Revision: 3.0.3

11 Appendix3-

11.1

RTD Energy Meter Function

This function is applied to the following meter and measurement temperature range:

D116 Hot(Cold) Energy Meter:0~100 ℃

,equipped with PT1000 temperature sensor.

The RTD Module’s main function is to input the temperature values for the energy measurement. The

automatically calculate the caloric content of water at different temperatures

value and totalized energy value.

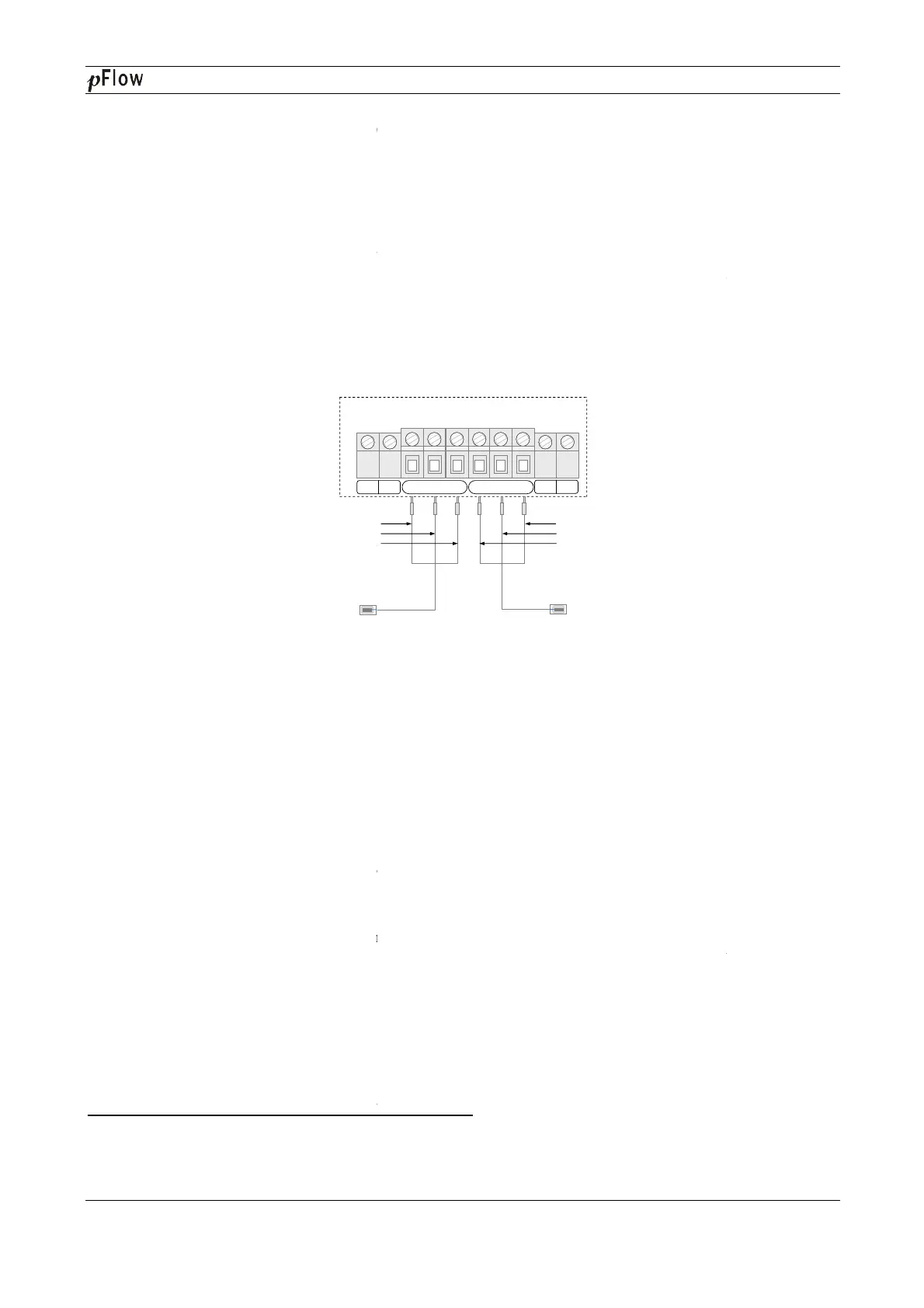

11.2 Wiring(PT1000)

Three-wire connections methods is used

for the RTD module and PT100

methods

is as follows.(Note: A1, A2, B1, B2 are the same color, C1 an

The two PT1000

temperature sensors are installed on the inlet and return pipes and they will input temperature

signals to the D116 transmitter.

11.3

Energy Measurement Methods

Energy Measurement Methods:

Formula 2: Q= m (h1-h2)

Q—Energy Value

m—

quality of the medium( density

h1—

enthalpy value of the inlet water

h2—

enthalpy value of the return water

The temperature and pressure at the inlet and return water points can be measured by temperature sensors

transmitter, and pressure sensors and a transmitter. Then the enthalpy value at the inlet and return water points can

be calculated through the enthalpy values table. The flow of the medium can be measured via the ultrasonic flow

sensors and D116 tra

nsmitter, and the caloric value can be derived according to the above formulas and the caloric

calibration index.

11.4 Temperature

There are two methods to calibrate the RTD module (customers can choose the proper one to calibrate according

to the actual situation).

Method One: Resistance box calibration method

Note: The purpose is to calibrate the internal circuit of RTD module

Tools needed: one DC resistance box, 3 wires (each wire less than 40mm long), and an instrument screwdriver.

4mA

White

Red

D116

Series Ultrasonic Flowmeter

0 Wiring (Module o

RTD Energy Meter Function

This function is applied to the following meter and measurement temperature range:

,equipped with PT1000 temperature sensor.

The RTD Module’s main function is to input the temperature values for the energy measurement. The

automatically calculate the caloric content of water at different temperatures

