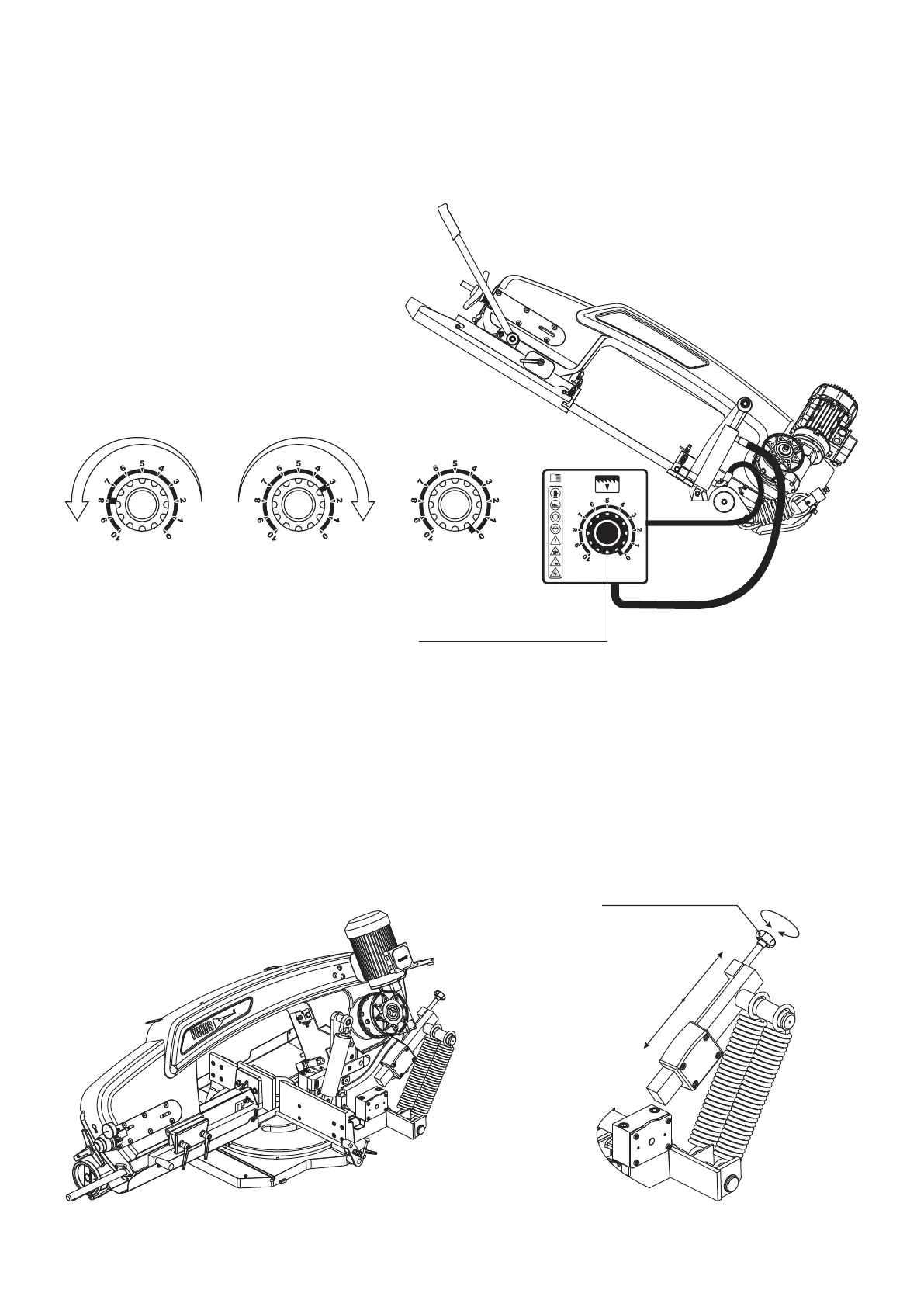

4.2. Oil Damper - Saw Blade Feed to the Cut

The oil damper relief valve allows for a continuous setting of the velocity of saw blade feed towards the cut or stabilizing the saw arm

in any position by mechanical closing. The optimum value of descent can be determined very easily by ear. The saw blade movement

must be noiseless, free from vibrations. Such a state can be achieved by reducing or increasing the pressure force (by the velocity of

saw arm descent). The prerequisite of setting the optimum pressure is selecting the correct saw blade velocity and the optimum size

of the saw blade teeth.

