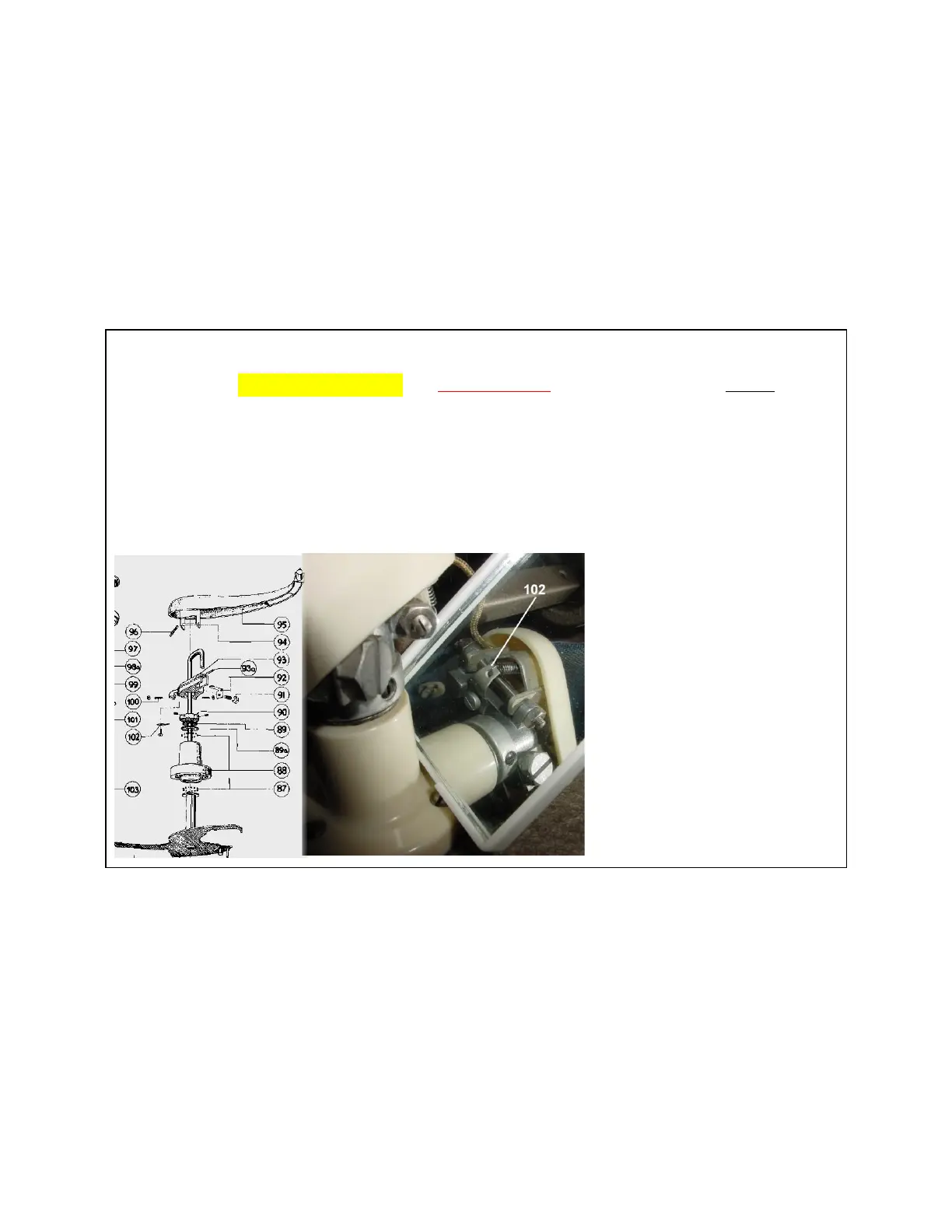

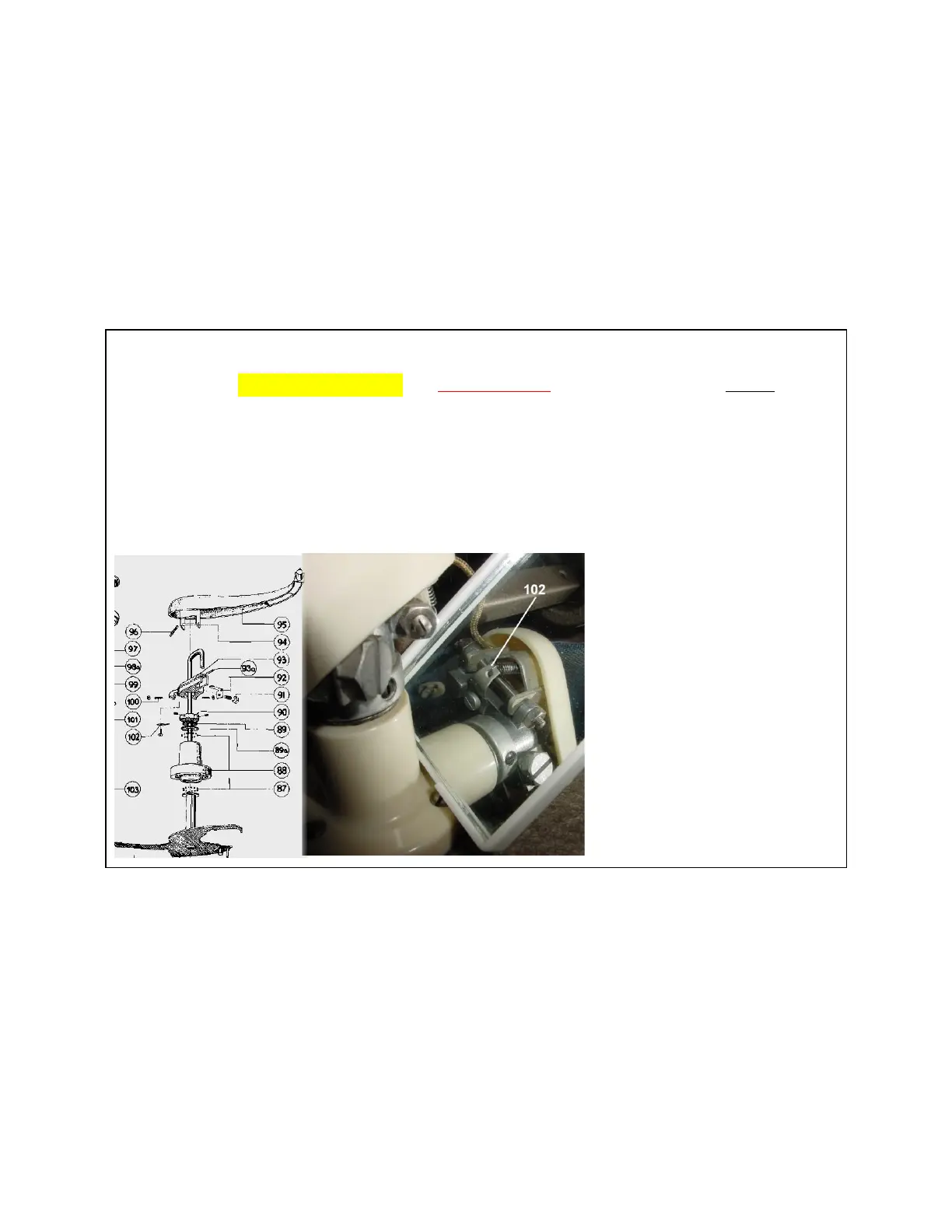

H. To set the height of 17.5 cm (7 ") plates, first push the slide diameter and the repeat button, the

needle tip should now be placed on the 17.5 (7") run-in groove. Correction is possible by bending the

steel wire spring (113) in the curved part of this spring.

P16b

I. With the aid of a spring pressure gauge, the needle pressure can now be adjusted by bending the

spring clip (fig 8 102). The needle pressure must be approx. 12.5 grams. With the weight now set, the

switch (P.U. support) must be pushed down completely. Possibly the weight may be increased to 13

gram. The gald pressure is measured in case there is only one plate on the turntable. The caliper/bracket

with roller (16) must be set so that the switch is switched off when the P.U.arm is on the

role rest. The roller must turn smoothly.

J. To find out if the arm rotates easily, the

next test. Hold the sensor arm horizontally and place the needle tip on a flat mirror. Move the mirror

back and forth in the horizontal plane. This should be so light that the

needle does not move on the mirror.

K. The wire spring (93a) must press lightly against the lift rod.

This keeps the vertical movement of the P.U. arm constant.

38

Loading...

Loading...