PORTER Reliant

25

8. ALARMS

8.1 GENERAL

With equipment switched on and during every cycle, the supervisory system of the equipment constantly

monitors the characteristic parameters of the different sterilization phases, the proper operation and the

status of the devices. Any detected anomaly or fault is promptly signalled through specified messages,

coded alarms and acoustic signalling.

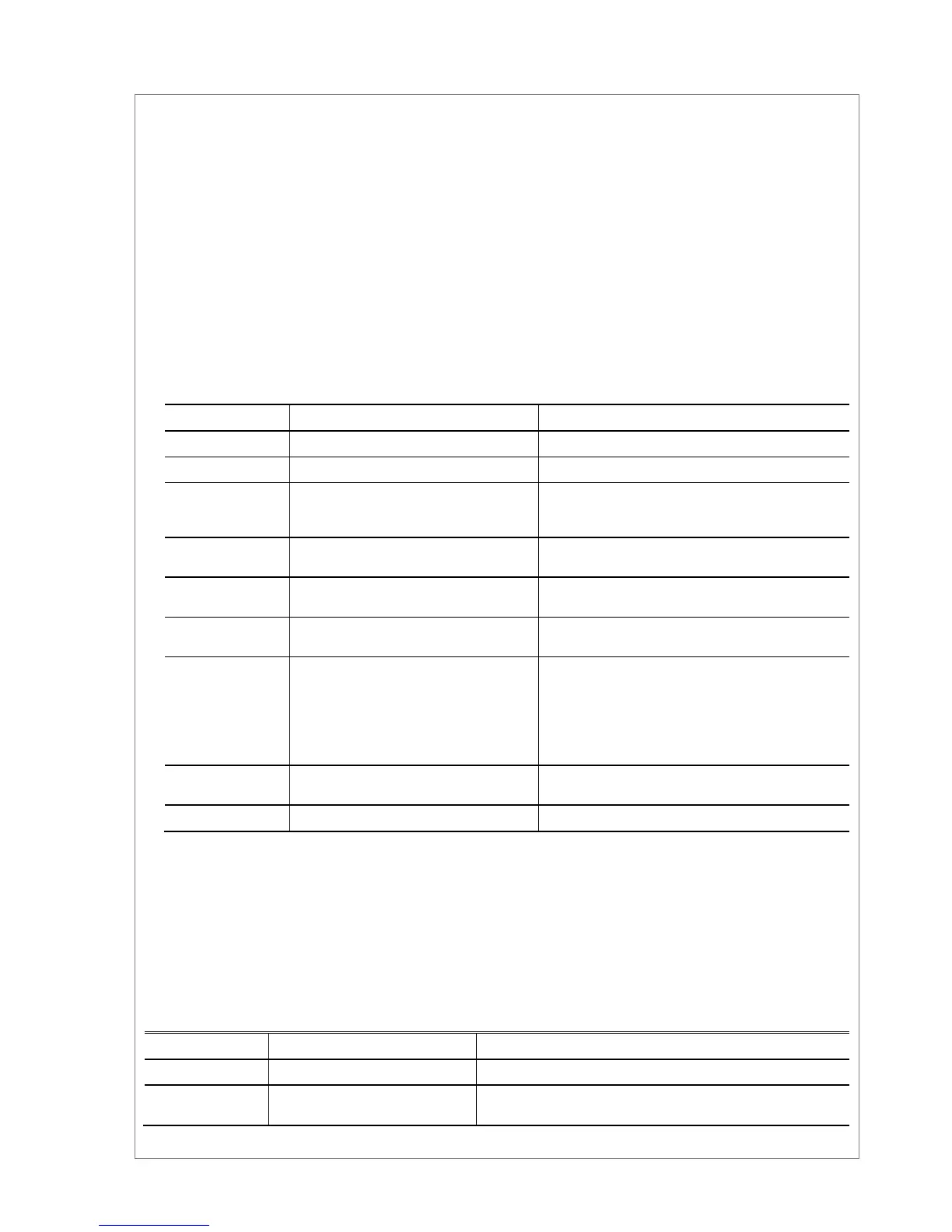

To easy the interpretation and identification, the alarms have been divided into three classes, as shown in

tables A, B, and C.

8.2 WARNING MESSAGES

TABLE A

Insufficient water in the main tank (the

message appears before starting a cy-

cle)

Perform the topping up of the main tank.

Cycle manually interrupted. The sterili-

zation process not completed

Wipe the chamber, if wet, and start again the cycle

Black-out occurred during the cycle

Check the AC voltage.

Wipe the chamber and repeat the cycle.

