15705-011 | Rev | 2022-03-01 | e-mail csd@pow.com Section 11 |

Section 11 | SEW Eurodrive Motor

Maintenance and Troubleshooting

www.pflow.com

P 414 352 9000

F 414 352 9002

6720 N. Teutonia Ave.

Milwaukee, WI 53209

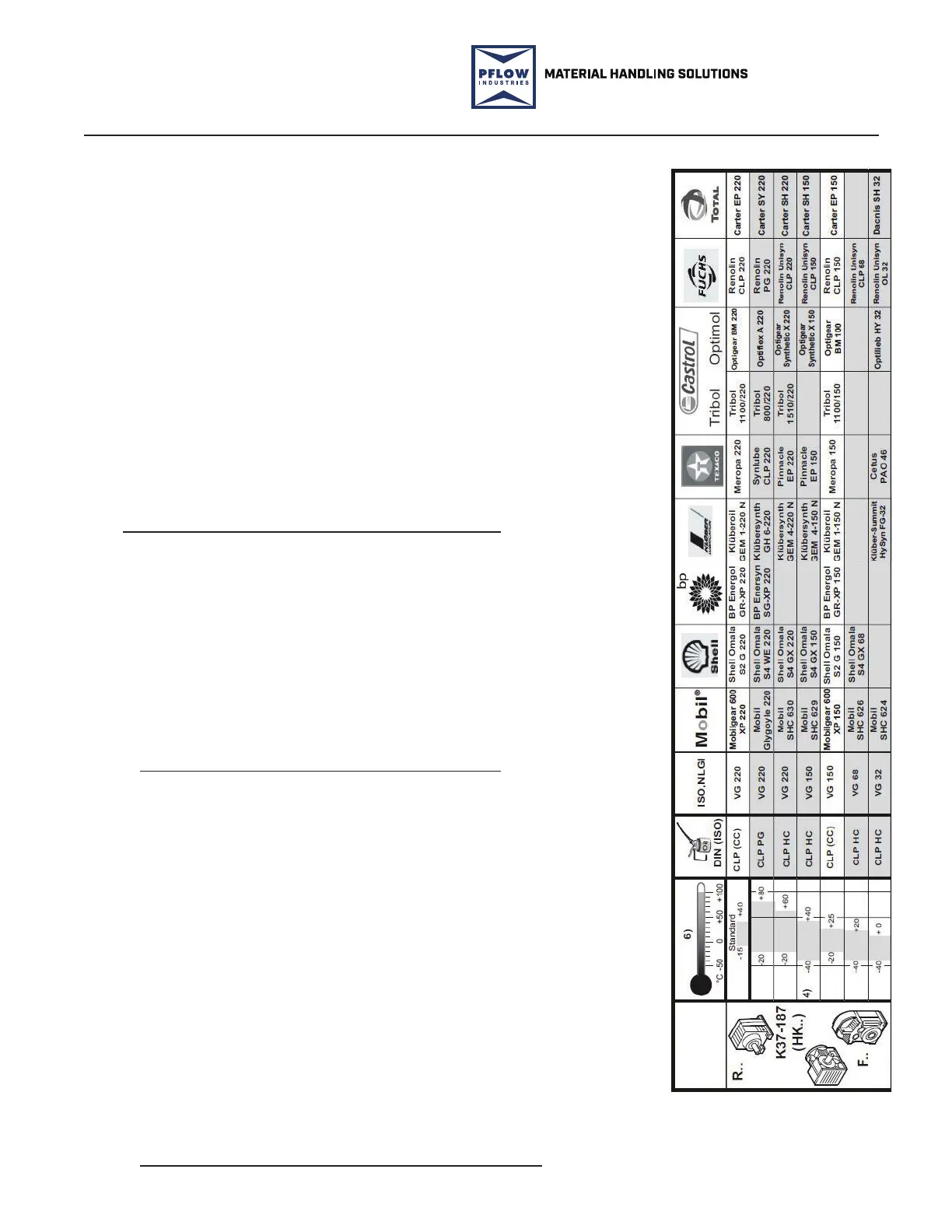

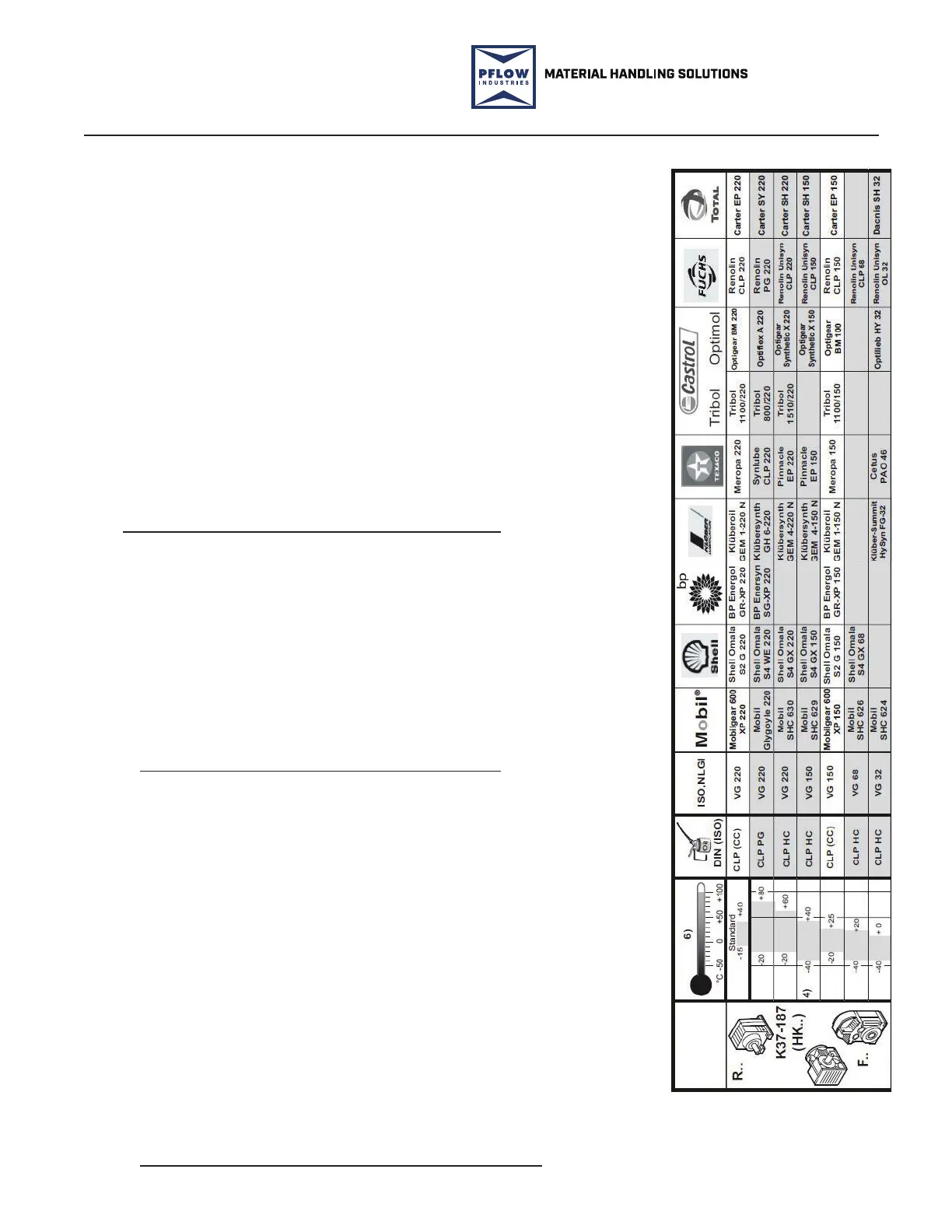

Lubrication Notes Lubricant

Table

z Food-grade lubricants must be in

compliance with FDA 212 CFR 178.3570

and qualify as an NSF-H1 lubricant. Please

consult with lubrication manufacturer for

more information.

z When making a lubrication change, verify

with the lubrication supplier to assure

compatibility and to obtain recommended

cleaning or ushing procedures.

z Make sure not to mix dierent oils with

dierent additive packages or dierent

base oil formulation types. Polyglycol (PG)

oils are not capable of being mixed with

other oil types and should never be mixed

with mineral oil or polyalphaolen (PAO)

synthetic oil.

Oil Volume

Changing the Oil

Gear units are shipped from the factory

with a pre-determined oil ll level in

accordance to the specied reducer size

and mounting position.

Actual oil volume can vary slightly depending

upon the gear case size, mounting, and ratio.

Prior to starting the reducer, check the oil

ll level using the reducer’s oil level plug and

drain or add oil as needed.

1. Determine the position of the oil level plug and

the breather valve. Refer to the next page.

2. Place a container under the oil drain plug.

3. Slowly remove the oil level plug. Small amounts

of oil may leak out if the permitted maximum

oil level is higher than the lower edge of the oil

level bore.

4. Remove the breather valve and the oil drain plug.

5. Drain the oil completely.

6. Re-insert the oil drain plug.

7. Fill with fresh oil of the same type via the

breather bore. Do not mix dierent synthetic

lubricants. Observe the oil quantity according to

the specications on the nameplate.

8. Re-insert the oil level plug and the breather valve.

Loading...

Loading...