Powered by Safety

®

38

Installation

Power/Vac® Metal-Clad Switchgear 5kV & 15kV

01.4IB.67000

3. Sixteen sets of 0.38 x 1” hardware is

provided for perimeter bolting. The

following guidelines shall be followed:

a. Minimum of 3 bolts on each vertical

post.

b. For 82” deep and 94” deep stacks,

a minimum of two bolts on each

depth post with at least one bolt in

the front compartment and one bolt

in the rear compartment.

c. For 106” deep stacks, a minimum

of three bolts on each depth post

with at least one bolt in the front

compartment and one location in

the rear compartment.

Where there are no accessibility issues it

is generally recommended that perimeter

bolting be done at all 16 locations.

Note: If the units have to be moved or lifted

after installation, they should be lifted

only at the shipping splits

L. CONNECTIONS

1) Main Bus Bars

The main bus bars and other connection

bars are either copper or aluminum. The

connection surfaces are silver surfaced

or equivalent. The silver plating used on

bolted contact surfaces is approximately

0.0001” thick; plating on sliding contact

surfaces is thicker. All field assembled joints

in primary conductors should be made as

follows:

1. Wipe the surface clean with a lint-free

cloth. Do not use sandpaper or any

other abrasive material on the plated

surface. Avoid handling of cleaned

surfaces as much as possible. If the

surface is tarnished, clean it with silver

polish and then wash it with denatured

alcohol.

2. Join the clean contact surfaces by using

the hardware provided.

The correct length of bolt must be

used in each joint to ensure that

electrical clearances at bolt locations

are maintained. As a general rule,

when using / inch diameter bolts, the

bolts should be 1 inch longer than the

combined thickness of the copper bars

being bolted together.

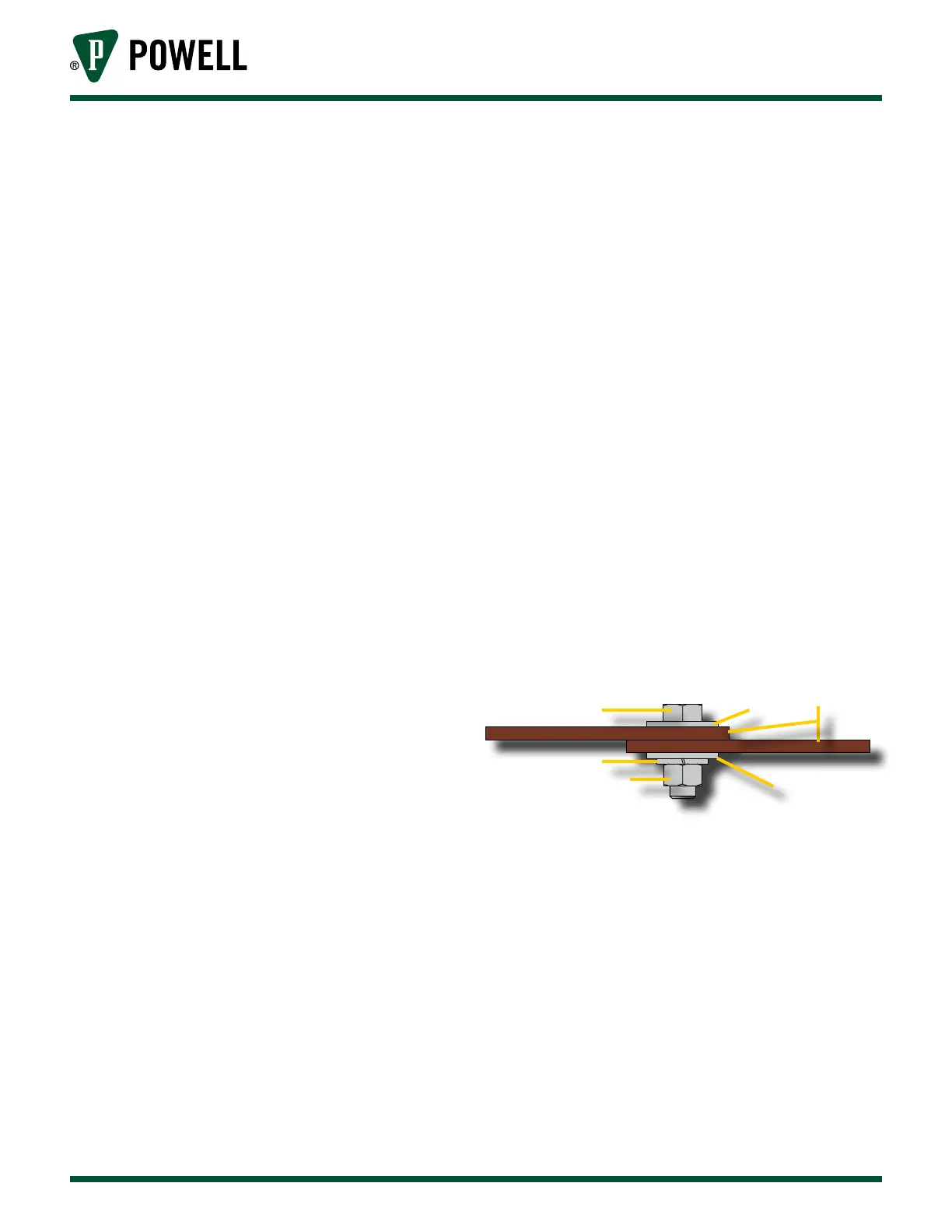

For example, if three / inch thick

copper bars are to be connected,

the bolt should be 1/ inch long In

addition to proper length bolts the bolt

assembly must include flat washers split

ring lock washers and nuts All bus joint

hardware is zincplated dichromate

treated high strength steel Cap screws

are / - 13 SAE Grade 5. See Figure 29

for proper hardware assembly.

Figure 29 Ground Bus Splice Bolt Assembly

a

b

b

c

d

e

a. Bolt

b. Flat Washer

c. Bus Bar

d. Split Lock Washer

e. Nut

3. In some cases, external connections are

made to metal-clad switchgear bus by

bars. The metal-clad switchgear bars

are normally silver plated. Unplated

bars, either copper or aluminum, should

not be used to connect to plated bars.

4. All field assembled primary conductor

joints and terminations must be

Loading...

Loading...