Revision: 3.0.3

1.3 Powering on

As soon as the Flowmeter is switched on, the self

error code will display on the screen (Refer

automatically according to the last input parameters.

If the installation is accomplished when system is switched on, gain adjustment can be mo

After S1, S2, S3, S4 are displayed on the upper left corner of the screen, the system will activate the normal

measurement condition automatically. It is indicated by code

If it is the fir

st time to use or install on a new site, the customer need to input the new installation site

The system will default to the last window settings and automatically display the

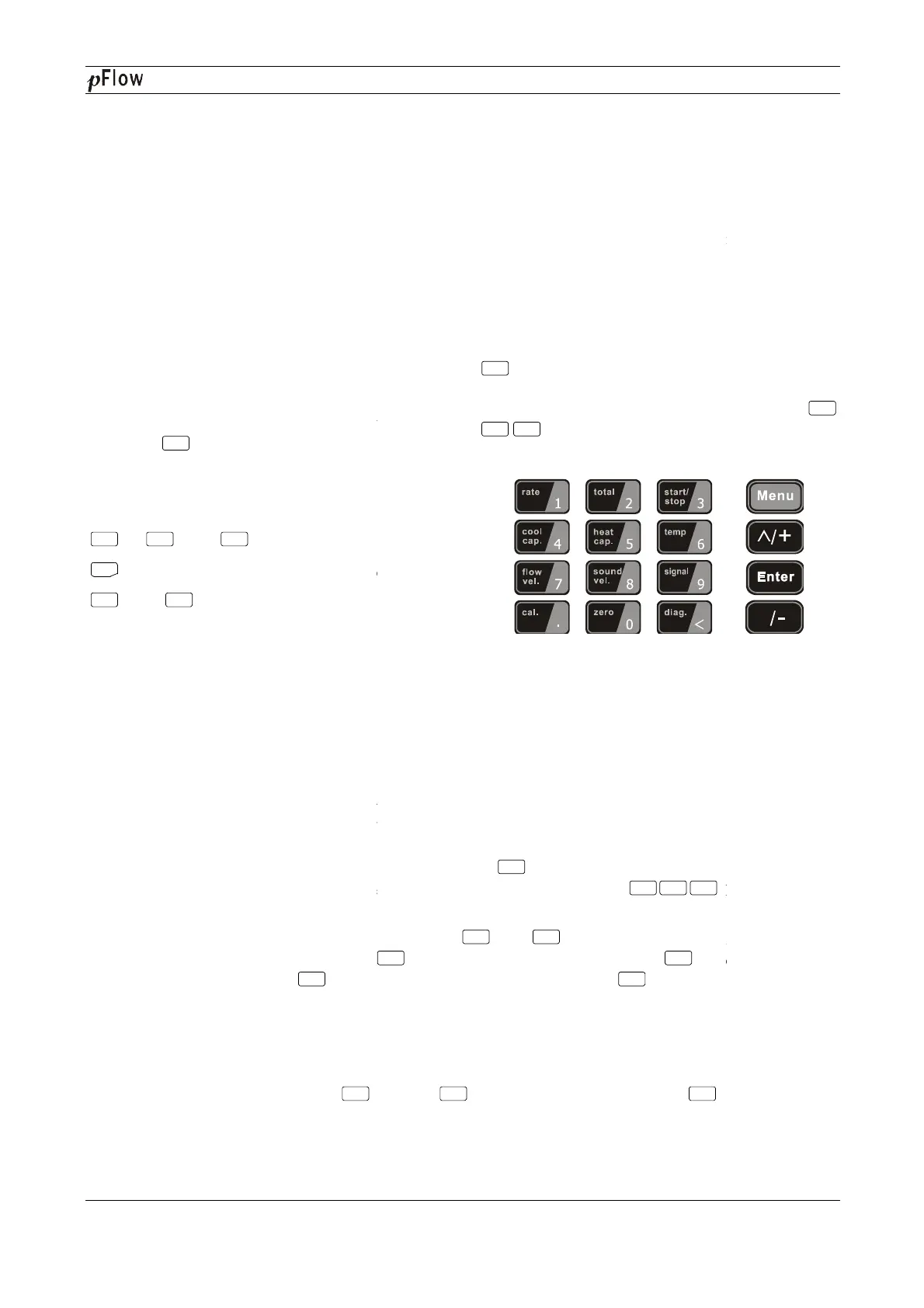

1.4 Keypad Functions

This keypad is dual function keypad:

1. When separately pressed, is shortcut function,

referring to "2. Quickly set menu

2. Press

and Number key, is Menu key,

referring to"6.Menu Window Description".

