Powered by Safety

®

42

Installation

Power/Vac® Metal-Clad Switchgear 5kV & 15kV

01.4IB.67000

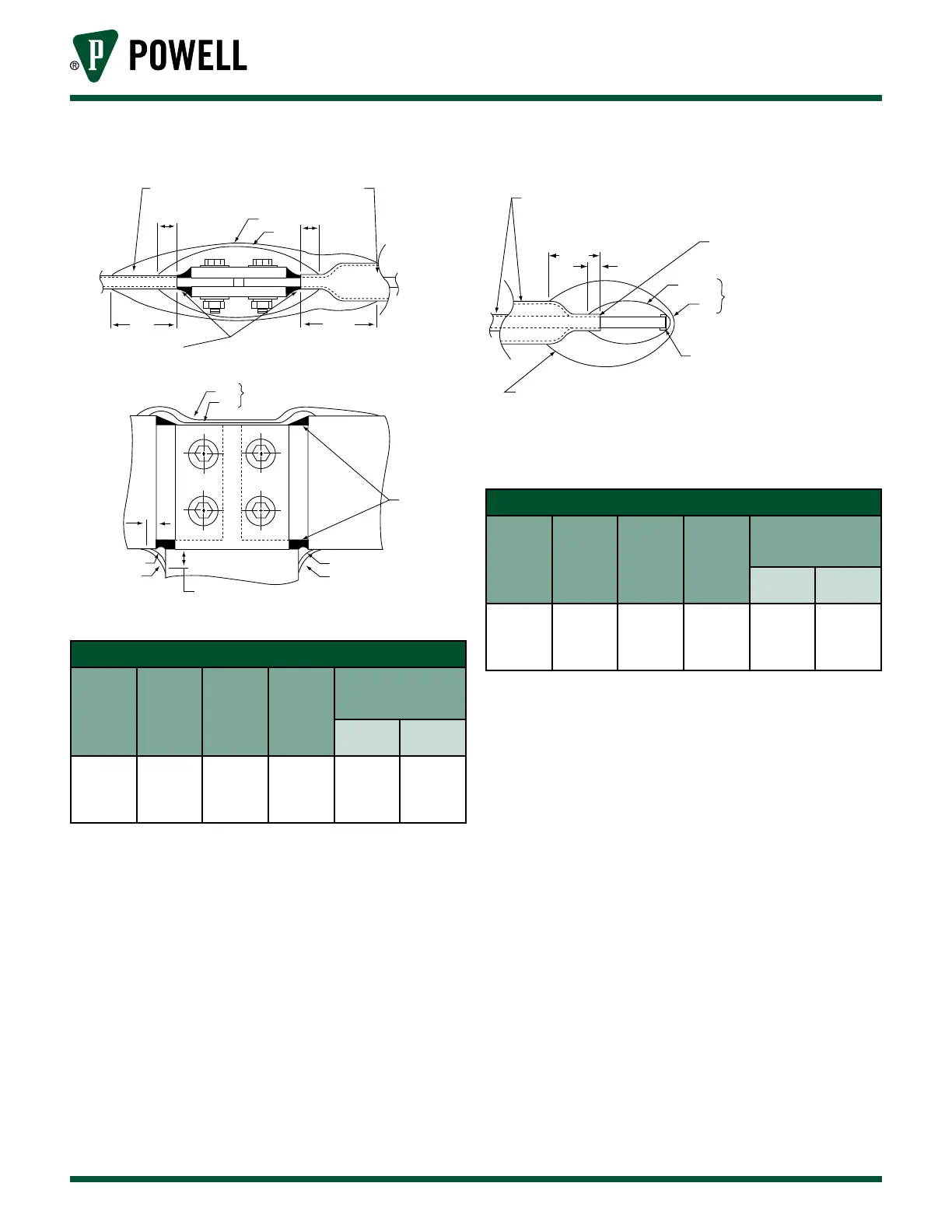

Figure 33 Tee Connection Joint

+

+

+

+

Epoxy Insulation Thermoplastic Sleeving

or Tape Insulation

.50 (12.7)

Min

.50 (12.7)

Min

“A”

“B”

“C”

“C”

“B”

“A”

Overlap Tape in a

Figure Eight Pattern

RB Putty *

Both Ends

RB Putty *

Both Ends

.50 (12.7)

Min

“A”

“A”

“B”

“B”

.50 (12.7)

Min

Table H Insulation of Tee Connection Joint

Insulation

Level (kV)

Inner Filler

“A”

Outer Wrap

“B”

“C”

(inches)

Approx. Number of

Rolls per Joint of HV

Tape ∆

2” or 3”

Bars

4” or 6”

Bars

5 or 15

RB Putty* &

3 Layers HV

Tape ∆

2 Layers

HV Tape ∆

3

/ Roll RB

Putty *

1 Roll HV

Tape ∆

1 Roll RB

Putty *

2 Rolls HV

Tape ∆

Note: * Electrical grade rubber based putty

0282A3529 P008 in roll form will be

used to grade voids and smooth out

sharp edges of joints. This putty has

no insulation value.

1 roll is /” x 1½” x 5’ long.

∆ HV Tape 0282A3529 P004 roll

is .030” x 2” x 30’ long. Apply with

mastic side down.

