PORTER Reliant

22

6.2 CLEANING THE INSTRUMENTS BEFORE THE STERILIZATION

In order to extend the sterilizer life, we recommend to carry out an accurate cleaning of the instruments;

one of the main causes of an early equipment wear is the settlement and accumulation of debris and

fragments for inadequately instrument cleaning, and consequent stains, fouling and progressive clogging

of filters, electro-valves and tubing.

Thank to the electronic control system, the number of maintenance cycles actually performed is continu-

ously recorded and updated.

The missing of appropriate and regular maintenance according to the above guidelines could cause an

early and more frequent service activities and the lapse of the warranty.

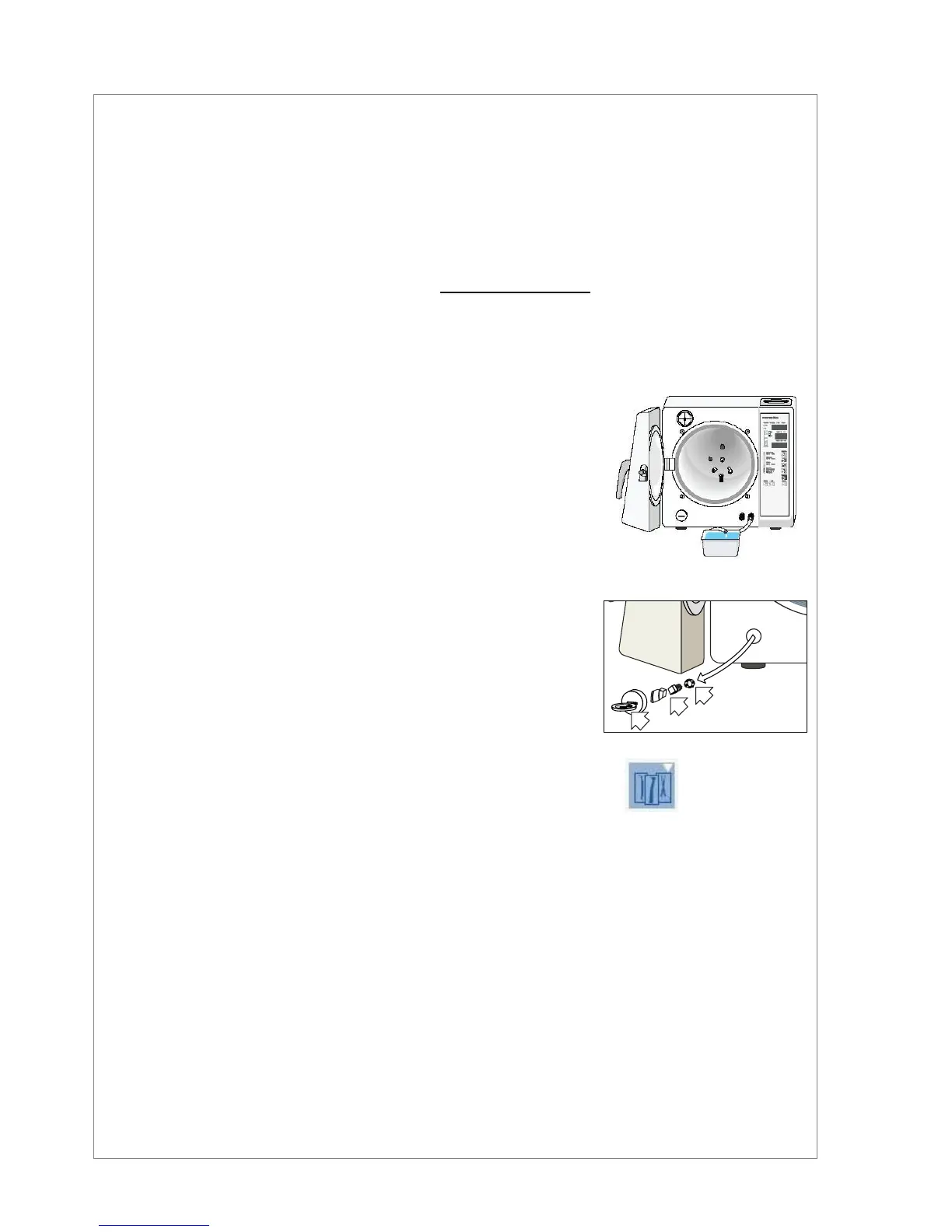

6.3 CLEANING/REPLACING THE WATER FILTER

To carry out the clean or the replacement of the filter mounted left side

the front panel, proceed as follows:

1. Drain completely the main tank by plugging the supply tube into

the white fast fitting of the front panel.

