2 | Section 11 15705-011 | Rev | 2022-03-01 | e-mail csd@pow.com

Section 11 | SEW Eurodrive Motor

Maintenance and Troubleshooting

www.pflow.com

P 414 352 9000

F 414 352 9002

6720 N. Teutonia Ave.

Milwaukee, WI 53209

Brake Running

Operation

Brake

Maintenance

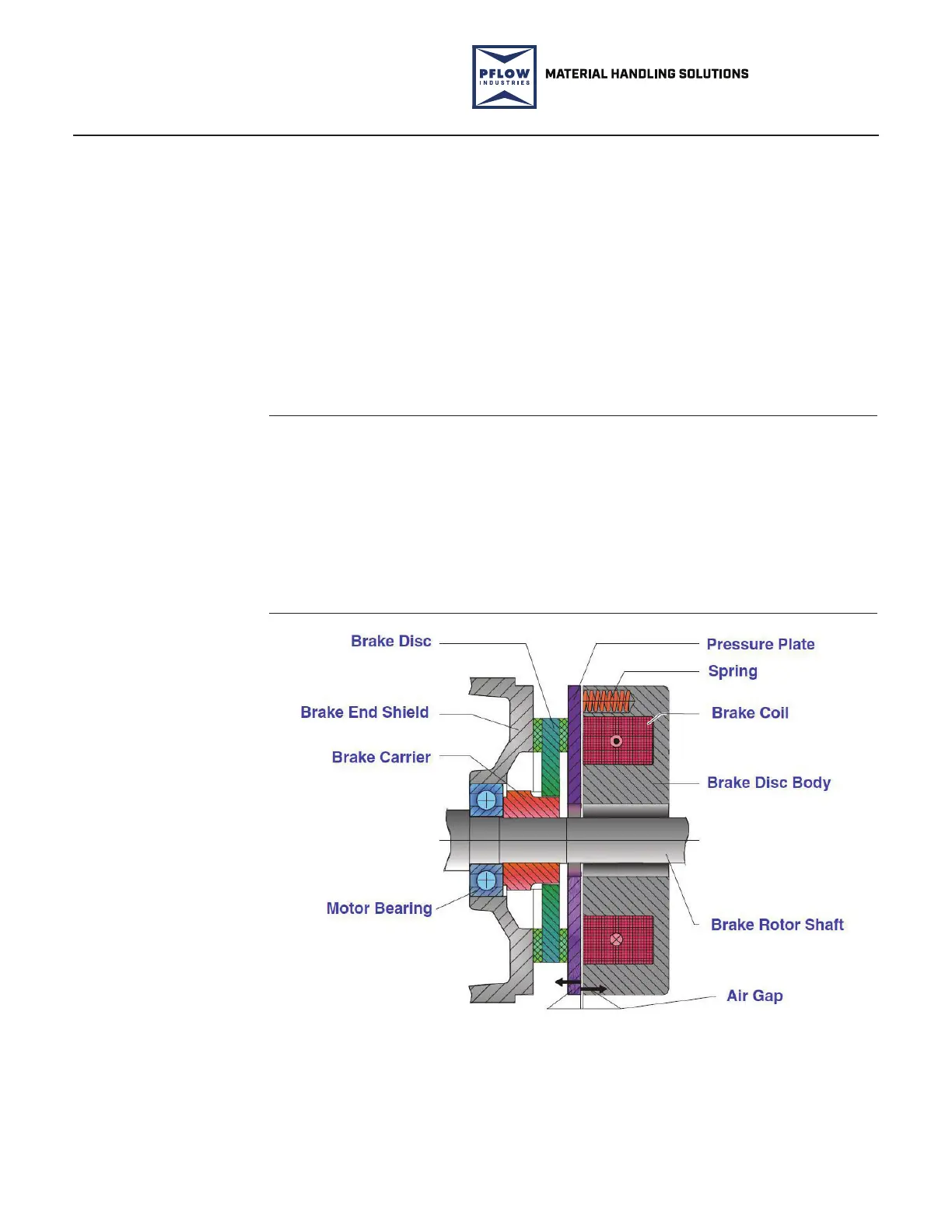

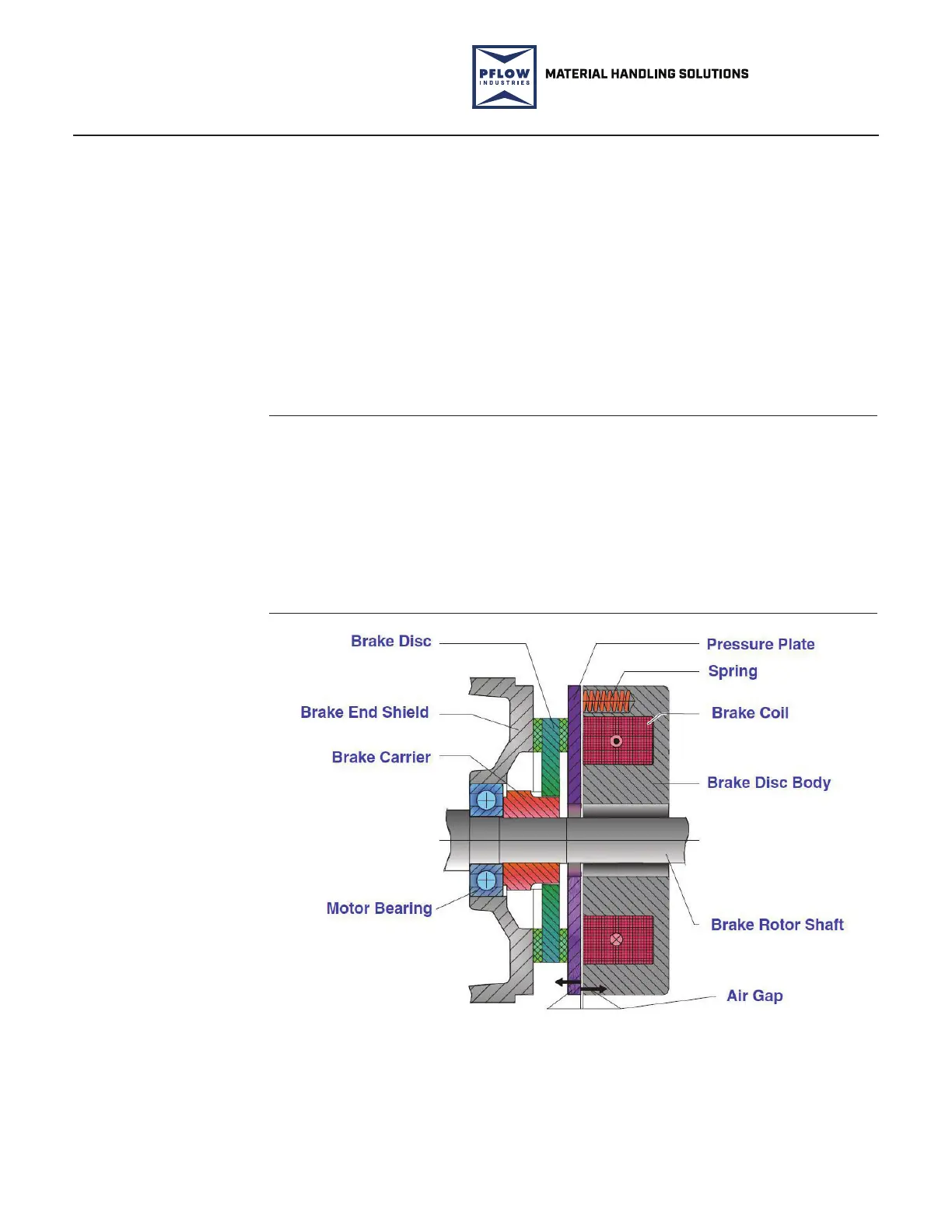

Without any malfunctions occurring, the running operation does not require

any maintenance except for a visual inspection of the brake disc lining, visual

inspection of the pressure plates, and verifying the size of the air gap. See

Figure 11-1. The air gap increases as the lining on the rotor wears. When the

maximum air gap is reached, an adjustment of the air gap is required for the

safe operation of the brake. The functional capability and safety function of the

brake will be compromised as additional wear occurs and must be replaced.

Inspections must be veried in accordance with the following schedule.

Inspection intervals:

Holding brake: At least every six months

Use shorter intervals in case of frequent emergency stops

1. Remove cover.

2. Slide the rubber seal to the side to expose the stationary disc and brass shim.

3. Visually inspect the brake disc for damage.

4. Visually inspect the pressure plates for discoloration.

5. Measure the air gap with a feeler gauge at

three dierent positions around

the brake

between the stationary disc and the coil. [See the next page for

the appropriate measurement or conrm current information with SEW

Eurodrive by calling 1-888-SEW-3876 and reference your serial number.]

Air Gap Location

Figure 11-1

Loading...

Loading...