Follow these guidelines when using the Flowmeter

keypad (Refer to Keypad Figure):

~ And To input numbers.

Backspace or delete characters to the left.

And

Return to the last menu or to open

the next menu. Acts as "+" and "-"

entering numbers.

1.5 Keypad Operation

The flow meter adopts the window software design to consolidate or subdivide all of the parameters entered, the

instrument setup and measurement result displays into more than 100 independent windows. The operator ca

input parameters, modify settings or display measurement results by "visiting" a specific window. These windows

are arranged by 2-

digit serial numbers (including "+" sign) from 00~99, then to +0, +1, etc. Each window serial

number, or so-called window ID

code, has a defined meaning. For example, Window M11 indicates the parameter

input for pipe outside diameter, while Window M25 indicates the mounting spacing between the transducers, etc.

(Refer –

Windows Display Explanations).

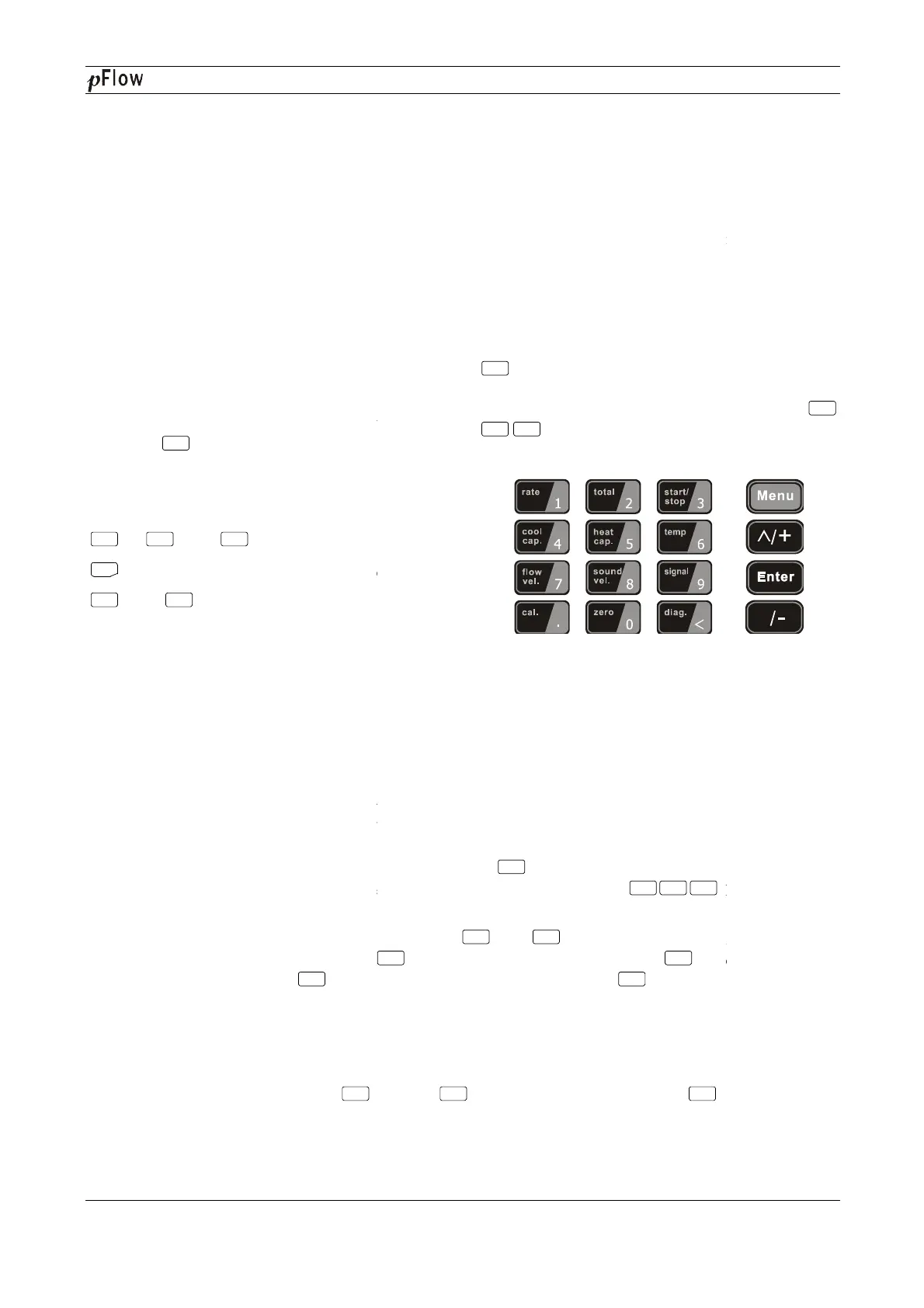

The keypad shortcut to visi

t a specific window is to press the

ID code. For example, to input or check the pipe outside diameter, just press the

ID code 11.

