13

5. CALCULATING "RATE 1 AND RATE 2 CAL"

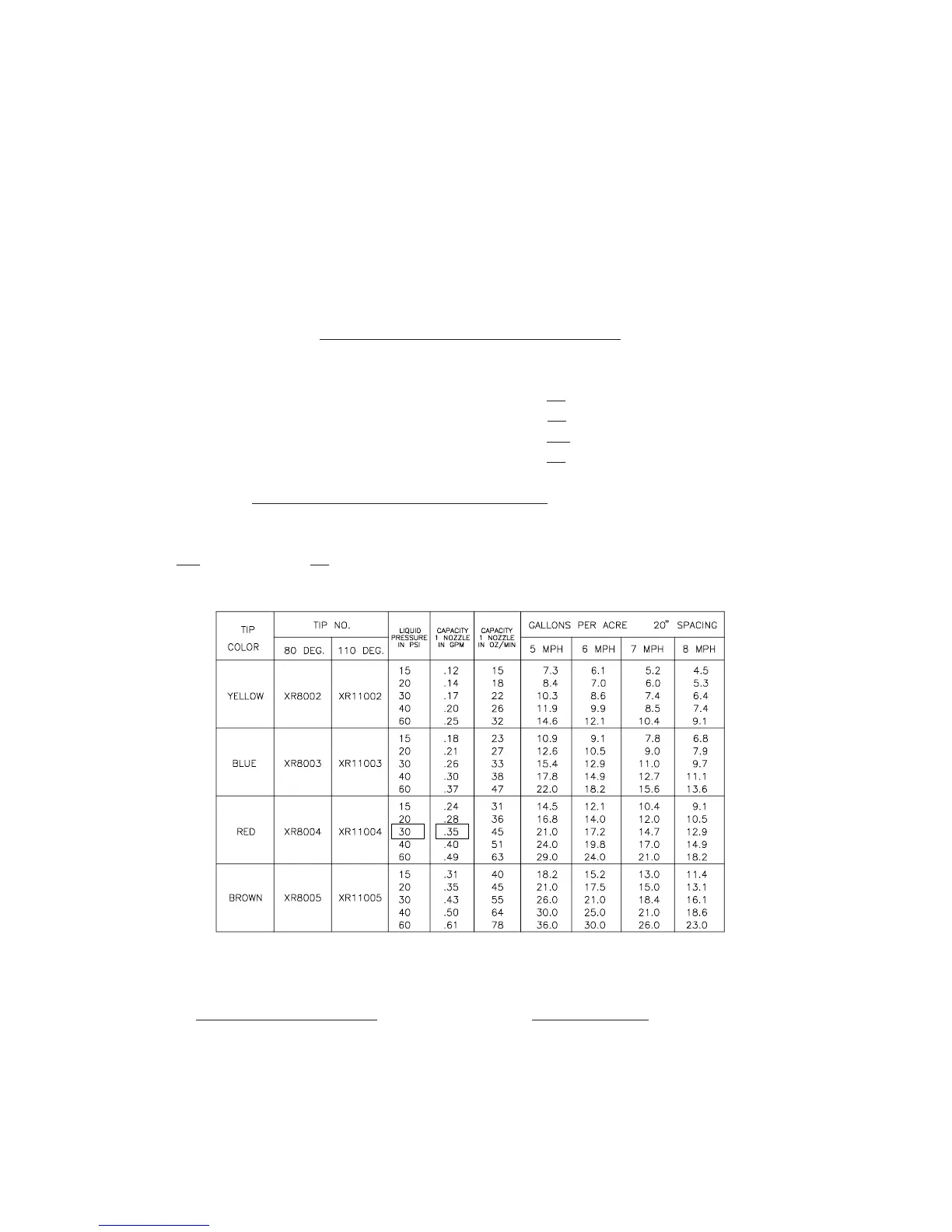

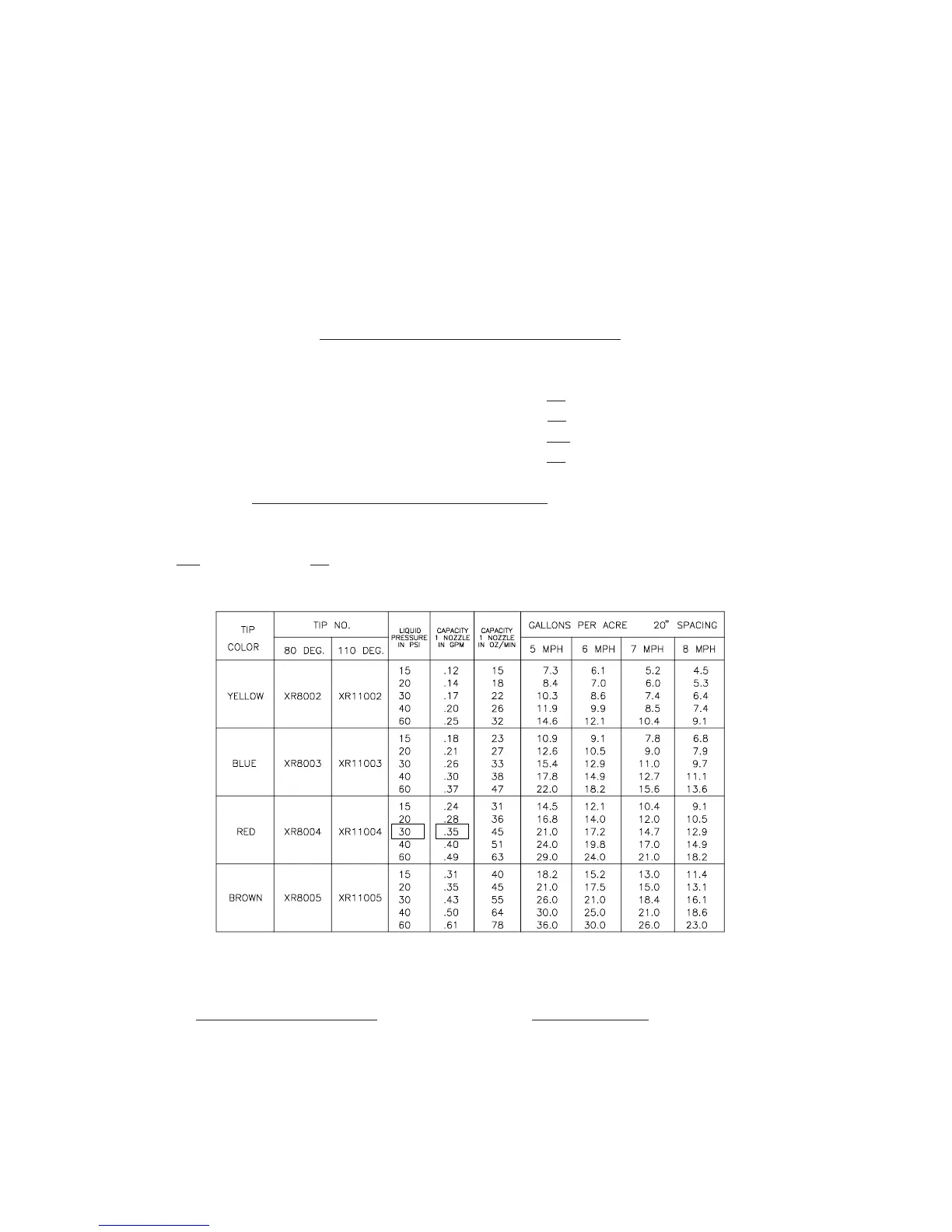

Determine the application rate at which chemical is to be sprayed. Consult with a dealer to ensure

these spray nozzles are capable of applying at this rate. In determining which spray nozzles to use

with the sprayer the following must be known:

1) Nominal Application Pressure ___ PSI [kpa]

2) Target Application Rate ___ GPA [lit/ha]

3) Target Speed ___ MPH [km/h]

4) Nozzle Spacing ___ inches [cm]

From this information, calculate the volume per minute, per nozzle as follows:

GPM [lit/min] = GPA [lit/ha] x MPH [km/h] x inches [cm]

5,940 [60,000]

EXAMPLE: 1) Application Pressure =

30 PSI

2) Target Application Rate = 20 GPA

3) Target Speed =

5.2 MPH

4) Nozzle Spacing = 20 inches

GPM = 20 GPA x 5.2 MPH x 20 inches = .35

5,940

Using GPM .35 and pressure 30 select tip number XR8004 from the chart below, since it comes closest

to providing the desired output.

V

ERIFYING FLOW RATE LIMITS:

The flow rate of spraying must be within the range of that specified for the Flow Meter included.

FLOW METER MODEL FLOW RANGE

RFM 5 0.05-5 GPM [0.2-18.9 lit/min]

RFM 15 0.3-15 GPM [1.1-56.8 lit/min]

RFM 60P 1-60 GPM [3.8-210 lit/min]

RFM 100 3-100 GPM [11.4-380 lit/min]

RFM 200/200 Poly 15-200 GPM [56.8-760 lit/min]

RFM 400 25-400 GPM [94.6-1515 lit/min]

Loading...

Loading...