33

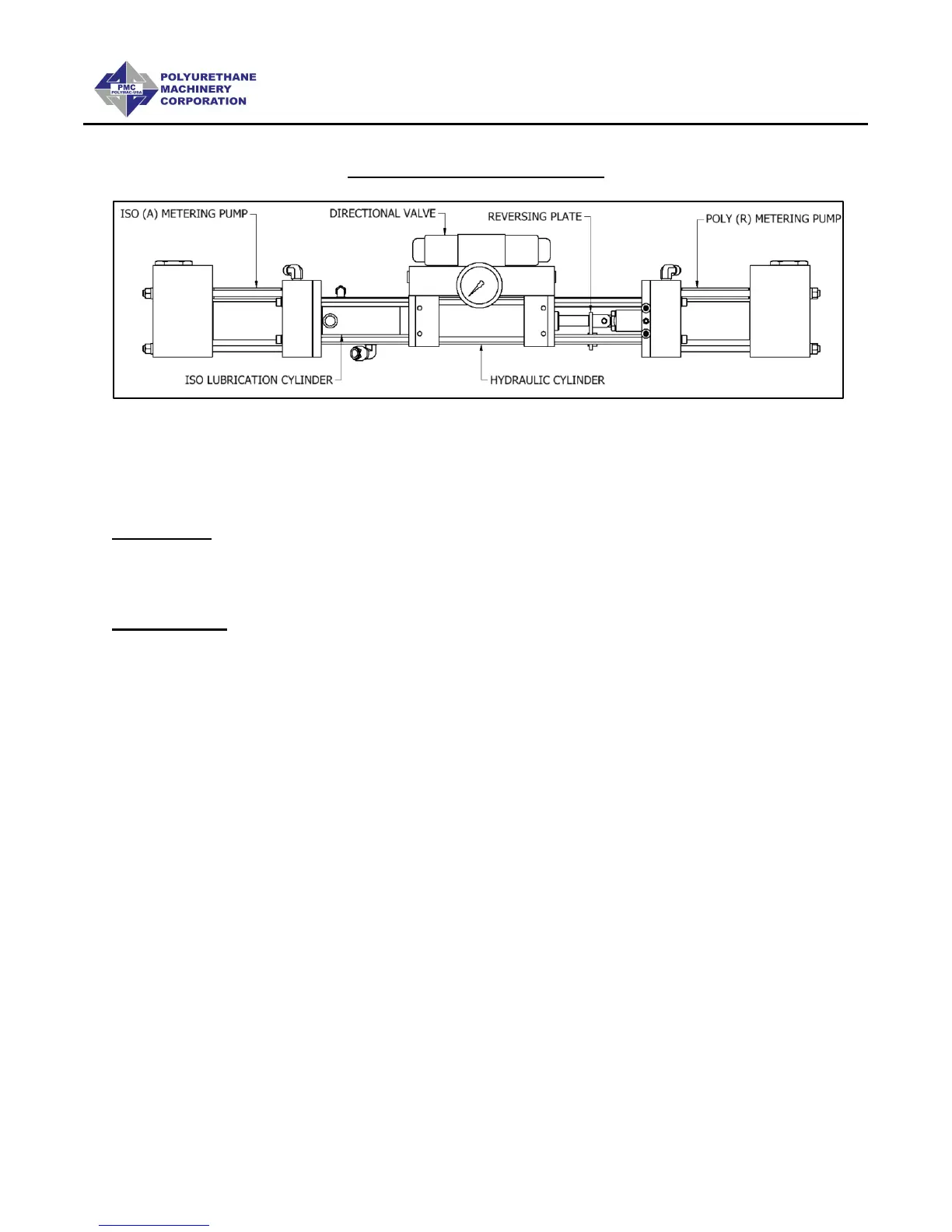

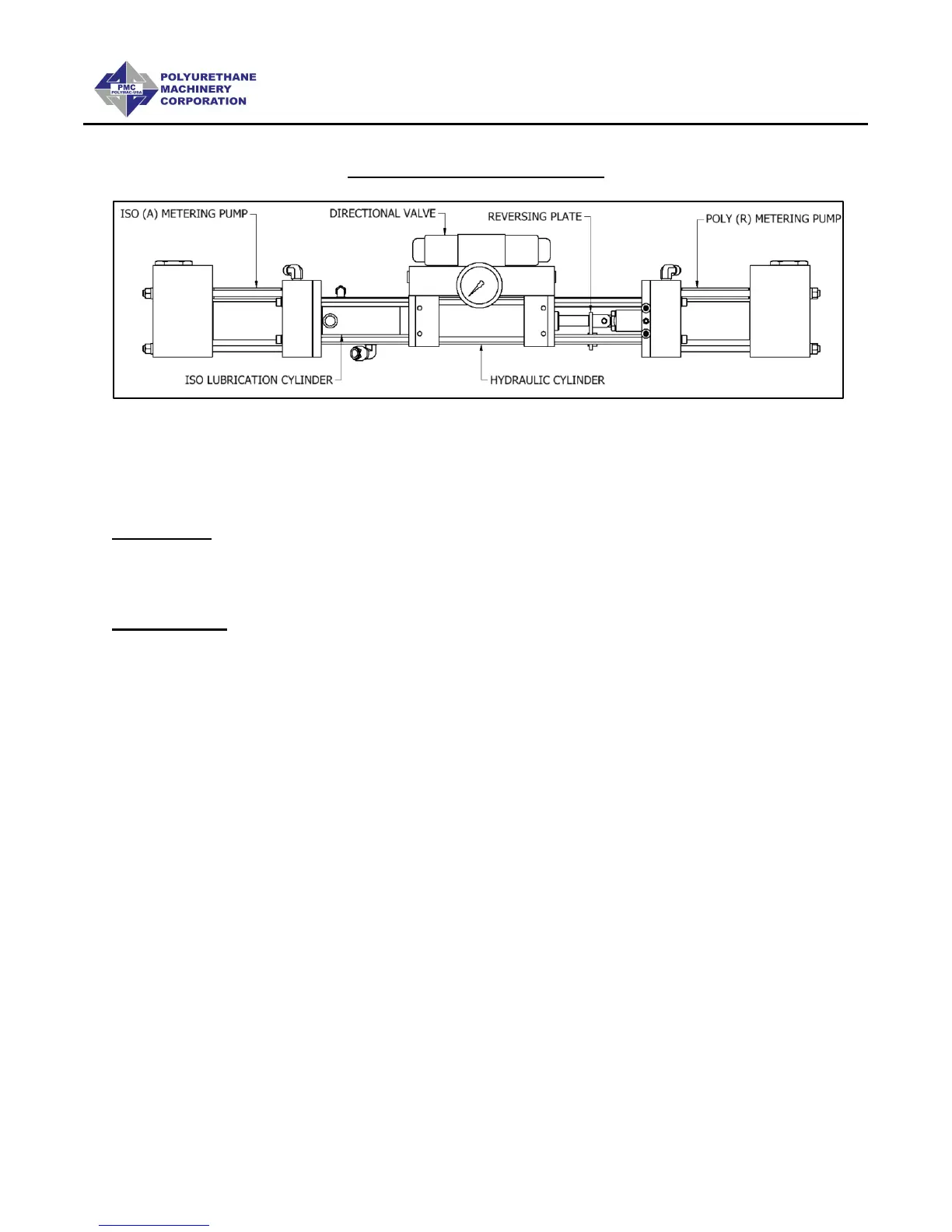

METERING PUMP LINE

Follow the recommended procedures in the indicated order to solve the problem and avoid

unnecessary repairs. Make sure all Switches are in the correct position and Indicator Lights ON

before determining the existence of a fault.

PROBLEM:

Metering pumps do not change direction and the pressures on both of the

chemical gauges are lower than normal.

SOLUTIONS:

1. The Metering Pump Line has a Reversing Plate which actuates two Proximity Switches,

one at each end of the stroke. The Prox Switches in turn actuate the appropriate

Directional Valve Solenoid. Failure to make contact with either PROX Switch may be

caused by:

a. Deformation of the Reversing Plate.

b. Foreign material preventing the Reversing Plate from contacting the Prox

Switches. If this is not the problem, go to the next step

2. Passing of the Reversing Plate beyond the Prox Switch may be caused by:

a. Failure of the Prox Switch and related components on the side of the over-run.

b. Failure of a component of the Directional Valve.

c. Mounting Plate and/or Prox Switch is out of adjustment.

NOTE! IF THE DIRECTIONAL INDICATOR LIGHT IS ON CHECK THE

REVERSING VALVE COIL ON THE SIDE THAT THE LIGHT IS ON. IF

YOU HAVE 24 VOLTS DC AT THE PLUG CHECK THE OHM’S

RESISTANCE OF THE COIL, IT SHOULD READ APPROXIMATELY 19

OHM’s, IF NOT REPLACE THE COIL OR REVERSING VALVE.

Loading...

Loading...