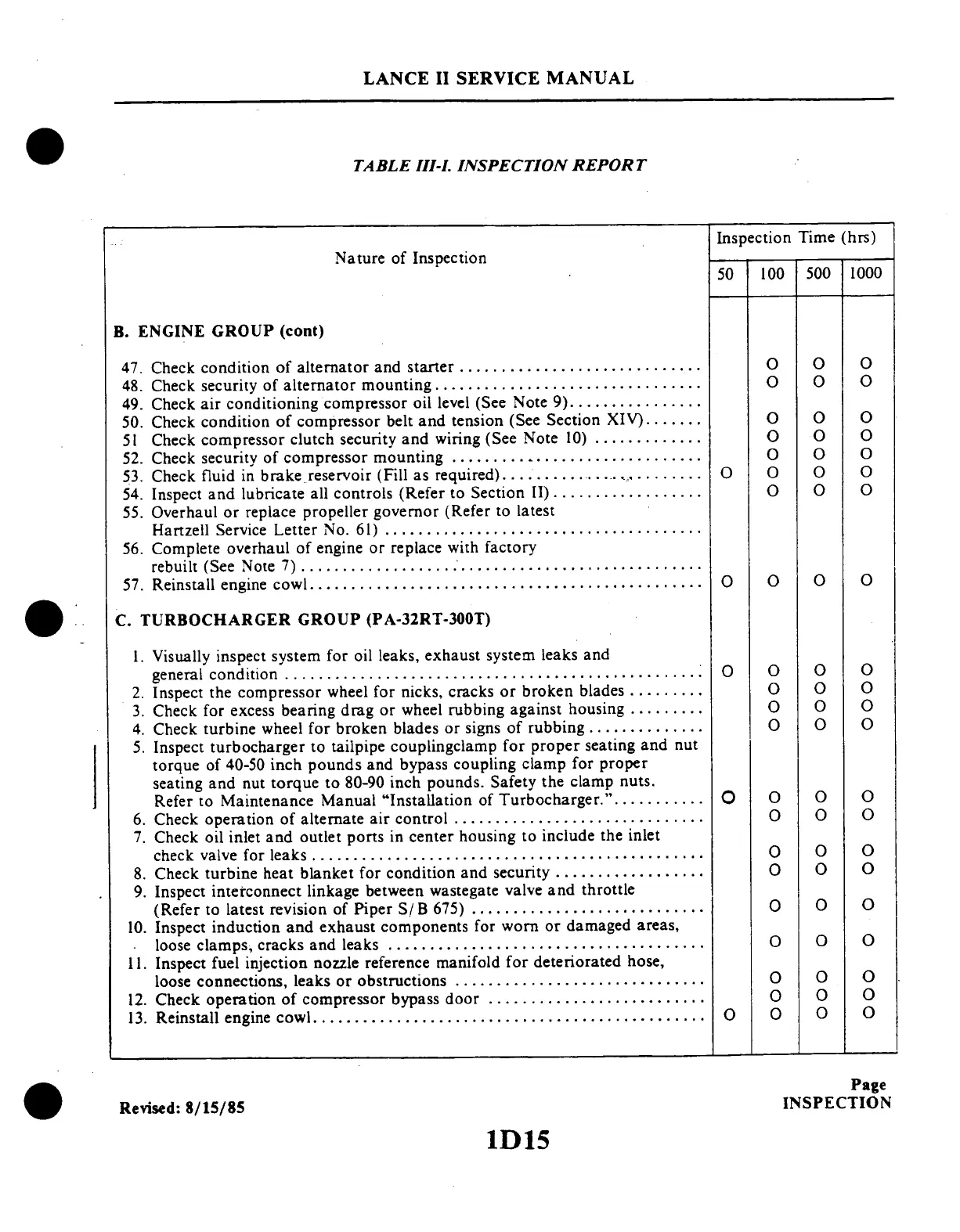

LANCE

II

SERVICE

MANUAL

TABLE

III-I.

INSPECTION

REPORT

Inspection

Time

(hrs)

Nature

of

Inspection

50

100

500

1000

B.

ENGINE

GROUP

(cont)

47.

Check

condition

of alternator

and

starter

.............................

48. Check

security

of alternator

mounting

...............................

49.

Check

air

conditioning

compressor

oil

level

(See

Note

9)................

50.

Check

condition

of compressor

belt

and

tension

(See

Section

XIV).......

51

Check

compressor

clutch

security

and

wiring

(See

Note

10)

.............

52.

Check

security

of compressor

mounting

..............................

53.

Check

fluid

in

brake

reservoir

(Fill

as

required)

........................

54.

Inspect

and

lubricate

all

controls

(Refer

to

Section

II) ..................

55.

Overhaul

or replace

propeller

governor

(Refer

to

latest

Hartzell

Service

Letter

No.

61)......................................

56.

Complete

overhaul

of

engine

or

replace

with

factory

rebuilt

(See

Note

7)

................................................

57.

Reinstall

engine

cowl

...............................................

