed driving eccentric OH on

the

arm

shaft

(Fig.

44),

as

may

be

required.

To

do

this,

remove

the

machine

arm

rear

cover

and

turn

the

arm

shaft

until

set

screws

11

and

12

can

be

loosened

by inserting a

hexagon

socket

screw

wrench

through

the

openings

in

set

collar

ES.

Only

one

of

these

openings

is visible in Fig.

44

exposing

screw

11.

Be

sure

you

do

not loosen

screws

13

and

14

which

secure

the

set

collar In position. After this adjustment,

tighten

set

screws

11

and

12

securely.

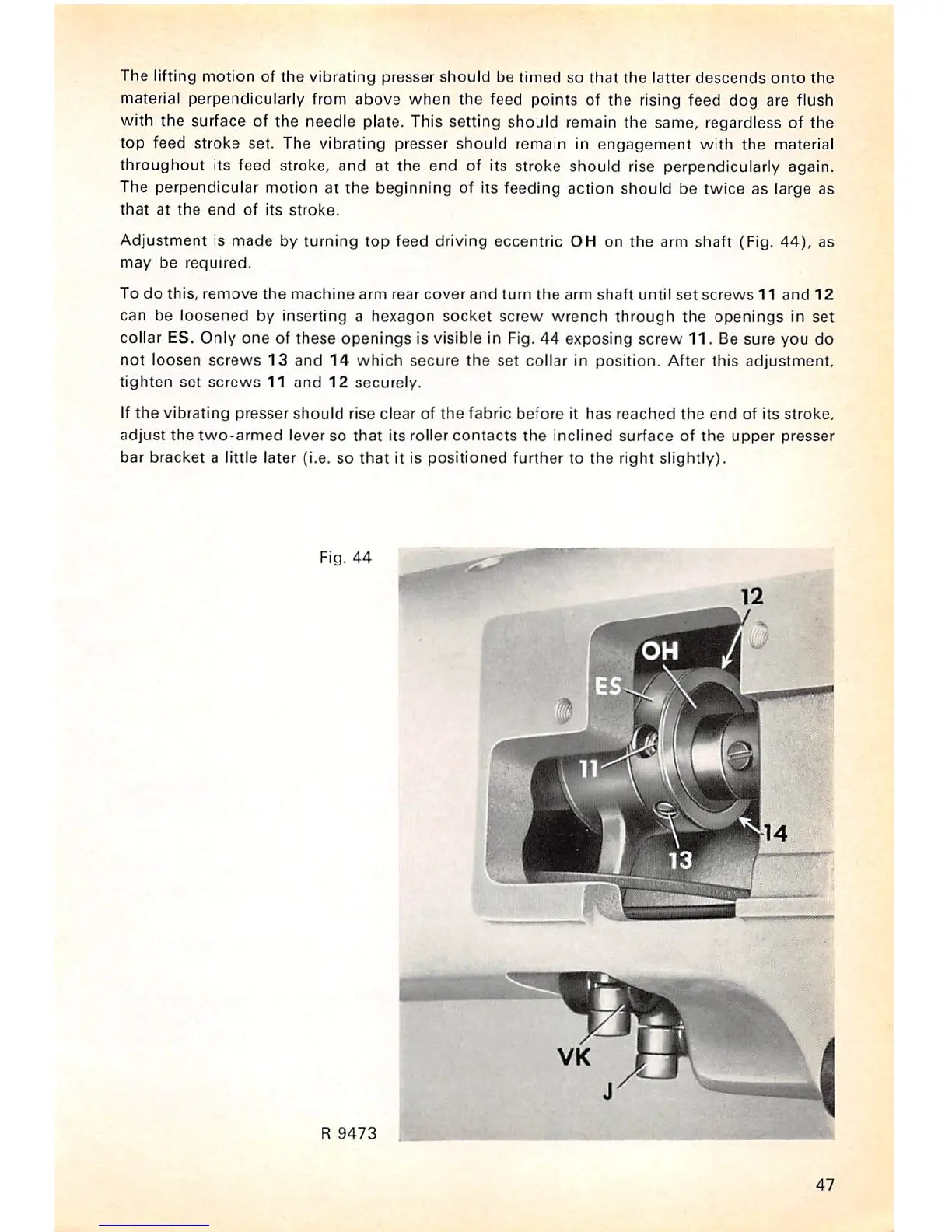

If

the

vibrating

presser

should

rise

clear

of

the

fabric

before

it

has

reached

the

end

of

its

stroke,

adjust

the

two-armed

lever

so

that

its

roller

contacts

the

inclined

surface

of

the

upper

presser

bar bracket a little later (i.e. so

that

it is positioned further to

the

right slightly).

Fig.

44

R

9473

47

Loading...

Loading...