and deriving an instantaneous energy

for the RTD module and PT100

0 temperature sensors,

is as follows.(Note: A1, A2, B1, B2 are the same color, C1 an

d C2 are the same color).

temperature sensors are installed on the inlet and return pipes and they will input temperature

Energy Measurement Methods

quality of the medium( density

×

transit time water volume)

enthalpy value of the inlet water

enthalpy value of the return water

The temperature and pressure at the inlet and return water points can be measured by temperature sensors

transmitter, and pressure sensors and a transmitter. Then the enthalpy value at the inlet and return water points can

be calculated through the enthalpy values table. The flow of the medium can be measured via the ultrasonic flow

nsmitter, and the caloric value can be derived according to the above formulas and the caloric

There are two methods to calibrate the RTD module (customers can choose the proper one to calibrate according

Method One: Resistance box calibration method

Note: The purpose is to calibrate the internal circuit of RTD module

Tools needed: one DC resistance box, 3 wires (each wire less than 40mm long), and an instrument screwdriver.

A1 B1 B1 A2 B2 B2

20mA 4mA 20mA

Return port

Red

Black

White

PT1000

Three Wires Connection

Series Ultrasonic Flowmeter

Page 51 of 53

The RTD Module’s main function is to input the temperature values for the energy measurement. The

D116 can

and deriving an instantaneous energy

temperature sensors are installed on the inlet and return pipes and they will input temperature

The temperature and pressure at the inlet and return water points can be measured by temperature sensors

and a

transmitter, and pressure sensors and a transmitter. Then the enthalpy value at the inlet and return water points can

be calculated through the enthalpy values table. The flow of the medium can be measured via the ultrasonic flow

nsmitter, and the caloric value can be derived according to the above formulas and the caloric

There are two methods to calibrate the RTD module (customers can choose the proper one to calibrate according

Tools needed: one DC resistance box, 3 wires (each wire less than 40mm long), and an instrument screwdriver.

Loading...

Loading...