ACCELERATION

SAW ARM

DESCENT

DECELERATION

SAW ARM DESCENT

STOP

SAW ARM DESCENT

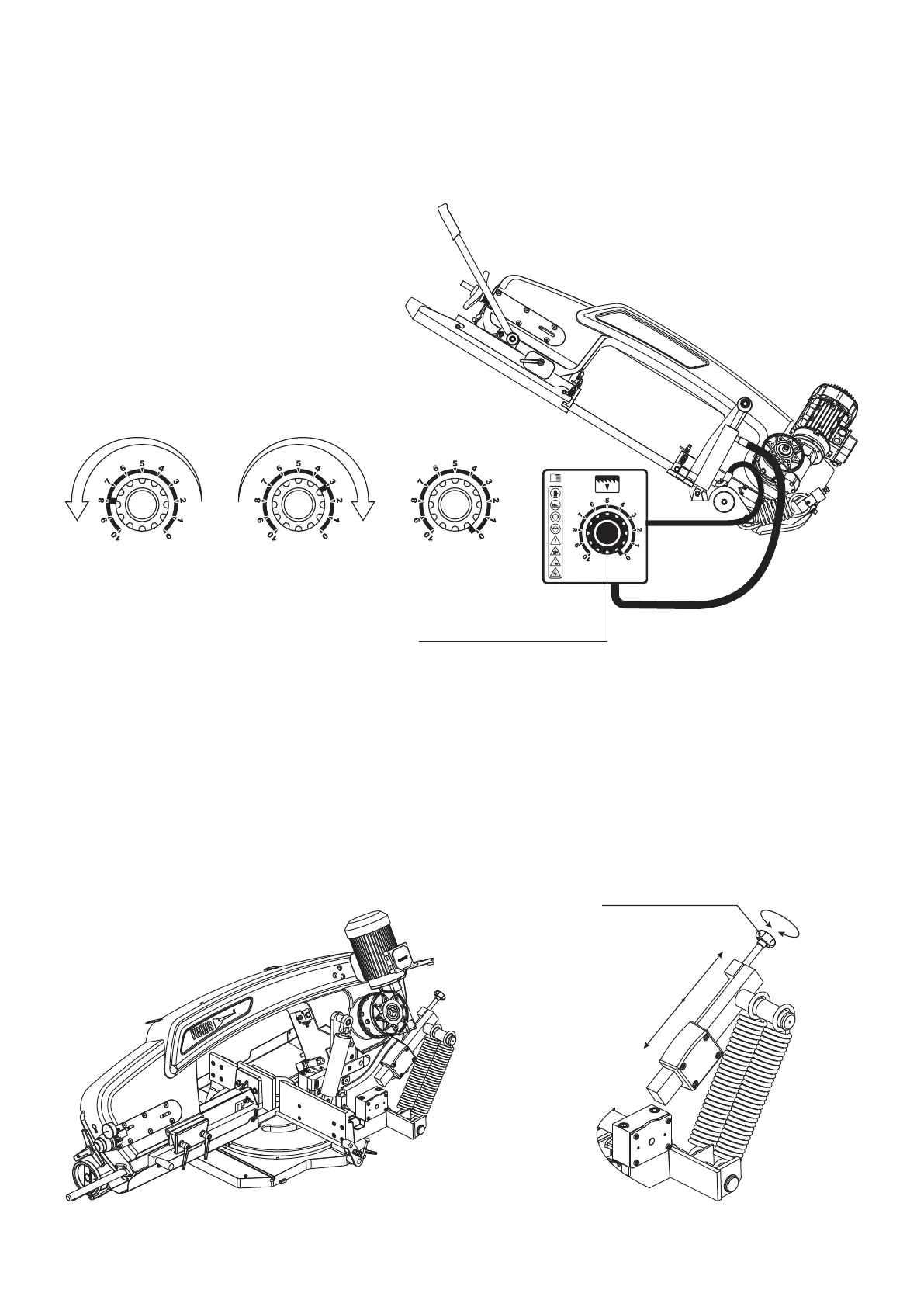

4.3. Mechanical Control of the Feed

The springs are pre-tensioned during the manufacture for a universal use, during which the arm smoothly rises and descends with a

force ration ideal for most applications. Especially when cutting sturdy full materials, it is useful to increase the blade feed using the

weight of the cast iron arm. This is facilitated by continuous loosening of the adjusting screw and pulling down of the springs. If cutting

only thin-walled sectional construction materials, it is, on the contrary, possible to pull up the springs by screwing-in the adjusting

screw, which leads to a smaller blade feed to the cut and, in particular, easier arm uplift. The adjusting screw moves easily in the

position, in which the arm is raised and the springs are not tensioned.

ADJUSTING SCREW

OIL DAMPER RELIEF VALVE

Loading...

Loading...