Revision: 3.0.3

10.4

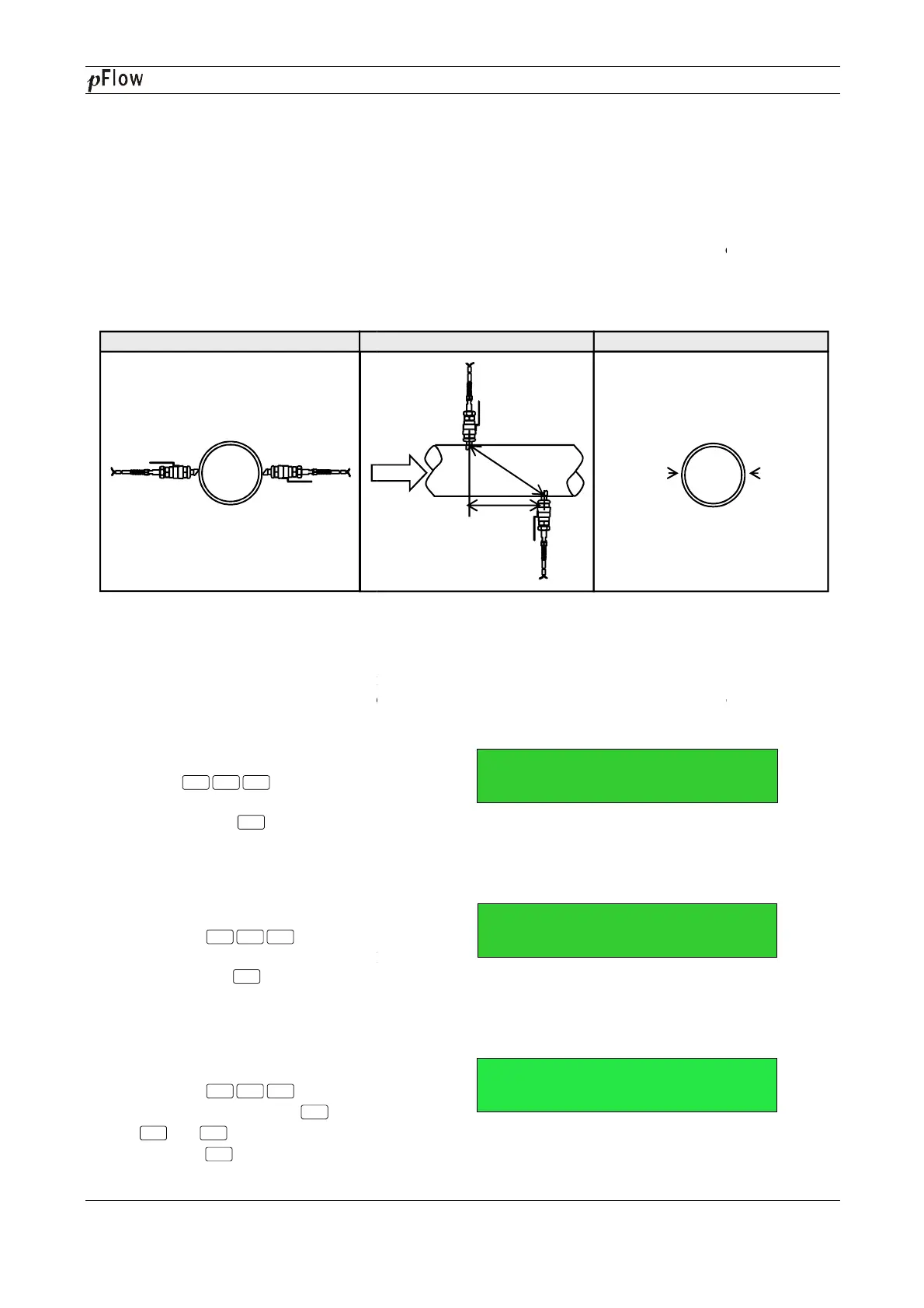

Transducer Mounting Methods

W211

insertion transducer mounting method: Z method through M24, it should be installed according to the

specific application condition.

10.4.1 Z Mounting Method

Z method is the most commonly used mounting met

diameters ranging from 50mm to 12

00mm. Due to strong signal strength and high measurement accuracy, the Z

method is preferable for pipe sections severely rusted or with too much scale formatio

installing the transducer using the Z method, be sure that the two transducers and the pipeline center axis are in

the same plane, but never in the 6 or 12 o’

clock positions. see below:

