Revision: 3.0.3

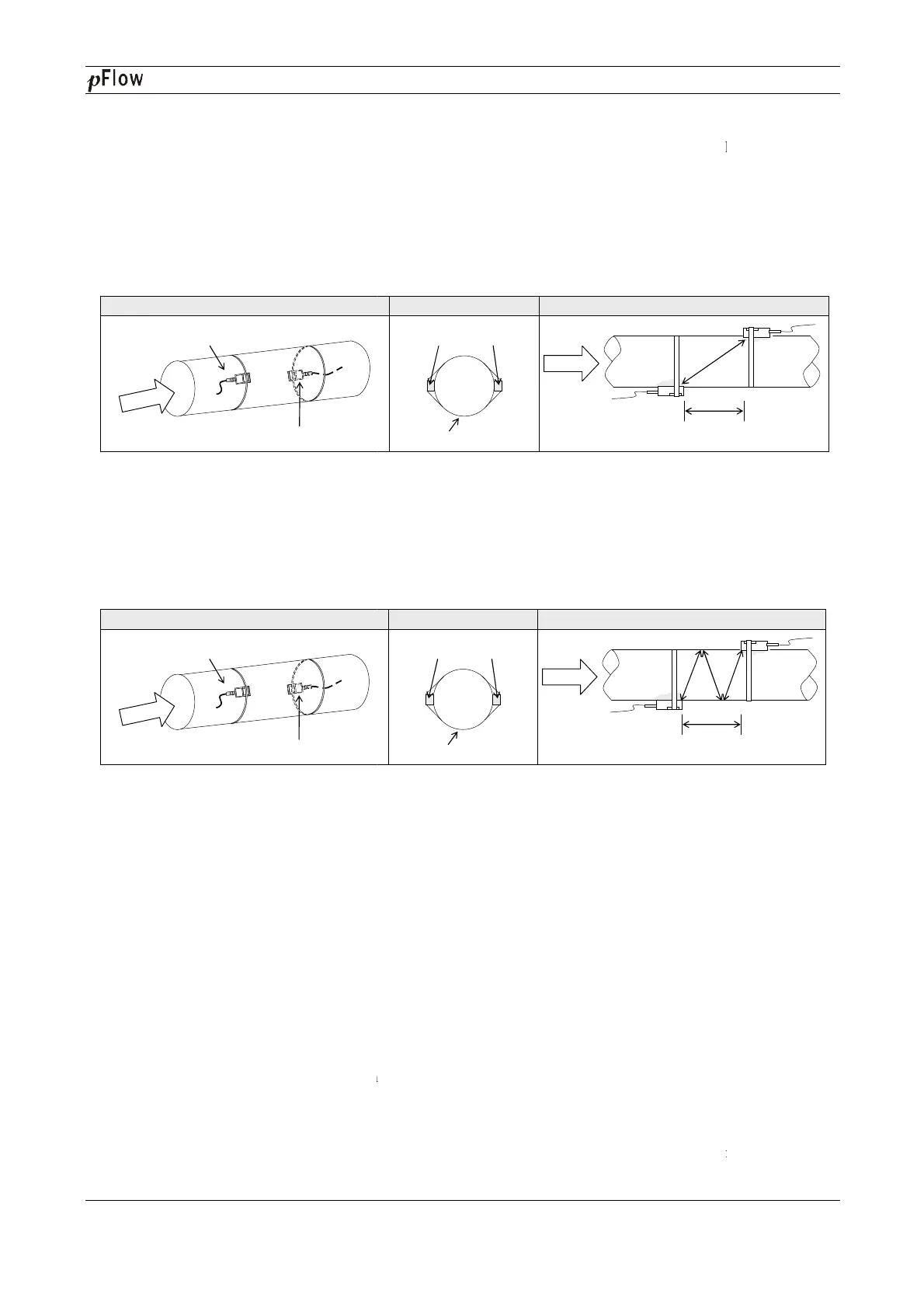

4.1.4 Z Method

The signal transmitted in a Z method installation has less

when the pipes are too large, there are some suspended solid in the fluid, or the

This is because the Z method utilizes a directly transmitted (rather than reflected)

liquid only once.

