Copyright © Prins Autogassystemen B.V. 2011

23

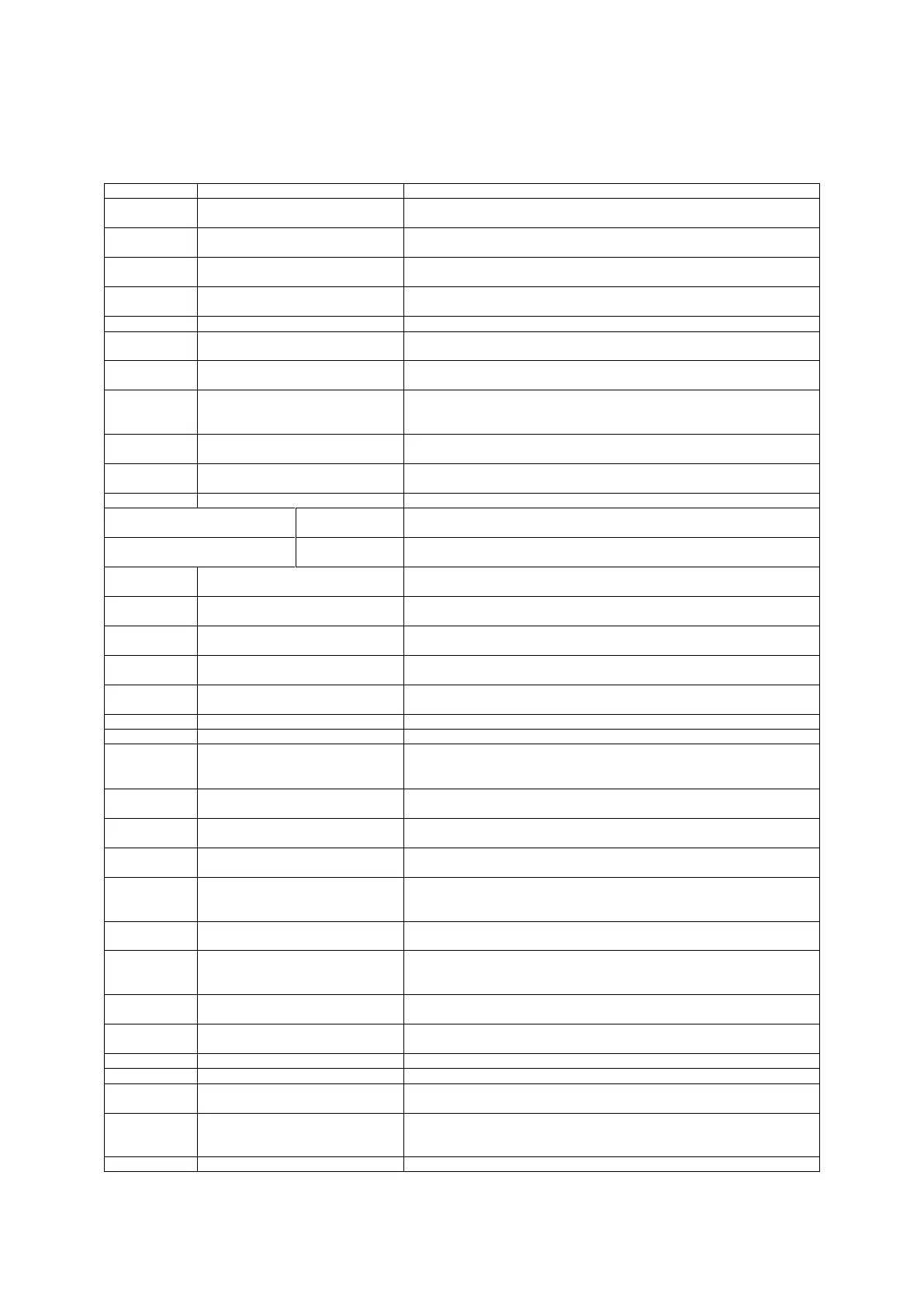

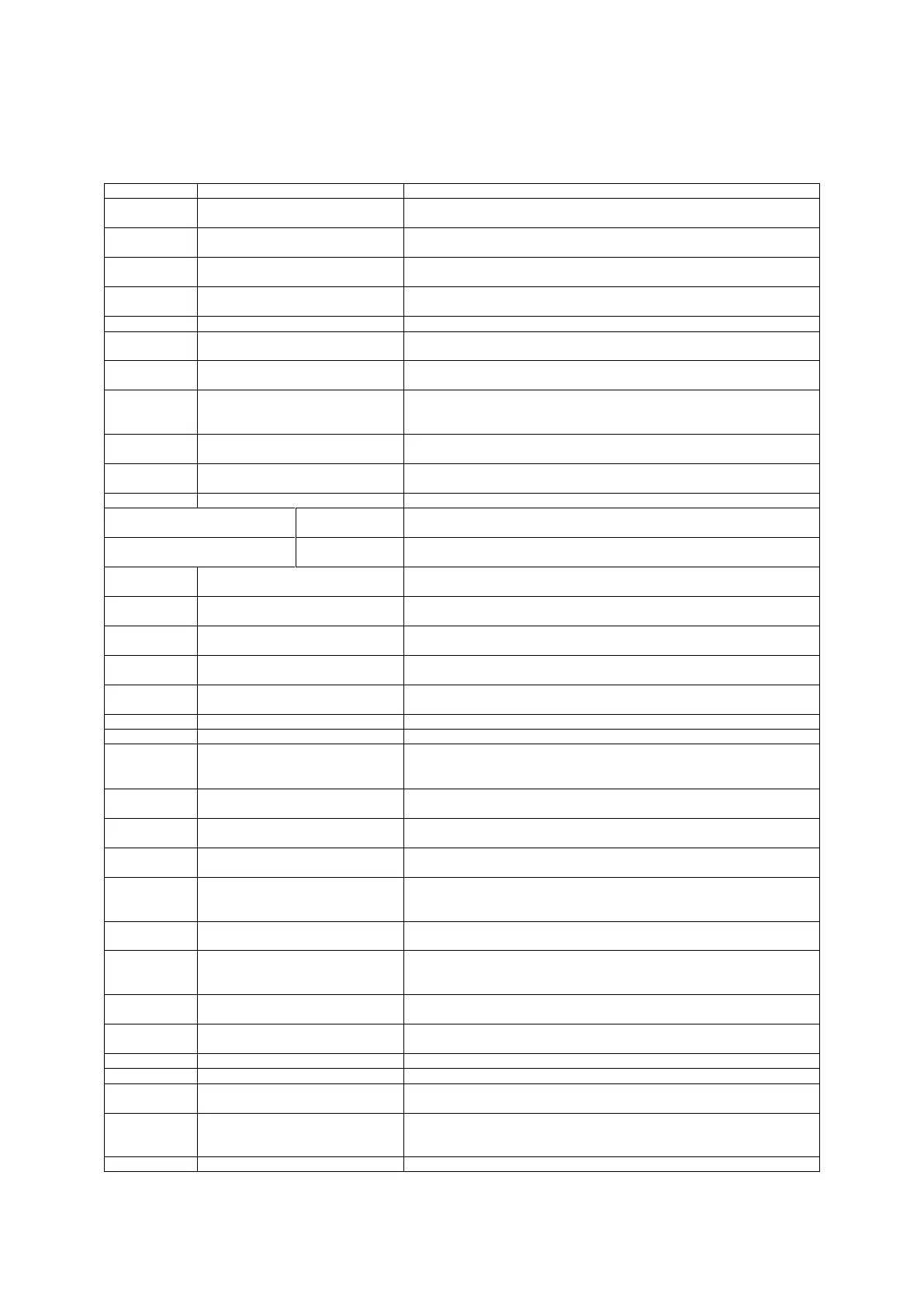

Trouble code chart

Check when operating on petrol and LPG that there is good lambda

signal movement.

Check when operating on petrol and LPG that there is good lambda

signal movement.

Lambda to long to lean during open

loop.

Check when operating on petrol and LPG that there is good lambda

signal movement.

Check if the ECT sensor (blue) in the reducer is connector is connected

to ground.

Check if the ECT sensor (blue) in the reducer has a power connection.

Check the ground connection of the Pressure/temperature sensor in the

filter unit.

Check the power connection of the Pressure/temperature sensor in the

filter unit.

Based on a pressure drop in the system, this can be caused by an empty

LPG tank, incorrect solenoid valve, polluted filter or incorrectly adjusted

pressure.

Activate the LPG computer with the diagnostic program, using the F11

function key.

LPG computer circuit board to hot, replace the VSI computer in a cooler

area.

Check board voltage / alternator output and condition of the battery.

210-220-230-240-250-260-270-

280

Injector current to high, check for short circuiting

211-221-231-241-251-261-271-

281

Injector current to low, check for bad connections.

Adjusted pressure on idle out of

range

Adjust the idle pressure to the value shown by parameter “ Idle Level “

Programm error during flahing the

memory

Check parameter settings, contact Prins Autogassystemen.

Check the ground connection of the Pressure/temperature sensor in the

filter unit.

Check the power connection of the Pressure/temperature sensor in the

filter unit.

