Chapter 5 Function parameter

90

factory defaults, the new parameter setting takes effect. If it is higher than factory defaults will

be the standard value.

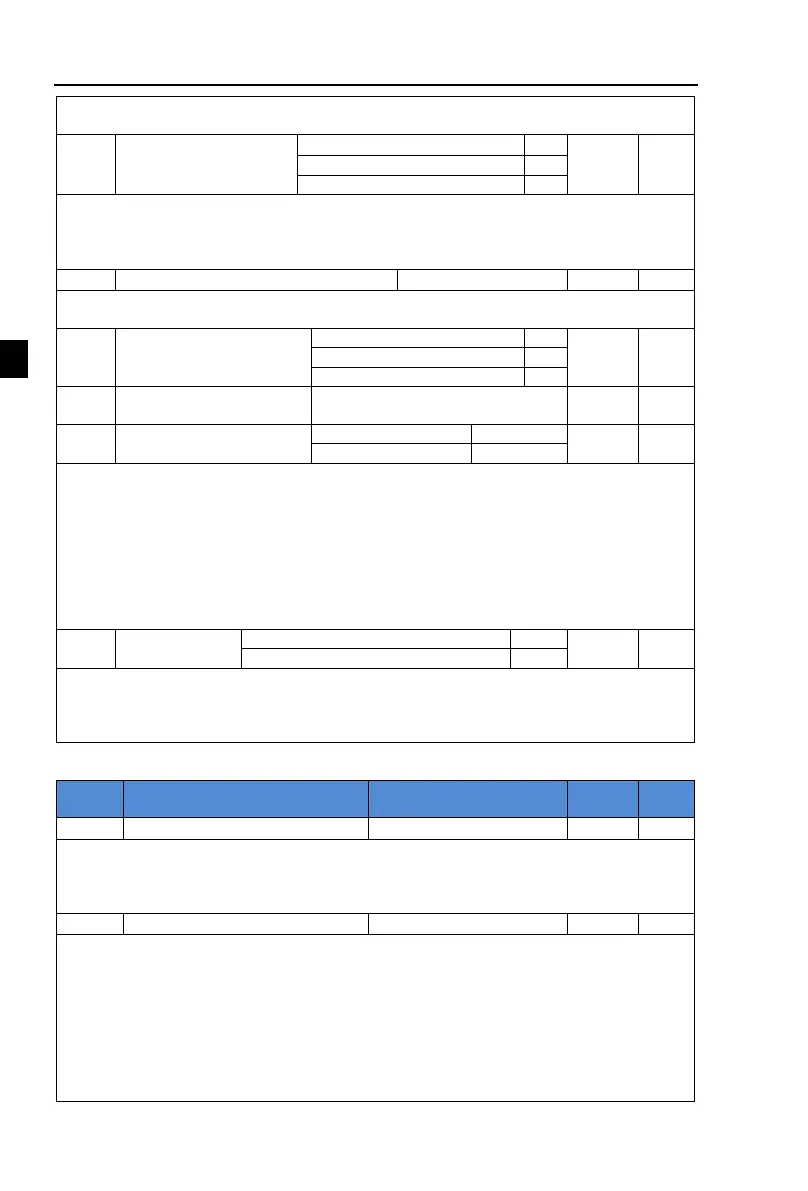

Deadband compensation

mode selection

Generally do not need to modify this parameter, only when the special requirements to the

output voltage waveform quality is required or when the motor oscillation and other abnormal

happen, you need to try to switch to select a different mode of compensation.The compensation

mode 2 for high-power is recommended.

Current detection compensation

Used to set the inverter's current sensing compensation, if the set value is too large, which

may reduce the control performance. Generally do not need to be modified.

Vector optimization

without PG mode selection

Upper limiting frequency

for DPWM switching

Only valid for V/F control. Synchronous modulation refers to that the carrier frequency

linearly change with the change of output frequency, in order to ensure the unchanged of their

ratio(Carrier to noise ratio), generally it is used when the output frequency is higher, is

conducive to ensure the output voltage quality.

Under the lower output frequency (100Hz) mode, generally the synchronize modulation is

not required, because at the time the ratio of the carrier frequency to the output frequency is

relatively high, the asynchronous modulation has more obvious advantages.When the operating

frequency is higher than 85Hz, the synchronous modulation takes effect, the fixed mode is the

asynchronous modulation below the frequency.