60 cycles carried out from the last

automatic cleaning cycle

Perform the automatic cleaning cycle (see Chapter

6.1)

One year from the installation

or over 2000 cycles performed without

any service check-up

The warning message disappears as soon as a

cycle is selected, but will appear again at the next

switching on.

Call for a complete check by a qualified technical

service; the message will be reset after the servic-

ing.

Need for the installation procedure.

Perform the installation procedure (see Chapter

3.2)

Detected a pre-warning alarm

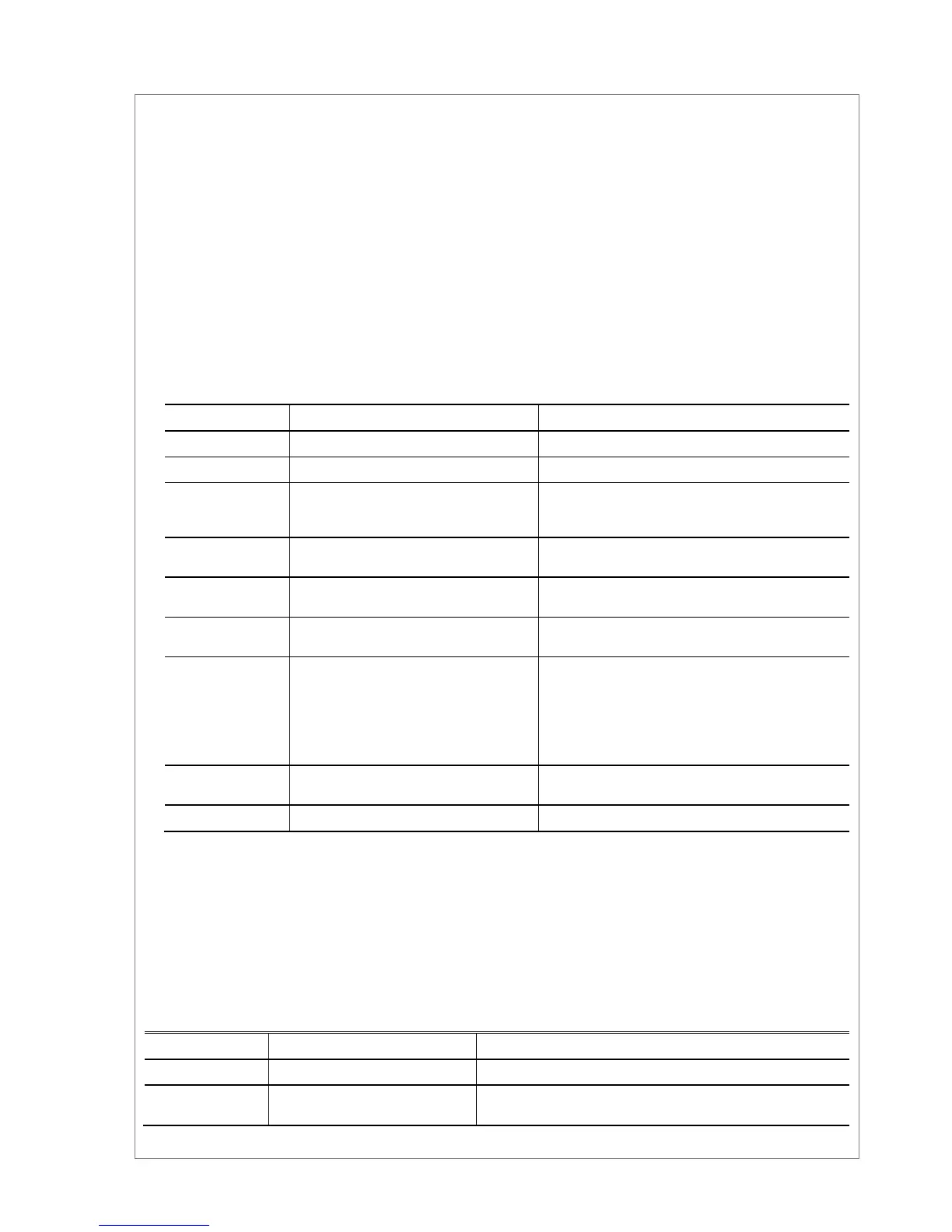

8.3 PRE-WARNING ALARMS

The alarms shown on table B do not stop the sterilizer operation, but warn that a problem may interfere with the cor-

rect sterilizer operation.

The trouble should be checked and the recommended action promptly performed.

In case of fault, the message Need Test will appear together with the code number of the detected alarm.

Example: Need Test cd 1.

TABLE B

Clean or replace the filter

Slow heating of the chamber

Perform a cycle with reduced load. In case, call for a techni-

cal service. Check the AC voltage.

Loading...

Loading...