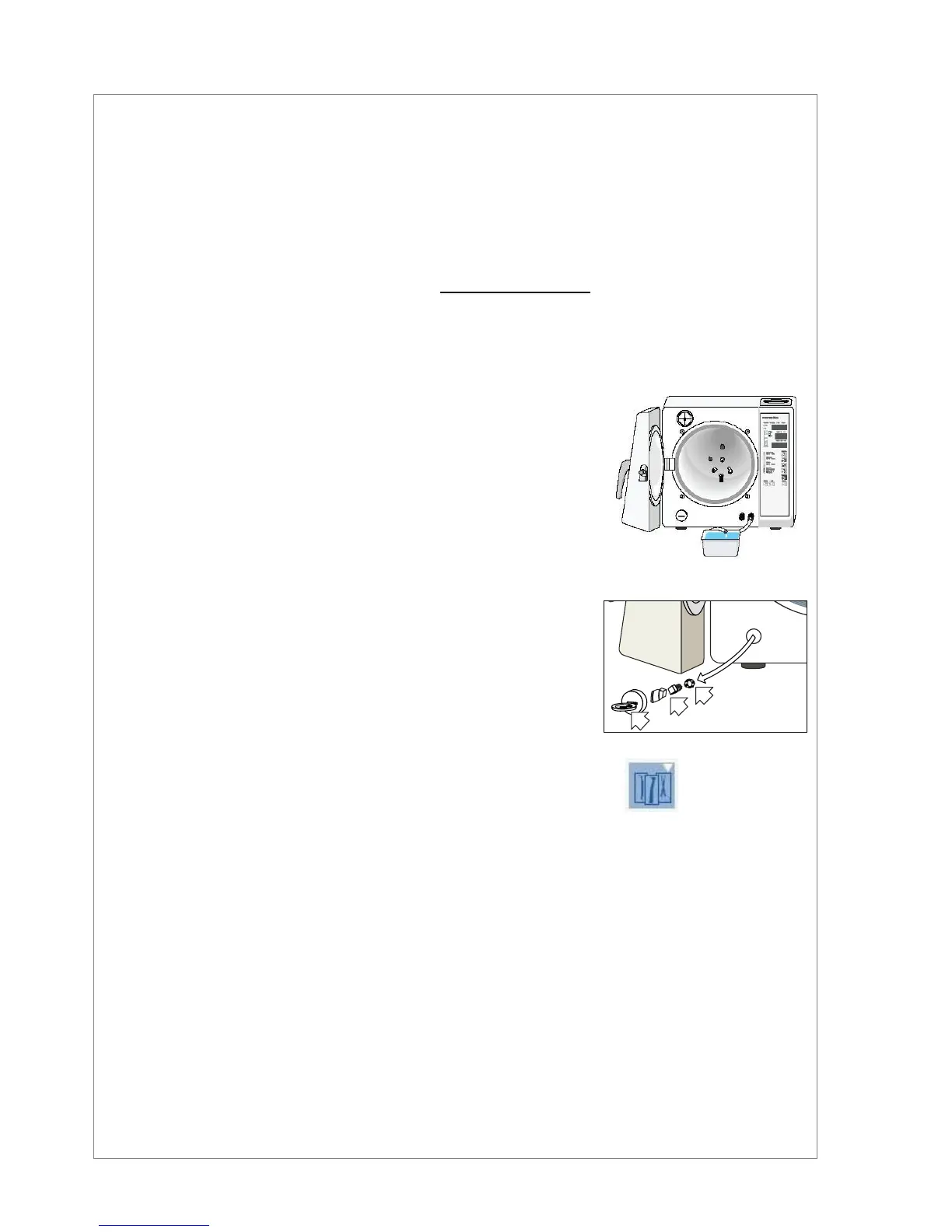

2. Use a coin to unscrew the cap (1) closing the filter seat; pay at-

tention for possible water outflow from the internal tubes. Un-

screw the filter holder (2) using the supply spanner.

3. Clean the filter (3) by compressed air (or ultrasonic cleaner) or

replace it if damaged.

4. Remount filter, filter holder and cap; screw down by hand with-

out tightening excessively.

5. Fill the main tank with demineralized water as for the standard

operation.

6. With the unit in stand-by (OFF on the display), hold down the key and push the key

Power

. The equipment starts an automatic initialization procedure, with the exhausting of the re-

sidual air from the filter. The end of the procedure is indicated by the Led READY

6.4 REGULAR STERILITY TESTS

During the factory tests and according to the standing regulations, the sterilizers are deeply tested and the

calibrations checked; these tests warrant the sterilizer performances except for unauthorized interven-

tions, tampering or an improper usage. Although the unit is equipped with an advanced diagnosis and

process evaluation system, it user responsibility to check the performance during the unit life. For a proper

usage of the sterilizer, it is necessary to carry out functionality tests periodically. The frequency of these

checks is regulated at local country level, check the regulations in force.

For any explanations or information contact your authorized reseller or directly Porter.

Loading...

Loading...