PWM carrier frequency random depth

By setting Random PWM, the monotonous and shrill motor sound can become softer and

which helps reduce external electromagnetic interference. When Random PWM Depth is set to

0, Random PWM will be invalid. It will get different results by adjusting different Random

PWM Depths.

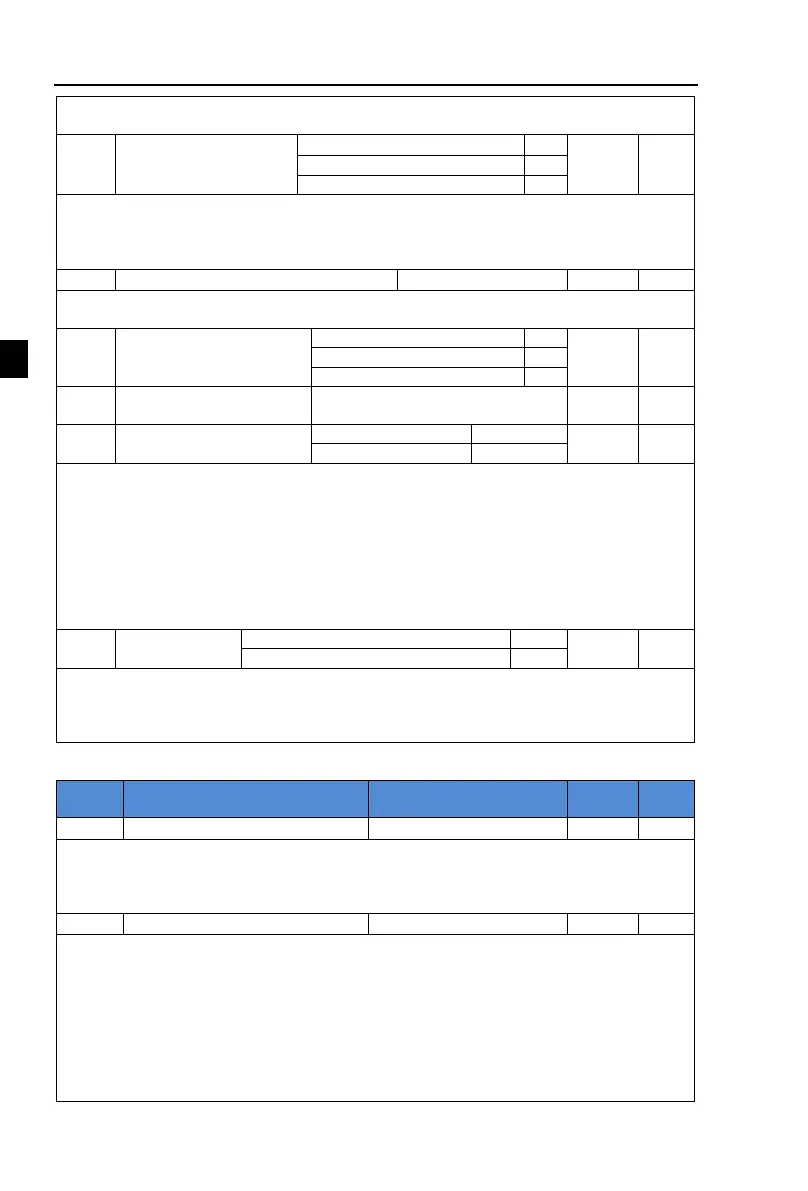

5-2-14.FC group Extended parameter

Proportional linkage coefficient

When proportional linkage coefficient is 0, proportional linkage function can not

work.According to the setting by proportional linkage, communication address of master

(F9.02) is set to 248, and communication address of slave is set to 1 to 247.Slave output

frequency = Master setting frequency * Proportional linkage coefficient + UP/DOWN Changes.

If the absolute value of deviation between PID setting source and feedback source is

greater than of the parameter, the inverter starts only when PID output frequency is greater than

the wake-up frequency to prevent the repetition of the inverter starts.If the inverter is operating,

when PID feedback source is greater than setting source and the output frequency is less than or

equal to (F7.48) sleep frequency, the inverter goes to sleep after (F7.49) delay time and

performs free stop.

If the inverter is in the state of sleep and the current run command is valid, the absolute

value of deviation between PID setting source and feedback source is greater than of PID start

deviation (FC.02), when PID setting frequency is greater than or equal to F7.46 wake-up

Loading...

Loading...