41 | P a g e

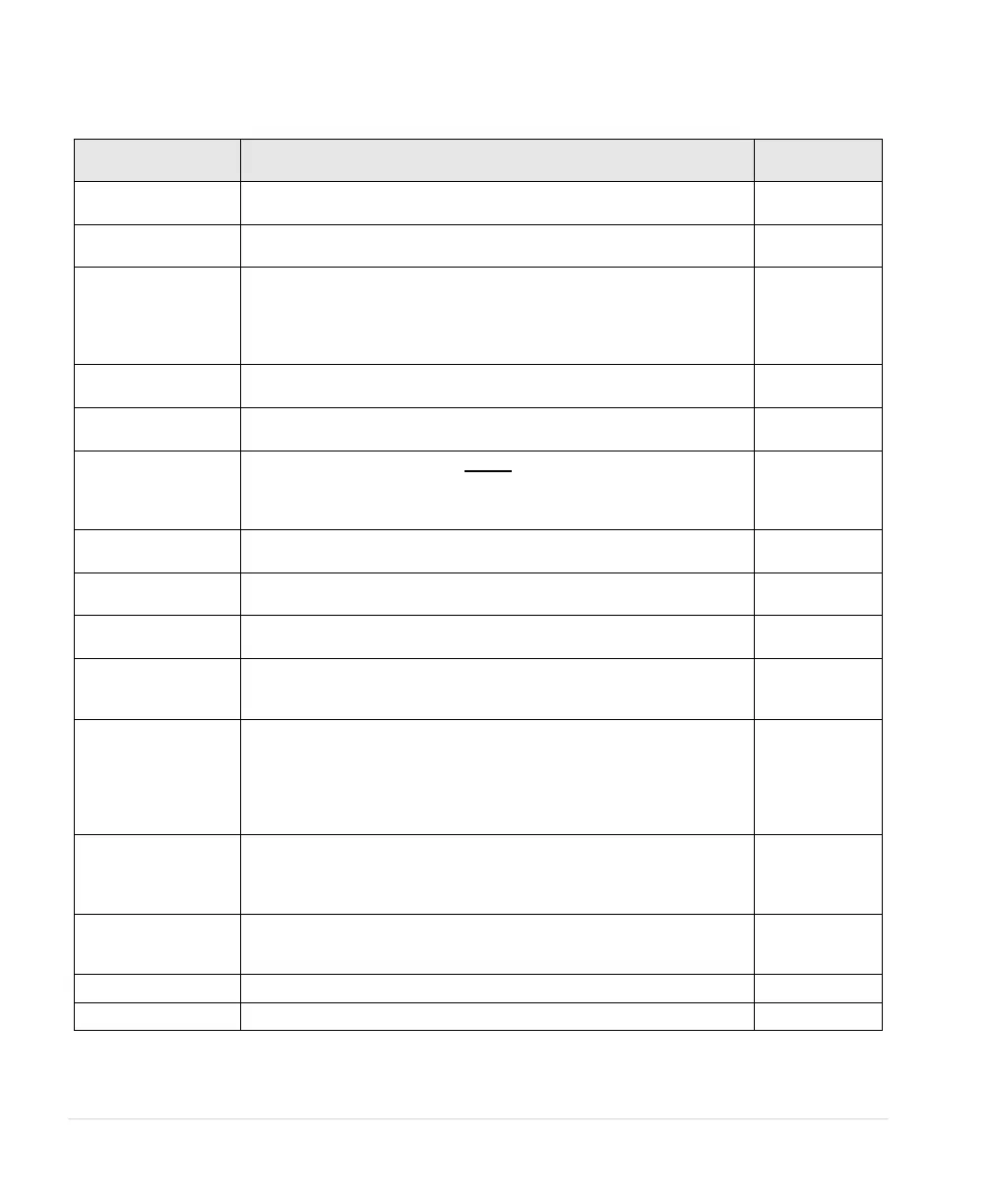

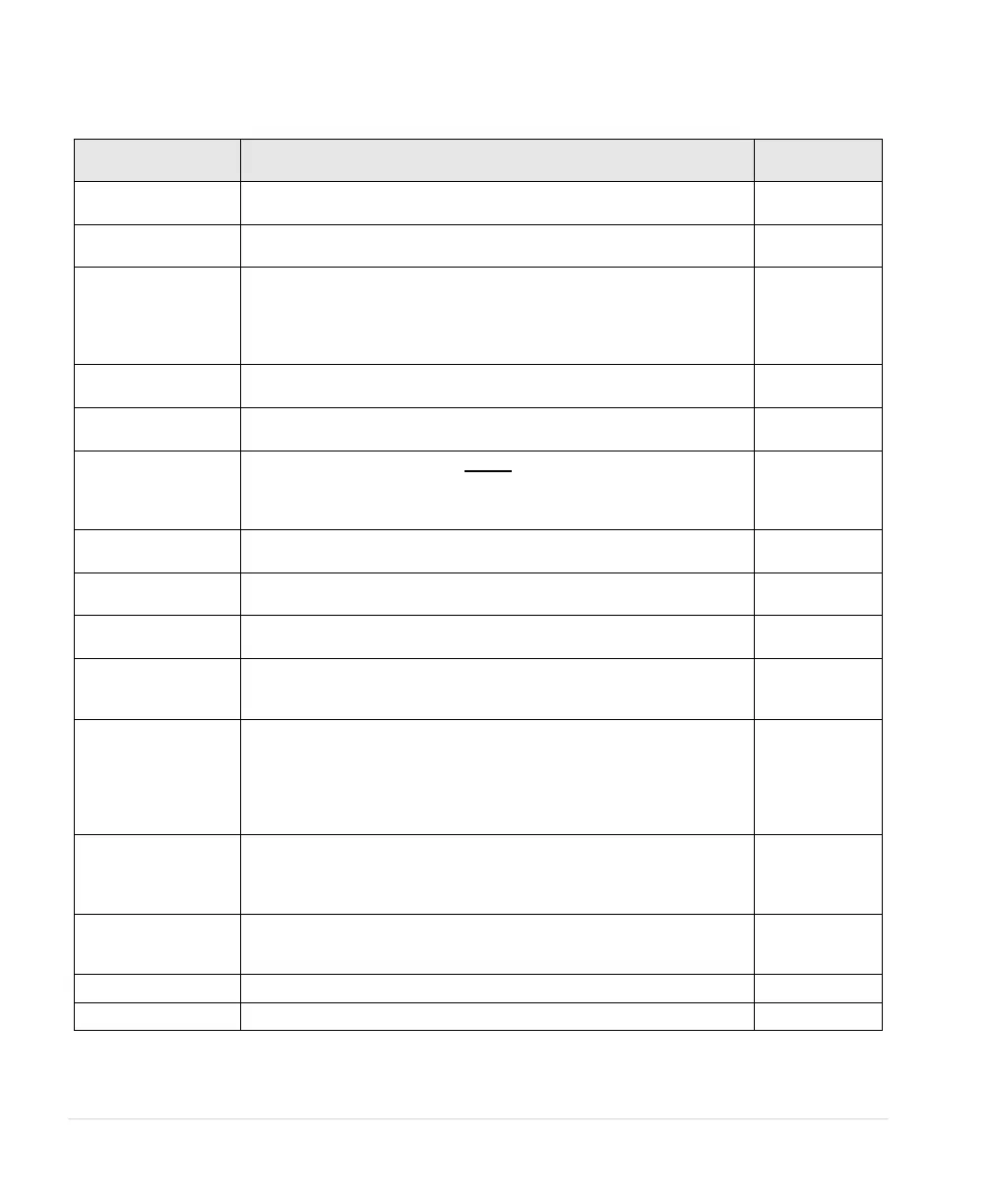

Table 15 - Constant Pressure Parameters

psi at which unit will determine there is a broken pipe. Value of zero

disables this feature.

In minutes. Time at which measured pressure is below BROKEN PIPE

PSI, unit will fault out.

In seconds. Used to prevent short cycling in CP systems. If the motor

was off during the last cycle for a period greater than TOFF, the

minimum on time of the motor is T1ON. If the motor was off for a period

less than TOFF, the minimum on time of the motor is T2ON. Default

values give a minimum cycle time of about 1 minute.

In seconds. See T OFF above. T1ON should be set to be less than

T2ON.

In seconds. See T OFF above. T1ON should be set to be less than

T2ON.

As Hz. This parameter value is added to the frequency set by the

parameter MINIMUM FREQ. The combined value is the frequency at

which drive will enter sleep mode when pressure is controlled at the set

point.

As psi. The parameter value specifies a pressure increase in psi before

sleep mode. The value is added to psi SETPOINT.

In Hz. Sets the maximum frequency applied to the motor during the pre-

charge interval.

In minutes. Sets the maximum time for pre-charge regardless of any

sensor inputs. A setting of zero disables the pre-charge mode.

Used only for analog CP systems. Pre-charge will be terminated when

pressure reaches this set point. Should be set less than psi

SETPOINT.

Multiplier for the analog error signal in an analog constant pressure

system. When parameter is set to a value of zero the keypad displays

SIMPLE MODE and the controller switches to an algorithm which does

not require a gain setting. See Section 7.8, Troubleshooting Constant

Pressure Systems, for details. When using PI control, best results will

be obtained by starting with a value of 5 for PROPORTIONAL GAIN.

Multiplier for the integral term in PI control of analog constant pressure.

Used to fine tune control of unstable systems. Parameter is disabled

when PROPORTIONAL GAIN is set to SIMPLE MODE. See Section

7.8, Troubleshooting Constant Pressure Systems, for details.

Used to reduce overshoot and oscillation. Should be used only when

necessary because it tends to amplify noise in the transducer signal. It

may cause the system to become unstable.

Controls the rate of frequency increase in response to the error term.

Sample interval for the PID Filter Gain.

Loading...

Loading...