Adjustment

2 - 21

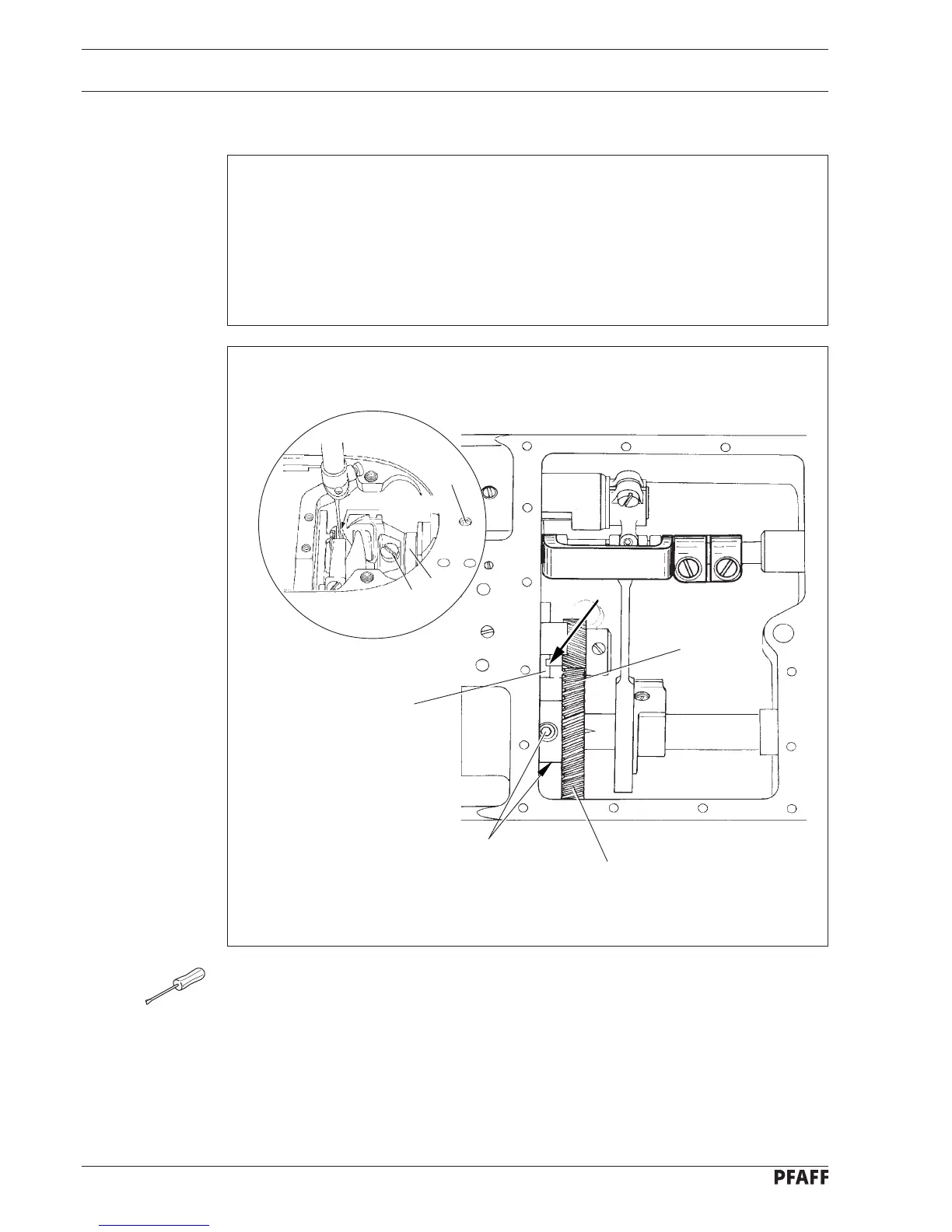

● Loosen screws 1 and 2.

● Turn bearing 3 according to Requirement 1.

● Move hook lightly against thrower 4, position bearing 3, without turning it, according to

Requirement 2 and tighten screws 1 and 2.

● Position gear 5 (screws 6) according to Requirement 3.

Fig. 2 - 20

2.22 Eccentric hook shaft bearing

Requirement

1. The slot in bearing 3 must be visible from the underside.

There must be a very slight, but still perceivable, play between gears 5 and 7.

2. When the hook is resting lightly against thrower 4 and the hook point is at the needle

centre, there must be a clearance of less than 0.1 mm between hook point and

clearance cut.

3. Gear 5 must be aligned with gear 7.

3

5

7

6

4

2

max. 0,1 mm

1

Loading...

Loading...