92

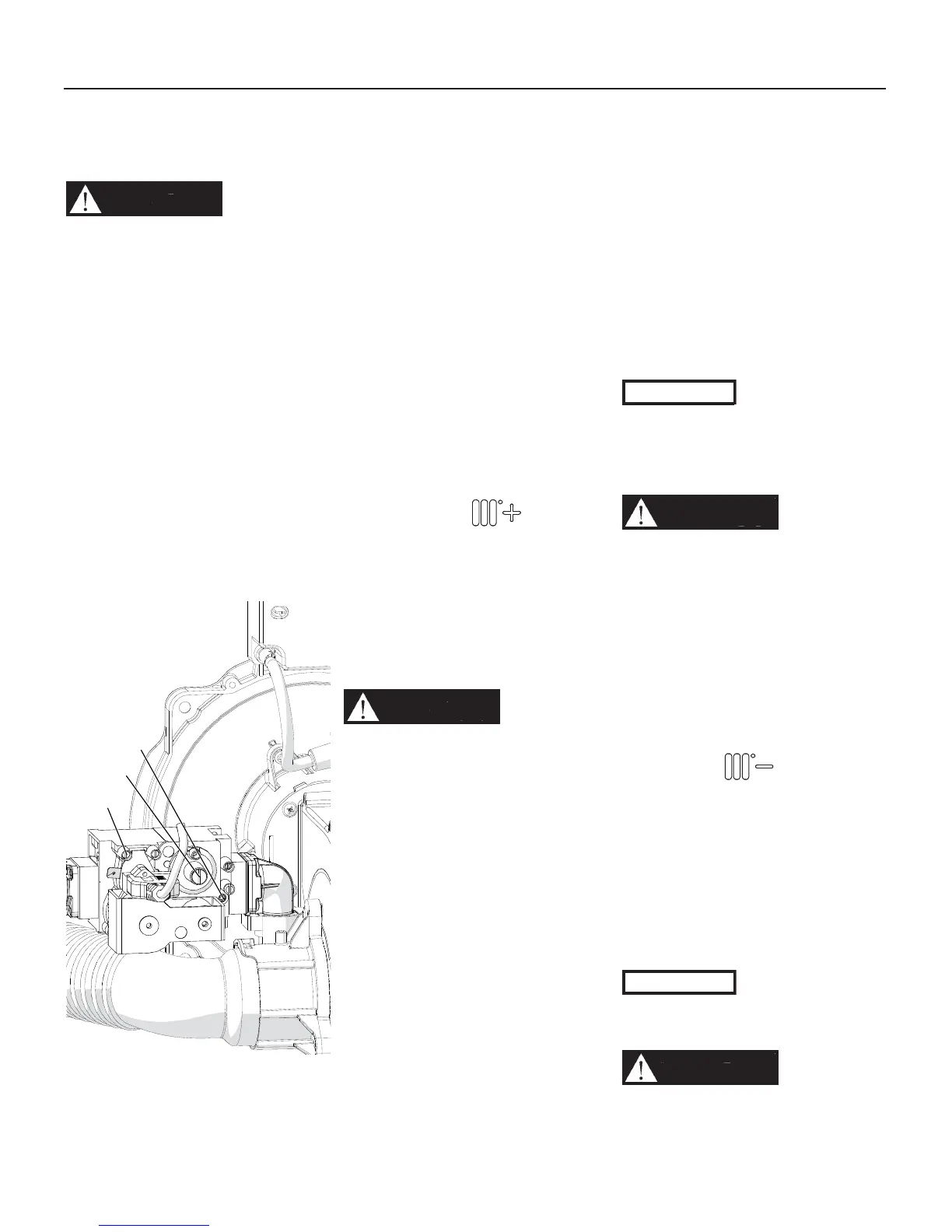

Figure 13-1 Gas valve

D - Inlet gas pressure

probe

E - CO2 adjusting screw

F - Factory adjusted

regulator (Should never

be touched)

13.7 - Gas supply

pressure checking

WARNING!!!

DO NOT

adjust or attempt to measure

gas valve outlet pressure.

The

gas valve is factory-set for the

correct outlet pressure. This

setting is suitable for natural

gas and propane, requiring no

fi eld adjustment. Attempting to

alter or measure the gas valve

outlet pressure could result

in damage to the gas valve,

causing

excessive levels of

carbon monoxide, which can

result in severe personal injury

or death!

Check the gas supply pressure by

following the steps below:

1. close the manual gas shut-off

valve, Figure 12-1;

2. follow the steps in Section 15.2 to

remove the front cover;

3. turn the screw in pressure port “D”

shown in Figure 13-1 three turns

counterclockwise;

4. connect a manometer with

graduations of at least 0.1 in.W.C.

(0.25 mbar) to the inlet gas port

“D” shown in Figure 13-1 (on unit

model 399 to 1000, choose the

pressure port “D” from any gas

valve present).

5. open the manual gas shut off valve,

Figure 12-1;

6. check that the gas supply pressure

does not exceed 13 in.W.C. If the

gas supply pressure is higher than

13 in.W.C. adjust the upstream gas

pressure regulator to bring the gas

supply pressure between 12”WC

and 13”WC;

7. turn the power switch to on and

generate a heat demand by

pressing button to its

maximum setting. Also ensure that

the room thermostat is calling for

heat and operate downstream the

13 - START-UP

E

D

F

020010.01.022

unit to verifi y the system is able to

dissipate all heat generated.

8. give 3 minutes to each heat

exchanger to reach the maximum

capacity. Check parameters 1120

up to 1123 (Section 14.13) to see

the modulating level. Must be at

100% per each heat exchanger.

9. check the manometer to make sure

the gas supply pressure does not

drop below 3 in.W.C. (7.6 mbar).

If the gas supply pressure is lower

than 3 in.W.C. means that your

inlet gas line or your gas pressure

regulator are not correctly sized;

CAUTION!!!

Do not attempt

to adjust your upstream gas

pressure regulator. This

was already adjusted for the

maximum inlet gas pressure.

WARNING!!!

DO NOT

adjust the screws “E” and/or

“F” (Figure 13-1). These screws

are factory-set for the correct

gas fl ow and outlet pressure.

Attempting to alter the gas

valve setting could result in

damage to the valve, causing

potential severe personal

injury, death, or substantial

property damage.

After verifying the correct gas

pressures:

1. push button up to see OFF

word on Display to bring the unit

into stand-by;

2. close the manual gas shut-off

valve, Figure 12-1;

2. disconnect the manometer;

3. turn the screw in pressure

connection “D” in Figure 13-1,

clockwise until snug;

4 check pressure port “D” (Figure 13-

1) for any gas leaks.

CAUTION!!!

Never force the

pressure connection screw or

the gas valve will be damaged!

WARNING!!!

Never use an

open fl ame to check for gas

leaks, a fi re or an explosion

could result causing severe

personal injury or death!

WARNING!!!

DO NOT

adjust the screws “E” and/or

“F” (Figure 13-1). These screws

are factory-set for the correct

gas fl ow and outlet pressure.

Attempting to alter the gas

valve setting could result in

damage to the valve, causing

potential severe personal

injury, death, or substantial

property damage.

Loading...

Loading...