The Z method is able to measure on pipe diameters ranging from 100mm to

Therefore, we recommend the Z method for pipe diameters over 300mm (12

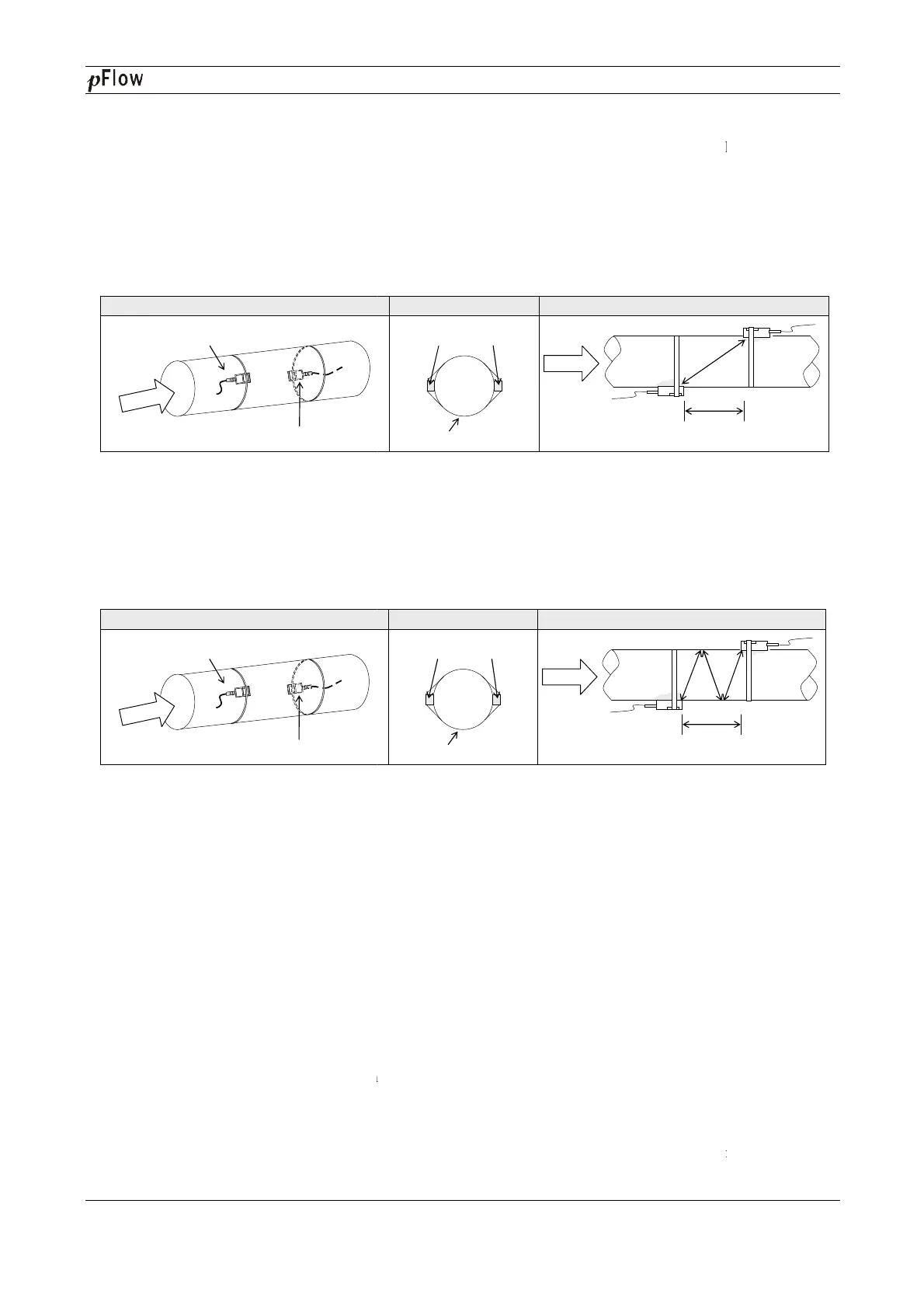

4.1.5

N Method (not commonly used)

With the N method, the sound waves traverse the fluid

suitable for small pipe diameter measurement.

