Revision: 3.0.3

10 Appendix2-W211

10.1 Overview

W211

type insertion transducers can be installed into metal pipelines via an isolation ball valve (installation into

pipelines of plastic or other materials may require an optional mounting seat). The maximum pipe diameter in

which insertion transducers can be

length (9m standard) normally can be extended to as long as 100m.

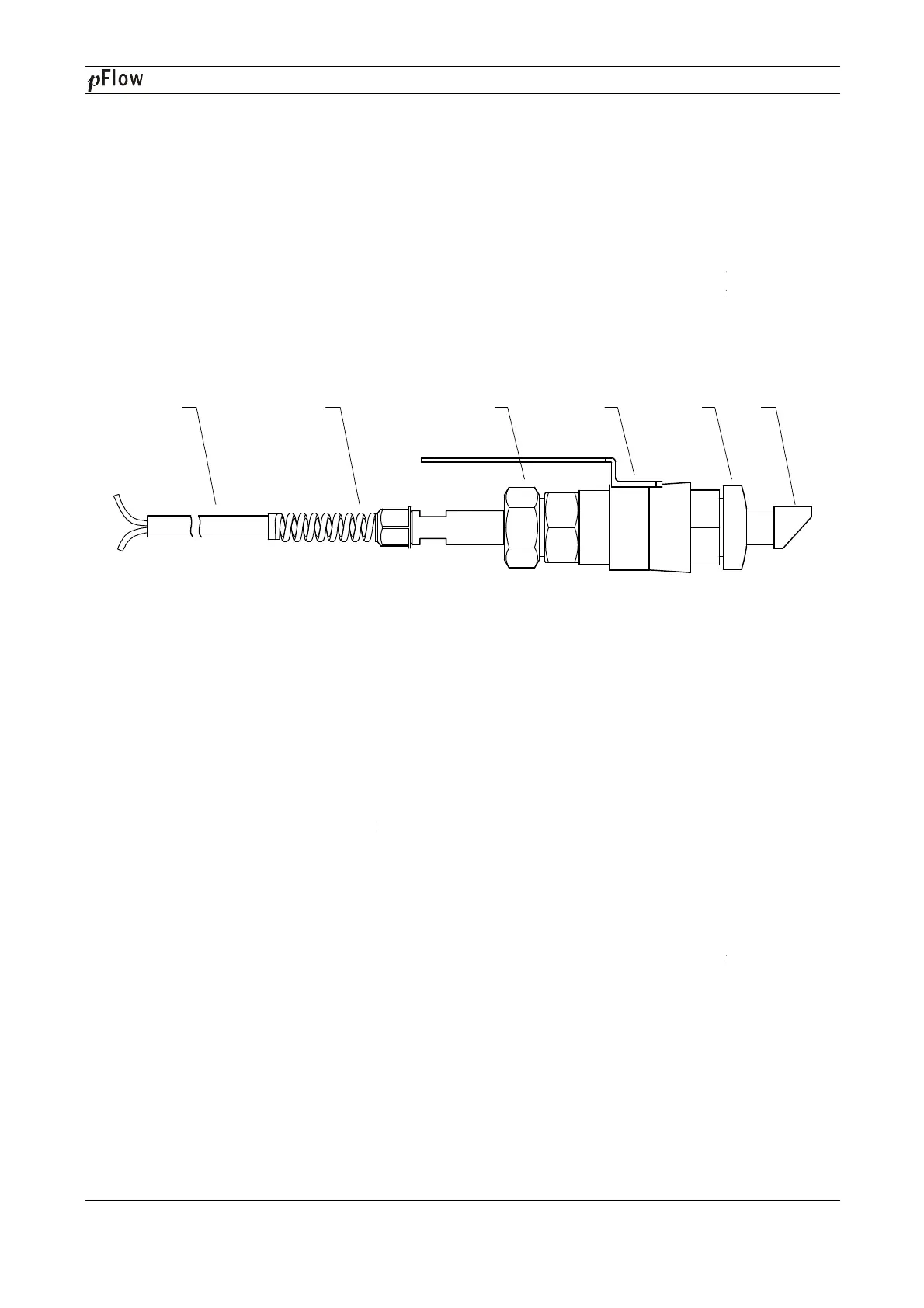

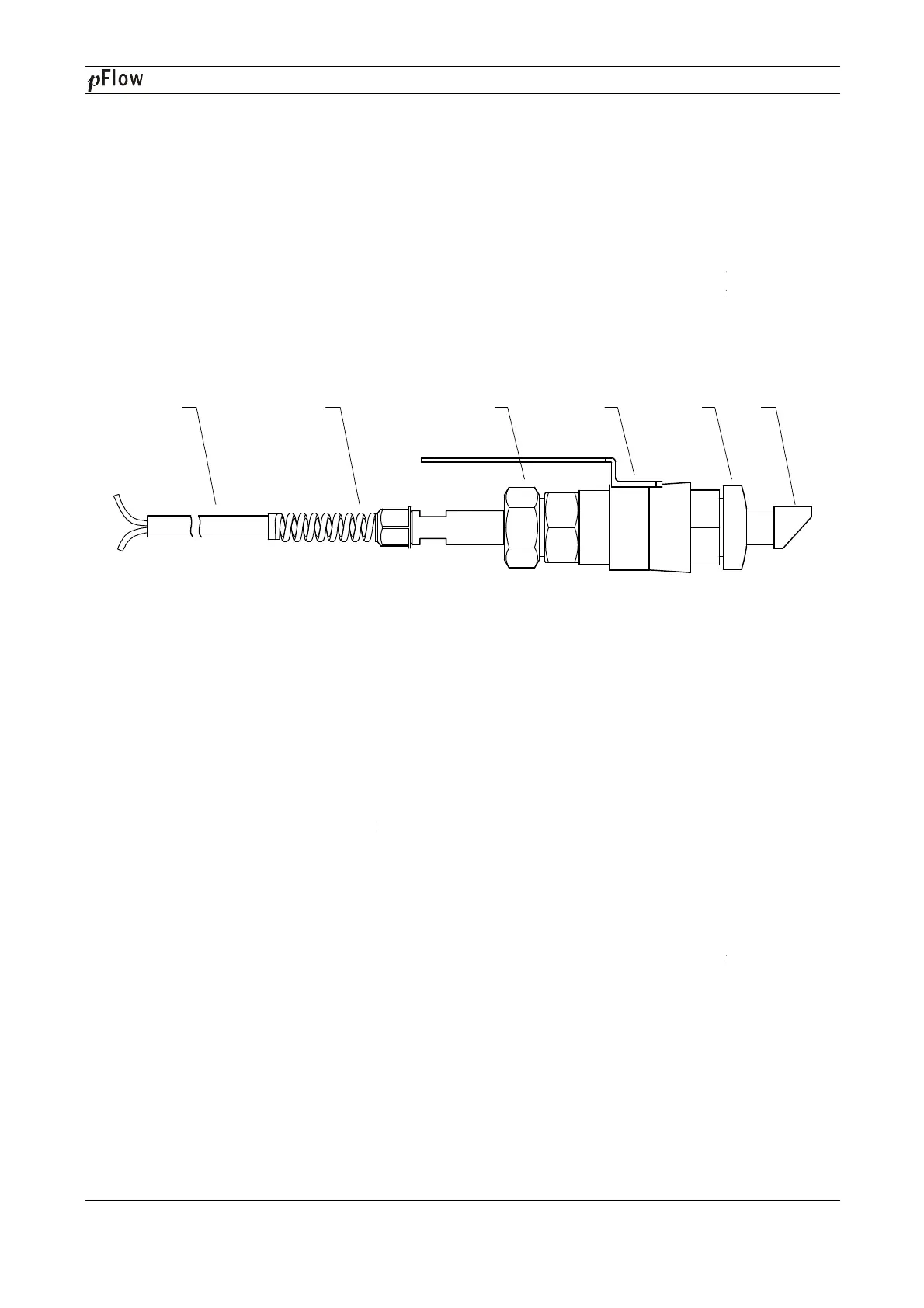

Figure 1 shows a diagram of the W211

Insertion Transducer. The insertion transducer is attached to its mounting

base

(which is welded to the pipe section at the measurement point) via a ball valve. When the transducer is

removed, pipe fluids can be contained by shutting off the ball valve. Therefore, installation and extraction of the

transducer can be performed without

relieving pipeline pressure. An O

safety while installing or operating the transducer.