Another method to visit a particular window is to press

the current window ID code is M02, press

Window M00; then, press the

key to back Window M01, and press the

M02.

Win

dows are separated into three types: (1) Data Type, such as M11, M12; (2) Option Type, such as M14; (3)

Pure Display Type, such as M01, M00.

You can check the corresponding parameters by visiting the Data Type Windows. If you want to m

parameters, input the digits and press

Menu

0 9

●

<

^

^

^

Enter

D116

Series Ultrasonic Flowmeter

As soon as the Flowmeter is switched on, the self

-

diagnosis program will start to run. If any error is detected, a

error code will display on the screen (Refer

- Error Diagnoses). After that self-

diagnosis, the system will run

automatically according to the last input parameters.

If the installation is accomplished when system is switched on, gain adjustment can be mo

After S1, S2, S3, S4 are displayed on the upper left corner of the screen, the system will activate the normal

measurement condition automatically. It is indicated by code

"*R"

on the upper left corner of the screen.

st time to use or install on a new site, the customer need to input the new installation site

The system will default to the last window settings and automatically display the

m

1. When separately pressed, is shortcut function,

";

and Number key, is Menu key,

Follow these guidelines when using the Flowmeter

Backspace or delete characters to the left.

Return to the last menu or to open

Select a menu. Press this key fir

menu numbers and then enter the selected menu. For

example, to input a pipe outside diameter, press

keys, where "11"

display the parameter for pipe outside diameter.

The flow meter adopts the window software design to consolidate or subdivide all of the parameters entered, the

instrument setup and measurement result displays into more than 100 independent windows. The operator ca

input parameters, modify settings or display measurement results by "visiting" a specific window. These windows

digit serial numbers (including "+" sign) from 00~99, then to +0, +1, etc. Each window serial

code, has a defined meaning. For example, Window M11 indicates the parameter

input for pipe outside diameter, while Window M25 indicates the mounting spacing between the transducers, etc.

Windows Display Explanations).

t a specific window is to press the

key at any time, then input the 2

ID code. For example, to input or check the pipe outside diameter, just press the

Another method to visit a particular window is to press

and

keys to scroll the screen. For example, if

key to enter Window M01, press the

key to back Window M01, and press the

key again to enter Window

dows are separated into three types: (1) Data Type, such as M11, M12; (2) Option Type, such as M14; (3)

You can check the corresponding parameters by visiting the Data Type Windows. If you want to m

or press first, input the digits then press

Menu

1 1

Menu

Menu

1 1

^

^

^ ^

^

Enter Enter

Series Ultrasonic Flowmeter

Page 9 of 53

diagnosis program will start to run. If any error is detected, a

n

diagnosis, the system will run

After S1, S2, S3, S4 are displayed on the upper left corner of the screen, the system will activate the normal

on the upper left corner of the screen.

st time to use or install on a new site, the customer need to input the new installation site

parameters.

Select a menu. Press this key fir

st, input two

menu numbers and then enter the selected menu. For

example, to input a pipe outside diameter, press

display the parameter for pipe outside diameter.

The flow meter adopts the window software design to consolidate or subdivide all of the parameters entered, the

instrument setup and measurement result displays into more than 100 independent windows. The operator ca

n

input parameters, modify settings or display measurement results by "visiting" a specific window. These windows

digit serial numbers (including "+" sign) from 00~99, then to +0, +1, etc. Each window serial

code, has a defined meaning. For example, Window M11 indicates the parameter

input for pipe outside diameter, while Window M25 indicates the mounting spacing between the transducers, etc.

key at any time, then input the 2

-digit window

keys to scroll the screen. For example, if

key again to enter Window

dows are separated into three types: (1) Data Type, such as M11, M12; (2) Option Type, such as M14; (3)

You can check the corresponding parameters by visiting the Data Type Windows. If you want to m

odify the

Menu

Loading...

Loading...