Check the coolant temperature (T-ect) and the evaporator for leakage of

the first stage.

unexpected parameter change

Contact Prins Autogassystemen.

Check the water connections / circuit.

Gas leakage, system pressure is less

then 1.25 bar after 4 hours when the

engine is not running

Check the system for gasleakage.

System switches to LPG but

engine stalls immediately.

LPG tank empty ?

Lock-off valves open ?

No injection timing on LPG ( 0

Msec.)

Check the injection module.

The LPG system switches

constantly between LPG and Petrol

- Check coolant system for air.

- T-ect sensor in the evaporator malfunction.

Engine hesitates on high revs, and

not running on all cylinders. Engine

runs good on idle.

Check for kinked or jammed LPG hoses (between VSI injector and

couplings).

Check for blocked inlet couplings.

Switch LED’s don’t lit up

Check the main fuse of the VSI system

Check ignition+ (VSI wire 13)

Fault codes when turning the

ignition off ( key out the ignition )

Caused by different switch off times between ignition+ and injector

power.

Connect VSI wire 13 to the petrol injector feed instead of ignition+.

The orange LED on the switch

flashes

Activate the LPG computer with the diagnostic program, using the F11

function key.

The LPG system switches to LPG

but engine stalls immediately

Not running on all cylinders on lpg

Check parameter 10, number of cylinders.

No injection times on lpg

Check the connections of the injection module.

Injection time “falls” to 0 mSec on

LPG

Check the injection module.

Check engine while running on

LPG, injector circuit malfunction,

no lambda control (limb home)

Not starting / running on petrol

Check the connections of the injection module.

Loading...

Loading...