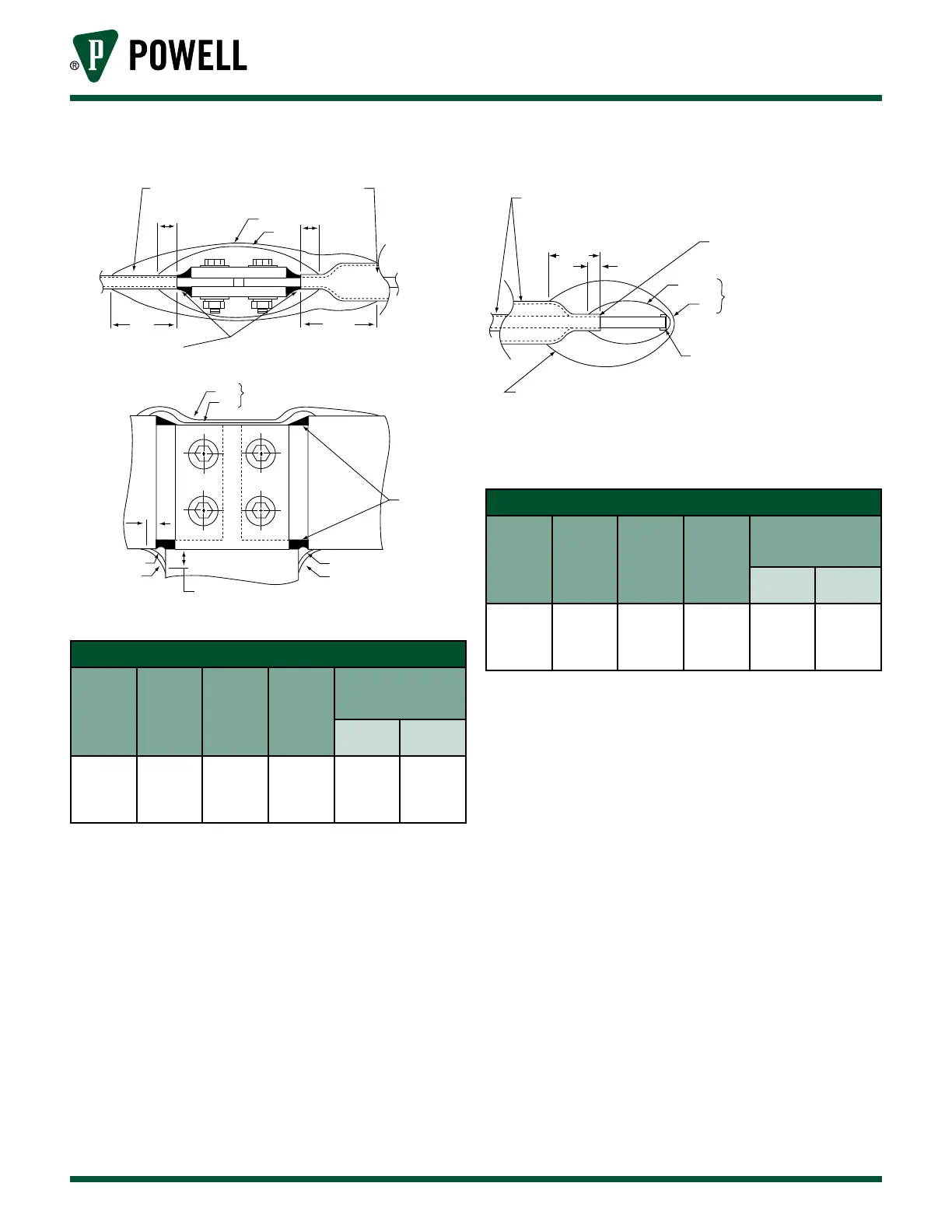

Figure 34 Dead End Bus Joint Insulation

“C”

Min

50 (12.7)

Min

“B” Layers - 1/2 LAP

Pre-Insulation Epoxy Insulation

Thermoplastic Sleeving or Tape Insulation

Apply RB Putty Sparingly

to Grade-Out and Round O

Pre-Insulation

“A”

“B”

Crisscross Tape in a

Figure Eight Pattern to

Fully Cover End

1) Cut and Apply 1-Strip of

Tape to Form a Boot Over End

2) Apply RB Putty Sparingly

to Round O End of Bar

3) Continue with “A” Layer

of HV Tape.

Table I Insulation of Dead End Bus Joint

Insulation

Level (kV)

Inner Filler

“A”

Outer Wrap

“B”

“C”

(inches)

Approx. Number of

Rolls per Joint of HV

Tape ∆

2” or 3”

Bars

4” or 6”

Bars

5 or 15

RB Putty* &

3 Layers HV

Tape ∆

3 Layers

HV Tape ∆

3

/ Roll RB

Putty *

/ Roll HV

Tape ∆

/ Roll RB

Putty *

1 Roll HV

Tape ∆

Note: * Electrical grade rubber based putty

0282A3529 P008 in roll form will be

used to grade voids and smooth out

sharp edges of joints. This putty has

no insulation value.

1 roll is /” x 1½” x 5’ long.

∆ HV Tape 0282A3529 P004 roll

is .030” x 2” x 30’ long. Apply with

mastic side down.

Loading...

Loading...