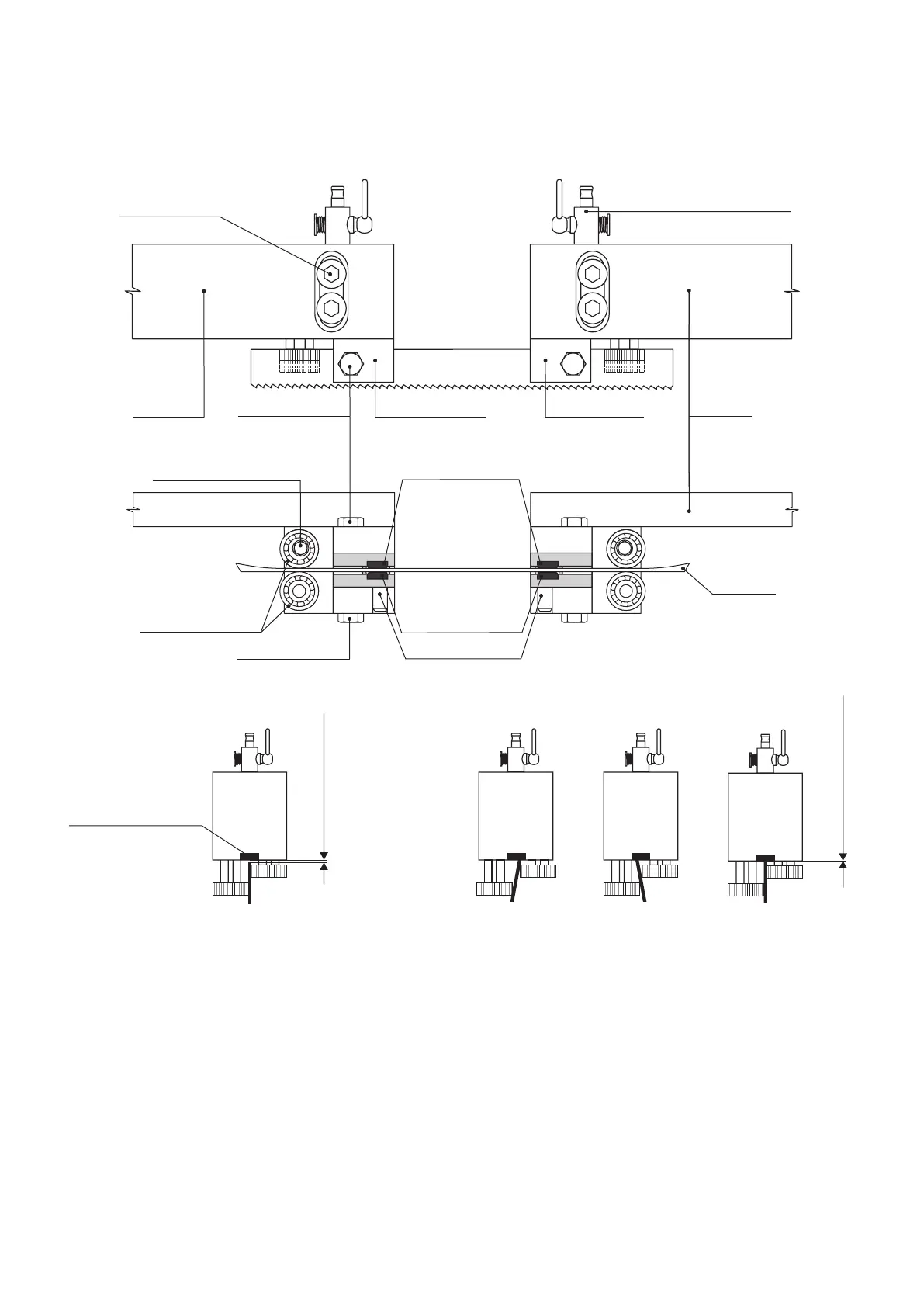

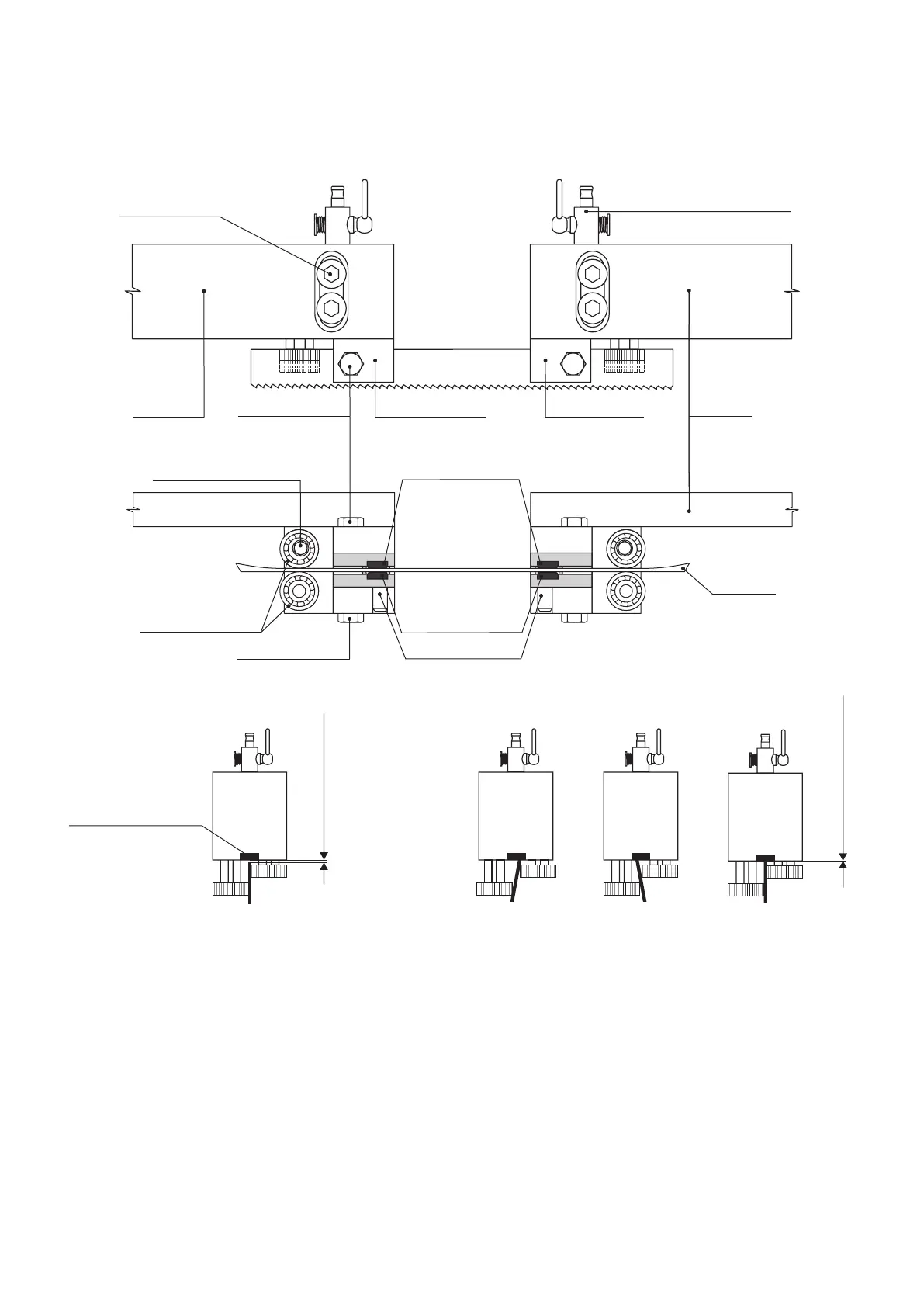

Guide Head Setting Procedure

Switch off the MAIN SWITCH or disconnect the machine from the mains and secure it against restarting. Close the oil damper relief

valve (see Section 4.2.) and raise the arm to about 20 mm above the fixed jaw of the vice. Set the movable guide head, so that the

distance between the guide heads is approximately 20 cm. Disconnect the inlet hoses from the coolant valve. Remove the protective

covers of the saw blade and open/remove the back cover of the arm (see section 4.6.), if necessary lift the arm about 20 mm above the

fix camping jaw again. Loosen the tensioning star, take the saw blade off the wheels and push it off the guide heads. Unscrew the guide

heads gradually from the fixed and movable bars, turn them by 180 ° (with bearings and hardened steel blade guides facing upwards)

and screw back to the bars. Make sure that the guide heads are perpendicular to the guide bars and that the height of the guide heads

is identical. If you find special washers between the guide head and the bar, make sure you place them back afterwards. Check the

tightening of the fixed hardened steel blade guides. Insert approximately 30 cm of an old saw blade in the guide heads between the

hardened steel blade guides and the bearings. Set the hardened steel blade guides using the width adjusting screw, so that the saw

blade does moves between the guides without any play and jamming. When the saw blade has been adjusted, set the eccentrically

