43

INLET MATERIAL SCREENS

Inspection of the Inlet Material Screens on a daily basis is no longer necessary as long as the

following conditions are met.

1. Material drums are stored within the recommended material storage temperature range

and drums are not opened prior to installing the Proportioner Material Transfer Drum

Pumps.

2. Desiccant air dryers are used to dry replacement air as material is removed from the

drums to the Proportioner.

3. Consolidation of old material into a common drum for use is minimized especially the Iso

(A).

If the above conditions are met, inspection of the Inlet Material Screens may be done on a bi-

weekly basis. To check the Inlet Material Screens, proceed as follows:

NOTE! Inspect and clean Inlet Material Screens before Proportioner start-

up. They should not be cleaned after the days operation as the

Proportioner should be purged (see page 19) immediately after inspection

and cleaning. This is to reduce the risk of moisture contamination and

contamination through the reaction with any solvent used in the cleaning

operation and cross-over at the Spray Gun due to air entrapment.

CAUTION! Make sure the Main Power Switch is OFF and incoming

power is locked OFF.

1. CLOSE the Poly (R) Proportioner Inlet Valve.

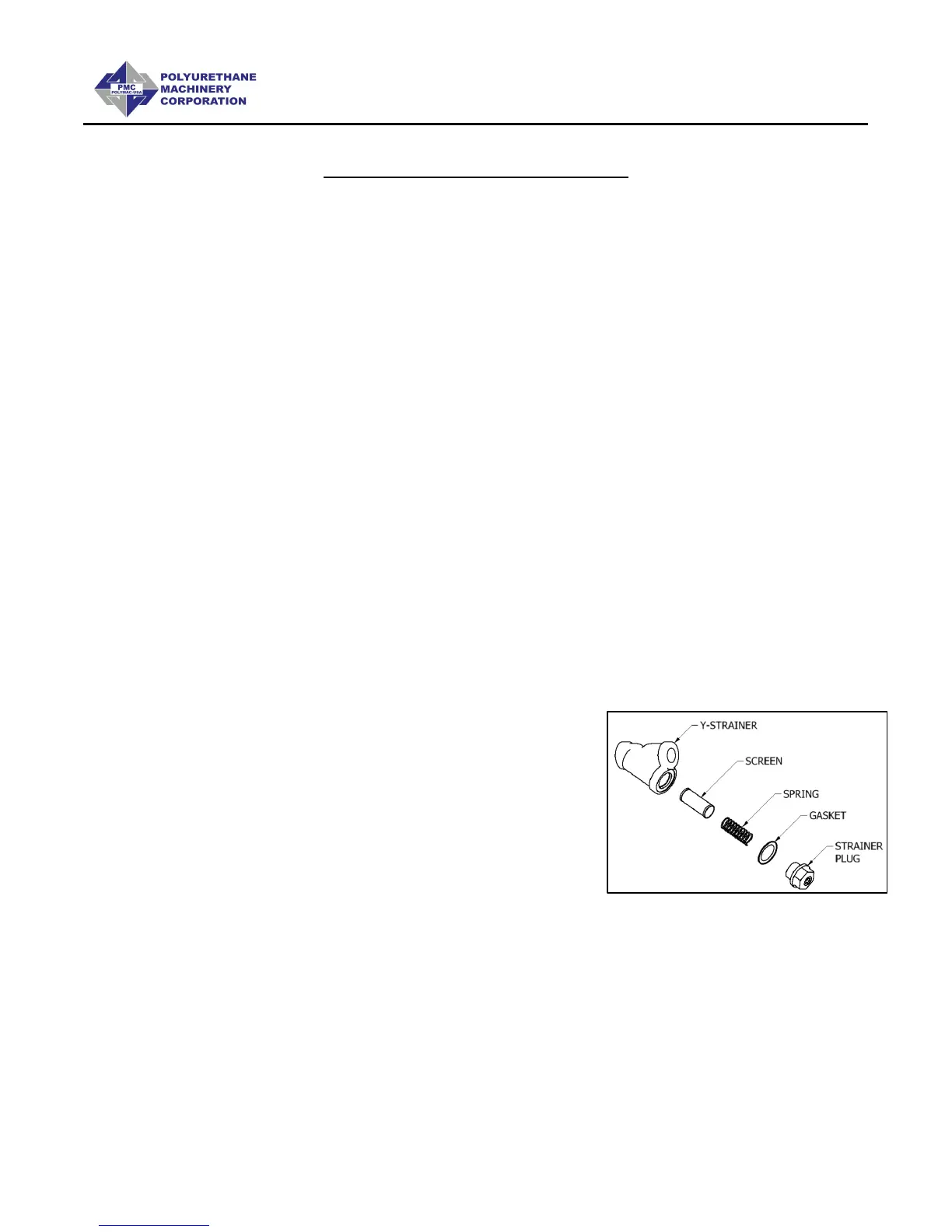

2. Place a suitable container under the Material Inlet

Strainer to collect the residual material. Carefully loosen

the Strainer Plug to drain material into the container.

3. Completely unscrew the Strainer Plug.

4. Remove the Seal, Spring and Screen and clean them with a suitable solvent. Dry the

parts and ensure the Screen is not obstructed. Replace the Screen if more than 20% of

the Screen surface is obstructed by residue.

5. Reinstall the Screen, Spring and Seal. Screw on the Strainer Screw and screw in Plug.

6. OPEN the Poly (R) Proportioner Inlet Valve, pressurize the Material Transfer Pump,

check for leaks and wipe Y-strainer clean.

7. Repeat above for the Iso (A) side.

8. Proceed with Proportioner Purging operation (page 19).

Loading...

Loading...