Revision: 3.0.3

4.

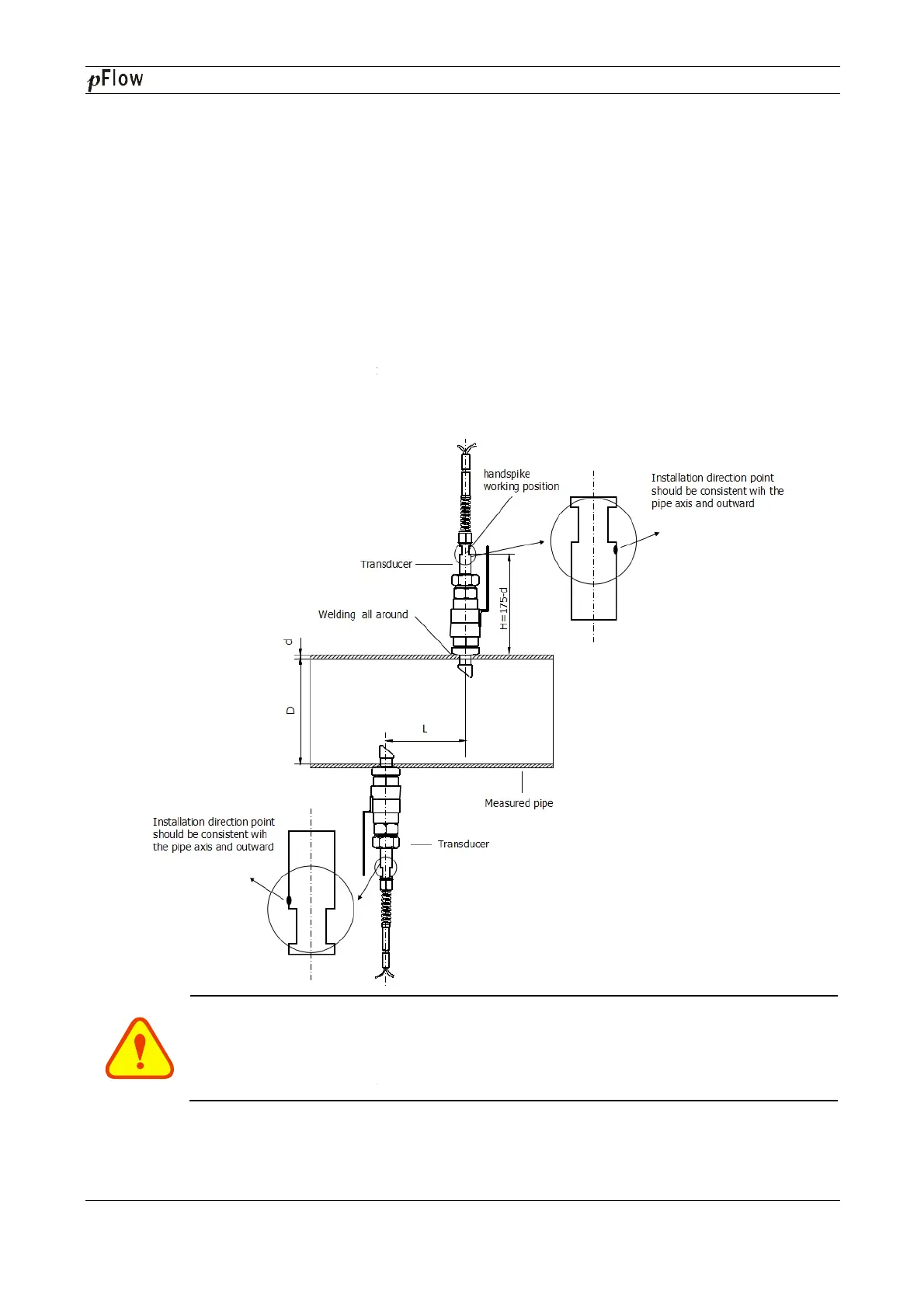

Open the ball valve and insert the transducer, measure the dimension

front end surface of handspike position to meet the following formula:

H=175-d

In this formula:

H is Mounting height (mm);

175 is Transducer length (mm);

d is Pipe wall thickness(mm);

5. Attach the lock ring to the j

oint nut by fitting its pinhole in the locating pin, then tighten the screw slightly

and turn the orientation handle until it points at the middle position between the two transducers and its axes

matches the axes of the pipeline. Finally, tighten the lock

joint nut.

6.

Connect the transducer cables to the corresponding upstream/downstream (upstream=red, downstream=blue)

terminal ends.

7.

Please refer to the following installation diagram:

Important

For

horizontal pipelines, transducers must be fixed on the sides of the pipe (i.e. at the 3 and 9

o’clock position of the pipe) to prevent signal attenuation caused by sediment on the bottom of

the pipe or air bubbles and air pockets in the top of the pipe.

D116

Series Ultrasonic Flowmeter

Open the ball valve and insert the transducer, measure the dimension

from the outer surface of the pipe to the

front end surface of handspike position to meet the following formula:

oint nut by fitting its pinhole in the locating pin, then tighten the screw slightly

and turn the orientation handle until it points at the middle position between the two transducers and its axes

matches the axes of the pipeline. Finally, tighten the lock

ing screw and screw the locating sleeve onto the

Connect the transducer cables to the corresponding upstream/downstream (upstream=red, downstream=blue)

Please refer to the following installation diagram:

horizontal pipelines, transducers must be fixed on the sides of the pipe (i.e. at the 3 and 9

o’clock position of the pipe) to prevent signal attenuation caused by sediment on the bottom of

the pipe or air bubbles and air pockets in the top of the pipe.

Series Ultrasonic Flowmeter

Page 48 of 53

from the outer surface of the pipe to the

oint nut by fitting its pinhole in the locating pin, then tighten the screw slightly

and turn the orientation handle until it points at the middle position between the two transducers and its axes

ing screw and screw the locating sleeve onto the

Connect the transducer cables to the corresponding upstream/downstream (upstream=red, downstream=blue)

horizontal pipelines, transducers must be fixed on the sides of the pipe (i.e. at the 3 and 9

o’clock position of the pipe) to prevent signal attenuation caused by sediment on the bottom of

Loading...

Loading...