mounted bearings in such a manner that the bearings do not “cut” the saw blade, but at the same time you have to prevent too much

space for the saw blade between the bearings. When the saw blade moves, the bearings are carried along by the saw blade. Make

sure that all bolt connections are tight. Unscrew the guide heads from the bars. Fit the saw blade on the wheels, check its correct

alignment on the wheels and tension the saw blade. Install both guide heads on the saw blade in the space between the bars and

adjust them in the correct position on the bars. Distinguish the correct height setting of the guide heads based on the machine type.

ECCENTRIC BEARING SCREW

HARDENED STEEL

BLADE GUIDES WIDTH

ADJUSTING SCREW

ECCENTRICALLY

ARRANGED BEARINGS

HARDENED STEEL

BLADE GUIDE SCREW

MOVABLE HARDENED

STEEL BLADE GUIDES

FIXED HARDENED

STEEL BLADE GUIDES

MOVABLE

GUIDE BAR

FIXED

GUIDE BAR

MOVING GUIDE HEAD

GUIDE HEAD SCREW

SAW BLADE

Incorrect saw blade guidance

Correct saw blade guidance

to center between guide bearings

UPPER HARDENED

STEEL BLADE GUIDES

Approximately 0,5-1 mm

WARNING!

There has to be a clearance

COOLANT VALVE

FIXED GUIDE HEAD

HARDENED STEEL

BLADE GUIDE SCREW

4.8. Guide Heads Adjustment

The correct setting of the bearings and the hardened steel blade guides in the guide heads substantially influences the saw

blade life and the quality of the cut. The eccentrically arranged guide head bearings must be set in such a manner that the saw

blade surface is parallel to the surface of hardened steel blade guides with a minimum play (clearance) between the plates and the

blade.

Loading...

Loading...