10.4.2

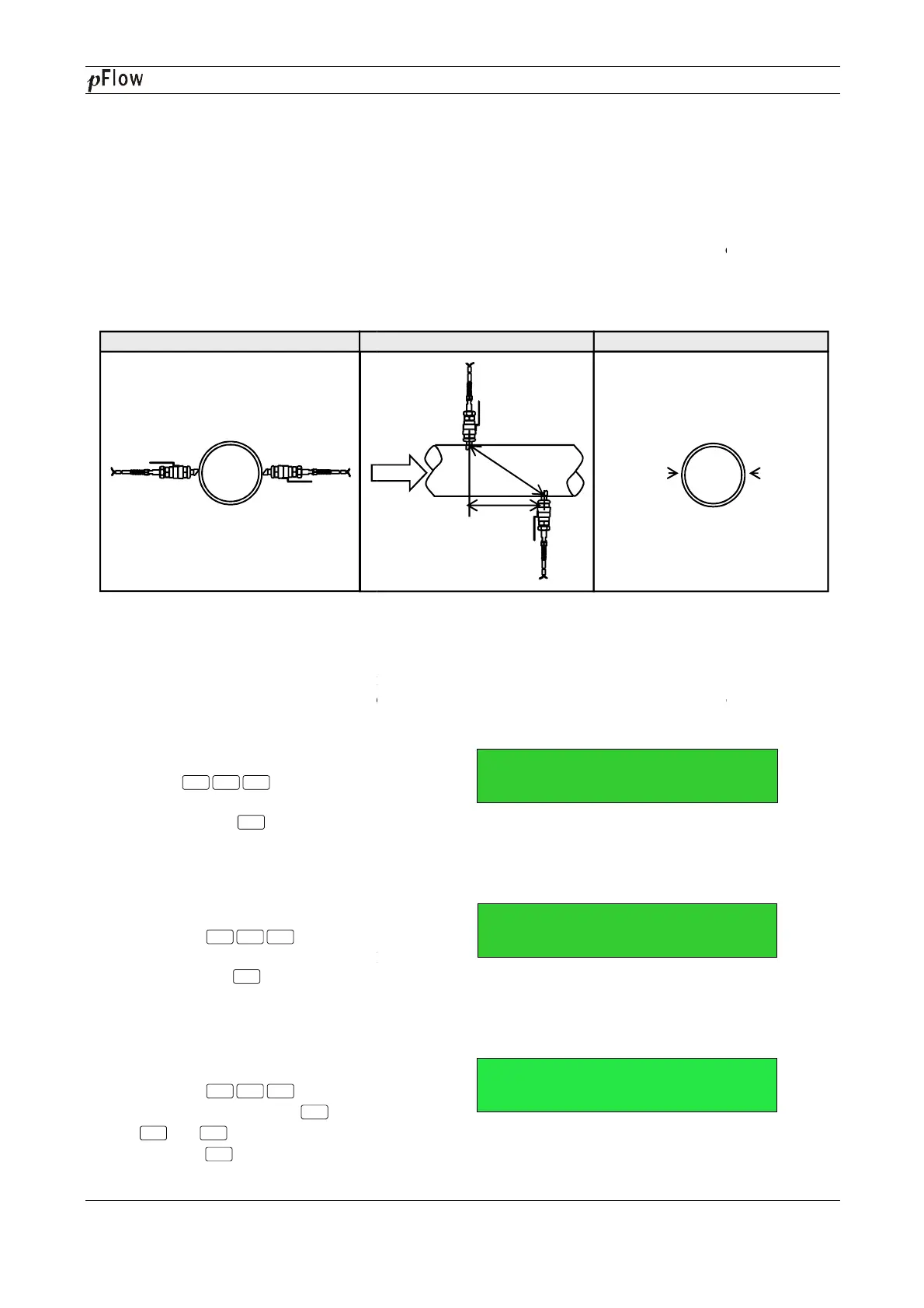

Pipe Parameter Entry Shortcuts

For examp

le, measuring the diameter of DN200, pipe outside diameter is 219mm, pipe wall thickness is 6mm,

pipe inner diameter is 207mm, measuring medium is water, and material is carbon steel, no liner, can be operated

as follows:

Step1. Pipe outside diameter:

Press

M11 and enter the pipe outside diameter, and

then press the key to confirm.

(

For insertion transducer, M11 menu need to be

entered the pipe inner diameter)

Step2. Pipe wall thickness

Press the

window M12, and enter the pipe wall thickness,

and press the key to confirm.

(The Wall Thickness needs to be 0.01mm for

use with insertion sensors.)

Step3. Pipe Material

Press the

window M14, press the key, p

or

key to select Pipe Material, and

press the key to confirm.

Profile Chart

Menu

1 1

Enter

Menu

1

2

Enter

Menu

1

4

Enter

^

^

Enter

D116

Series Ultrasonic Flowmeter

Transducer Mounting Methods

insertion transducer mounting method: Z method through M24, it should be installed according to the

Z method is the most commonly used mounting met

hod for insertion-

type ultrasonic flowmeters, suitable for pipe

00mm. Due to strong signal strength and high measurement accuracy, the Z

method is preferable for pipe sections severely rusted or with too much scale formatio

n on the inside wall. When

installing the transducer using the Z method, be sure that the two transducers and the pipeline center axis are in

clock positions. see below:

Pipe Parameter Entry Shortcuts

le, measuring the diameter of DN200, pipe outside diameter is 219mm, pipe wall thickness is 6mm,

pipe inner diameter is 207mm, measuring medium is water, and material is carbon steel, no liner, can be operated

M11 and enter the pipe outside diameter, and

For insertion transducer, M11 menu need to be

window M12, and enter the pipe wall thickness,

(The Wall Thickness needs to be 0.01mm for

key to select Pipe Material, and

Reference point

At 9 o’clock

Top View

Drill hole spacing

L

Flow

207 mm

0.01 mm

0. Carbon Steel

Series Ultrasonic Flowmeter

Page 49 of 53

insertion transducer mounting method: Z method through M24, it should be installed according to the

type ultrasonic flowmeters, suitable for pipe

00mm. Due to strong signal strength and high measurement accuracy, the Z

n on the inside wall. When

installing the transducer using the Z method, be sure that the two transducers and the pipeline center axis are in

le, measuring the diameter of DN200, pipe outside diameter is 219mm, pipe wall thickness is 6mm,

pipe inner diameter is 207mm, measuring medium is water, and material is carbon steel, no liner, can be operated

Reference point

At 3 o’clock

Loading...

Loading...