LANCE II SERVICE MANUAL

810

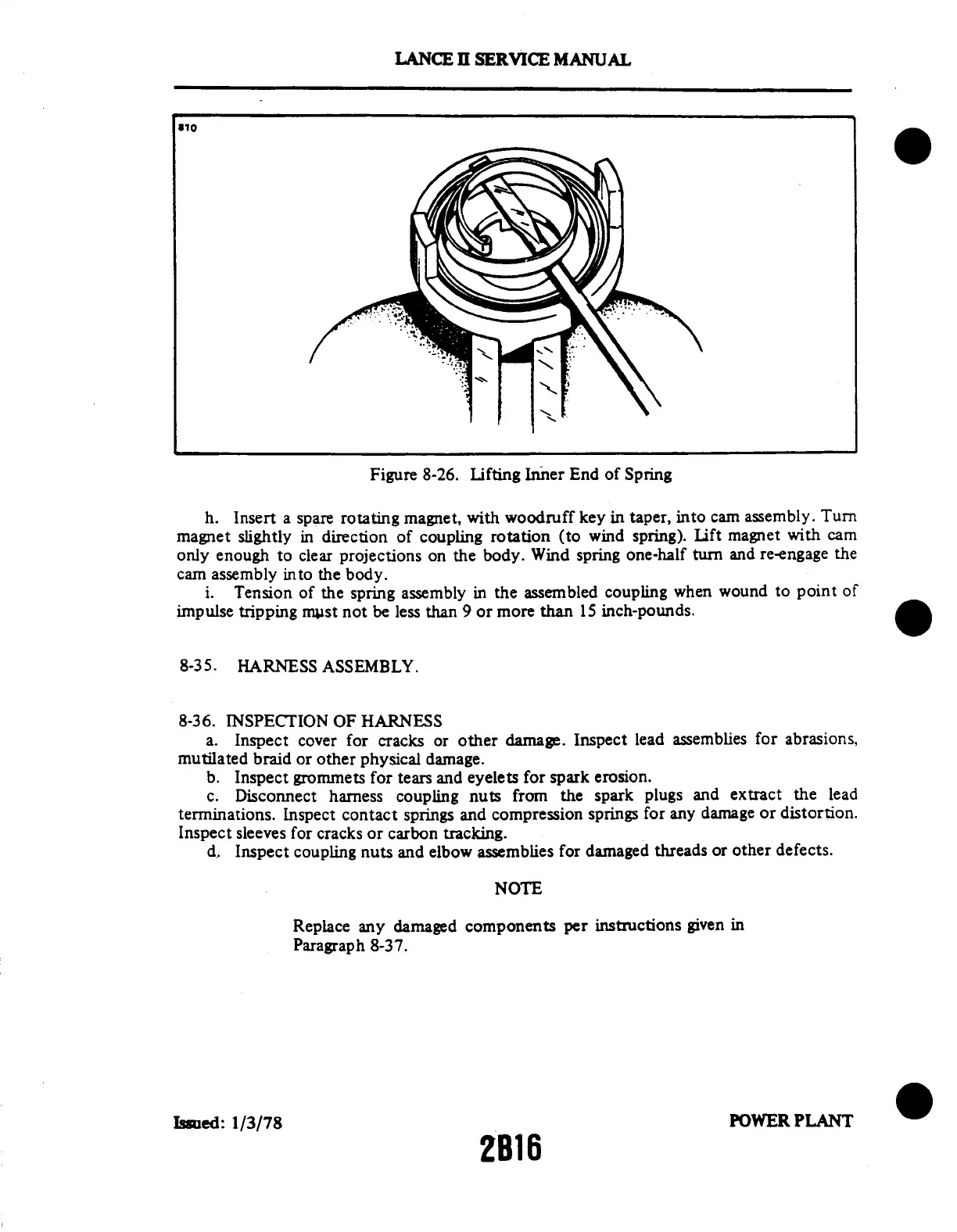

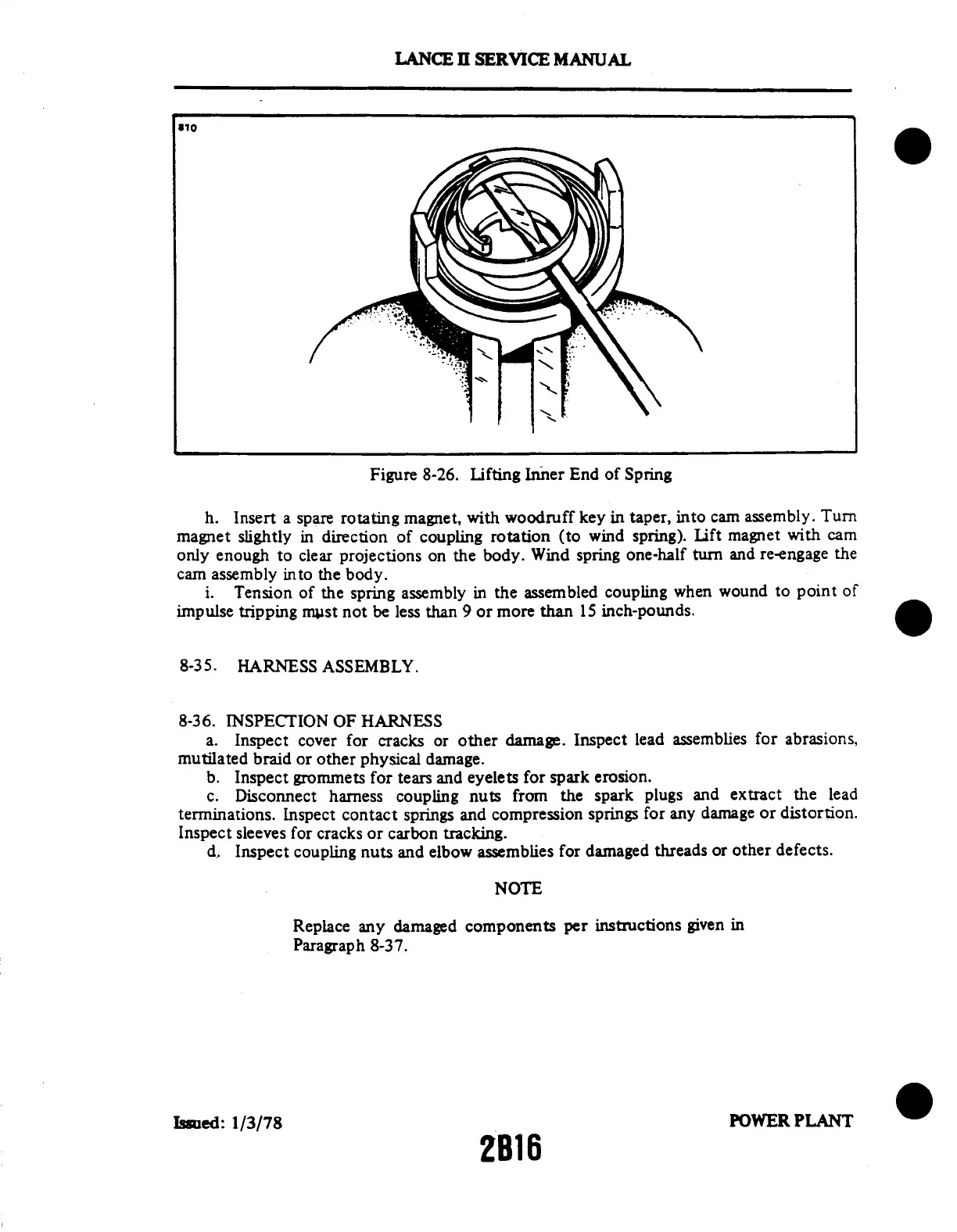

Figure 8-26. Lifting Inner End of Spring

h. Insert

a spare rotating magnet,

with woodruff

key in taper, into

cam assembly.

Turn

magnet slightly

in direction

of coupling rotation

(to wind spring).

Lift magnet with

cam

only enough to clear

projections on the body. Wind spring

one-half turn and re-engage the

cam assembly into the body.

i. Tension

of the spring assembly

in the assembled

coupling when

wound to point

of

impulse tripping must not be less than 9 or more than 15 inch-pounds.

8-35.

HARNESS

ASSEMBLY.

8-36. INSPECTION OF HARNESS

a. Inspect cover

for cracks or

other damage.

Inspect lead assemblies

for abrasions,

mutilated braid or other physical damage.

b. Inspect grommets for

tears and eyelets for spark

erosion.

c. Disconnect

harness coupling

nuts from the spark

plugs and extract

the lead

terminations.

Inspect

contact springs and

compression springs

for any damage

or distortion.

Inspect sleeves for cracks or carbon tracking.

d. Inspect coupling nuts

and elbow assemblies for damaged

threads or other defects.

NOTE

Replace

any damaged

components

per instructions

given in

Paragraph 8-37.

Issued: 1/3/78

POWER PLANT

2B16

Loading...

Loading...