4.9 Connecting the electrical supply

DANGER

Danger to life from electric shock

Touching exposed and voltage-bearing elements causes an electric shock. Improper connection of

the mains supply leads to the risk of touchable live housing parts. There is a risk to life.

►

Before the installation, check that the connection leads are voltage-free.

►

Make sure that electrical installations are only carried out by qualified electricians.

►

Provide adequate grounding for the device.

►

After connection work, carry out an earthed conductor check.

WARNING

Risk of injury due to incorrect installation

Dangerous situations may arise from unsafe or incorrect installation.

►

Do not carry out your own conversions or modifications on the unit.

►

Ensure the integration into an Emergency Off safety circuit.

WARNING

Risk of danger to life through missing mains disconnection device

The vacuum pump and electronic drive unit are not equipped with a mains disconnection device

(mains switch).

►

Install a mains disconnection device according to SEMI-S2.

►

Install a circuit breaker with an interruption rating of at least 10,000 A.

4.9.1 Grounding unit

Required aids

●

Screw M4 × 8

●

Shake proof washer M4, if required

●

Suitable grounding cable with cable lug size M4

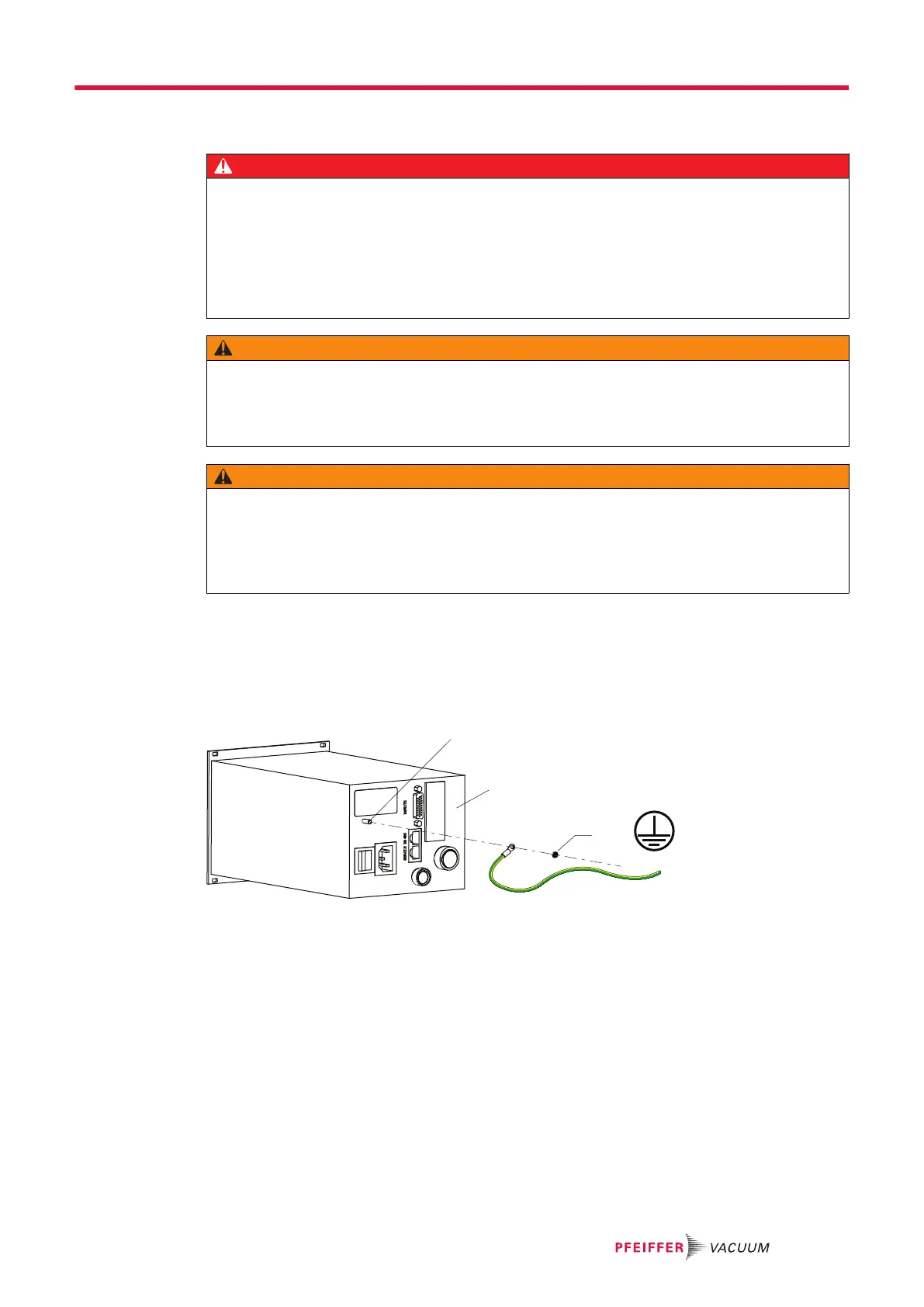

AC INPUT

GAUGE

PUMP

POWER

M4

1

2

Fig. 8: Connection of the grounding cable to the TCP 350

1 Ground terminal 2 Rear of housing

●

The grounding connection is mandatory for the TCP 350 in order to discharge applicative interfer-

ences.

●

Alternatively, the TCP 350 is grounded following installation in a rack.

Procedure

1. Use the grounding connection at the rear of the device (M4 stud bolt).

2. Route the connection in accordance with locally applicable provisions.

4.9.2 Connecting to mains power supply

Establishing mains supply

1. Make sure that the "POWER" main switch of the power supply pack is switched off prior to con-

nection.

2. Always ensure a secure connection to the earthed conductor (PE), protection class I.

Installation

25/56

Loading...

Loading...