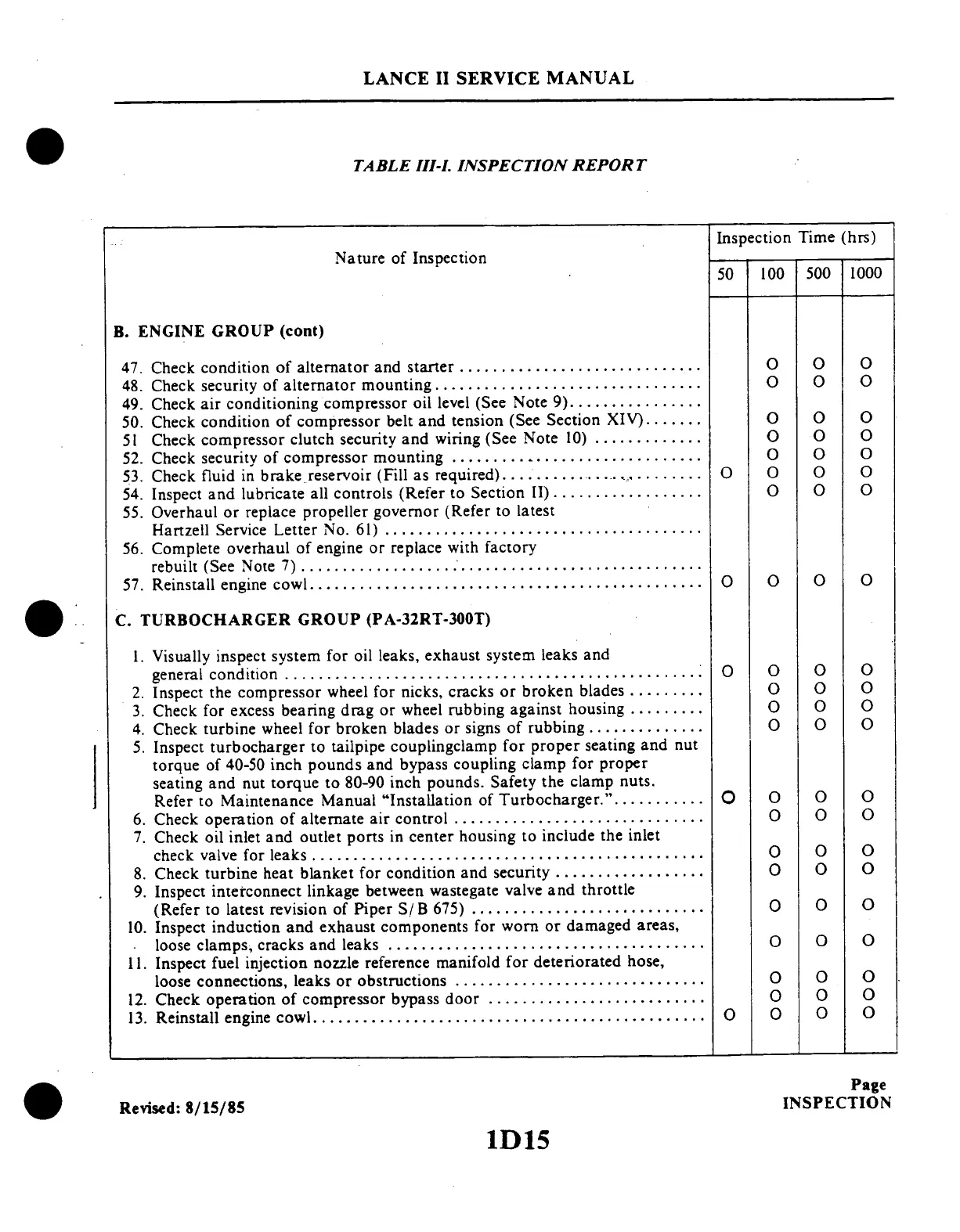

C.

TURBOCHARGER

GROUP

(PA-32RT-300T)

1. Visually

inspect

system

for

oil

leaks,

exhaust

system

leaks

and

general

condition

.................................................

2.

Inspect

the

compressor

wheel

for

nicks,

cracks

or

broken

blades

.........

3. Check

for

excess

bearing

drag

or

wheel

rubbing

against

housing

.........

4.

Check

turbine

wheel

for

broken

blades

or signs

of rubbing

..............

5. Inspect

turbocharger

to

tailpipe

couplingclamp

for

proper

seating

and

nut

torque

of

40-50

inch

pounds

and

bypass

coupling

clamp

for

proper

seating

and

nut

torque

to 80-90

inch

pounds.

Safety

the

clamp

nuts.

Refer

to

Maintenance

Manual

"Installation

of Turbocharger."..........

6. Check

operation

of alternate

air control

..............................

7.

Check

oil

inlet

and

outlet

ports

in

center

housing

to include

the

inlet

check

valve

for

leaks

...............................................

8.

Check

turbine

heat

blanket

for

condition

and

security

..................

9.

Inspect

interconnect

linkage

between

wastegate

valve

and

throttle

(Refer

to

latest

revision

of

Piper

S/ B

675)

............................

10.

Inspect

induction

and

exhaust

components

for

worn

or

damaged

areas,

loose

clamps,

cracks

and

leaks

......................................

11.

Inspect

fuel

injection

nozzle

reference

manifold

for

deteriorated

hose,

loose

connections,

leaks

or

obstructions

..............................

12.

Check

operation

of

compressor

bypass

door

..........................

13.

Reinstall

engine

cowl

...............................................

O

0

0

O

0

0

0

0

0

0

0

O

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

O

0

0

0

0

0

0

0

0

Page

Revised:

8/15/85

INSPECTION

1D15

Loading...

Loading...