The measurement accuracy can be improved by extending the transit distance with the N method (uncommo

used).

4.2

Transducer Mounting Inspection

Check to see if the transducer is installed properly and if there is an accurate and strong enough ultrasonic signal

to ensure proper operation and high reliability of the transducer. It can be confirmed by chec

signal strength, total transit time, delta time as well as transit time ratio.

The "mounting"

condition directly influences the flow value accuracy and system long

most instances, only apply a wide ban

stick it to the outside pipe wall to get good measurement results. However, the following inspections still need to

be carried out in order to ensure the high reliability of the measurement

4.2.1 Signal Strength

Signal strength (displayed in Window M90) indicates a detected strength of the signal both from upstream and

downstream directions. The relevant signal strength is indicated by numbers from 00.0

signal detected while 99.9 represents

Normally, the stronger the signal strength detected, the longer the operation of the instrument reliably, as well as

the more stable the measurement value obtained.

Adjust the transducer to the best position and check to ensure that enough sonic coupling compound is applied

adequately during installation in order to obtain the maximum signal strength.

Upstream Transducer

Flow

Side View

Upstream Transducer

Flow

Side View

D116

Series Ultrasonic Flowmeter

The signal transmitted in a Z method installation has less

attenuation than a signal transmitted with the V method

when the pipes are too large, there are some suspended solid in the fluid, or the

scaling

This is because the Z method utilizes a directly transmitted (rather than reflected)

signal which transverses the

The Z method is able to measure on pipe diameters ranging from 100mm to

800mm (4〞~32〞

Therefore, we recommend the Z method for pipe diameters over 300mm (12

〞).

N Method (not commonly used)

With the N method, the sound waves traverse the fluid

three times and bounce twice

off the pipe walls. It is

suitable for small pipe diameter measurement.

The measurement accuracy can be improved by extending the transit distance with the N method (uncommo

Transducer Mounting Inspection

Check to see if the transducer is installed properly and if there is an accurate and strong enough ultrasonic signal

to ensure proper operation and high reliability of the transducer. It can be confirmed by chec

signal strength, total transit time, delta time as well as transit time ratio.

condition directly influences the flow value accuracy and system long

-

time running reliability. In

ic coupling compound lengthwise on the face of the transducer and

stick it to the outside pipe wall to get good measurement results. However, the following inspections still need to

be carried out in order to ensure the high reliability of the measurement

and long-

term operation of the instrument.

Signal strength (displayed in Window M90) indicates a detected strength of the signal both from upstream and

downstream directions. The relevant signal strength is indicated by numbers from 00.0

~99

Normally, the stronger the signal strength detected, the longer the operation of the instrument reliably, as well as

the more stable the measurement value obtained.

Adjust the transducer to the best position and check to ensure that enough sonic coupling compound is applied

adequately during installation in order to obtain the maximum signal strength.

Flow

Top ViewSection

Pipe Strap

Transducer

Flow

Top ViewSection

Pipe Strap

Transducer

Series Ultrasonic Flowmeter

Page 16 of 53

attenuation than a signal transmitted with the V method

.

signal which transverses the

off the pipe walls. It is

The measurement accuracy can be improved by extending the transit distance with the N method (uncommo

nly

Check to see if the transducer is installed properly and if there is an accurate and strong enough ultrasonic signal

time running reliability. In

ic coupling compound lengthwise on the face of the transducer and

stick it to the outside pipe wall to get good measurement results. However, the following inspections still need to

term operation of the instrument.

Signal strength (displayed in Window M90) indicates a detected strength of the signal both from upstream and

Normally, the stronger the signal strength detected, the longer the operation of the instrument reliably, as well as

Adjust the transducer to the best position and check to ensure that enough sonic coupling compound is applied

Loading...

Loading...