Construction Drawing of W

1. Cable

2. Connector

10.2

Measurement Point Selection

To guarantee highly accurate measurement results, it is necessary to select an appropriate measurement point

before installing the transducer. For examples of measuring point selection, see the relat

10.3

Determining Transducer Spacing & Transducer Installation

The mounting space of insertion transducer is the center

(please refer to Menu 25). After enter the right parameter, plea

mm)

Mounting method:

1.

Drilling at the measuring point, the diameter of the drilling hole is 24mm. Before drilling, please make the

hole center of transducer mounting base aim at the drilling hole center, and

vertically.

(When the flowmeter need to be hot

interruption,please refer to the Sitelab’

equipment.)

2. Close the ball

valve and screw it tightly on the mounting base.

3.

Twist off the locknut and loose the lock ring, pull the transducer into the joint nut, and then screw up the

joint nut on the ball valve.

1 2

D116

Series Ultrasonic Flowmeter

ransducer

type insertion transducers can be installed into metal pipelines via an isolation ball valve (installation into

pipelines of plastic or other materials may require an optional mounting seat). The maximum pipe diameter in

1200. Fluid temperature range: +10℃~+80oC.

length (9m standard) normally can be extended to as long as 100m.

Insertion Transducer. The insertion transducer is attached to its mounting

(which is welded to the pipe section at the measurement point) via a ball valve. When the transducer is

removed, pipe fluids can be contained by shutting off the ball valve. Therefore, installation and extraction of the

relieving pipeline pressure. An O

-

ring seal and joint nut guarantee user

safety while installing or operating the transducer.

Construction Drawing of W

211 Transducer

3. Locknut

4. Ball value

5.

6. Sensor

Measurement Point Selection

To guarantee highly accurate measurement results, it is necessary to select an appropriate measurement point

before installing the transducer. For examples of measuring point selection, see the relat

ed section in the manual.

Determining Transducer Spacing & Transducer Installation

The mounting space of insertion transducer is the center

-to-

center hole distance between the two transducers

(please refer to Menu 25). After enter the right parameter, plea

se check the mounting space in Menu 25. (unit:

Drilling at the measuring point, the diameter of the drilling hole is 24mm. Before drilling, please make the

hole center of transducer mounting base aim at the drilling hole center, and

(When the flowmeter need to be hot

-

tapped into the pipe under pressure without flow

operation construction of DDK electric Hot-

valve and screw it tightly on the mounting base.

Twist off the locknut and loose the lock ring, pull the transducer into the joint nut, and then screw up the

3 4 5

Series Ultrasonic Flowmeter

Page 47 of 53

type insertion transducers can be installed into metal pipelines via an isolation ball valve (installation into

pipelines of plastic or other materials may require an optional mounting seat). The maximum pipe diameter in

Insertion Transducer. The insertion transducer is attached to its mounting

(which is welded to the pipe section at the measurement point) via a ball valve. When the transducer is

removed, pipe fluids can be contained by shutting off the ball valve. Therefore, installation and extraction of the

ring seal and joint nut guarantee user

To guarantee highly accurate measurement results, it is necessary to select an appropriate measurement point

ed section in the manual.

center hole distance between the two transducers

se check the mounting space in Menu 25. (unit:

Drilling at the measuring point, the diameter of the drilling hole is 24mm. Before drilling, please make the

tapped into the pipe under pressure without flow

Twist off the locknut and loose the lock ring, pull the transducer into the joint nut, and then screw up the

6

Loading...

Loading...