SAM 400 SPEED-AREA-DISTANCE METER

13

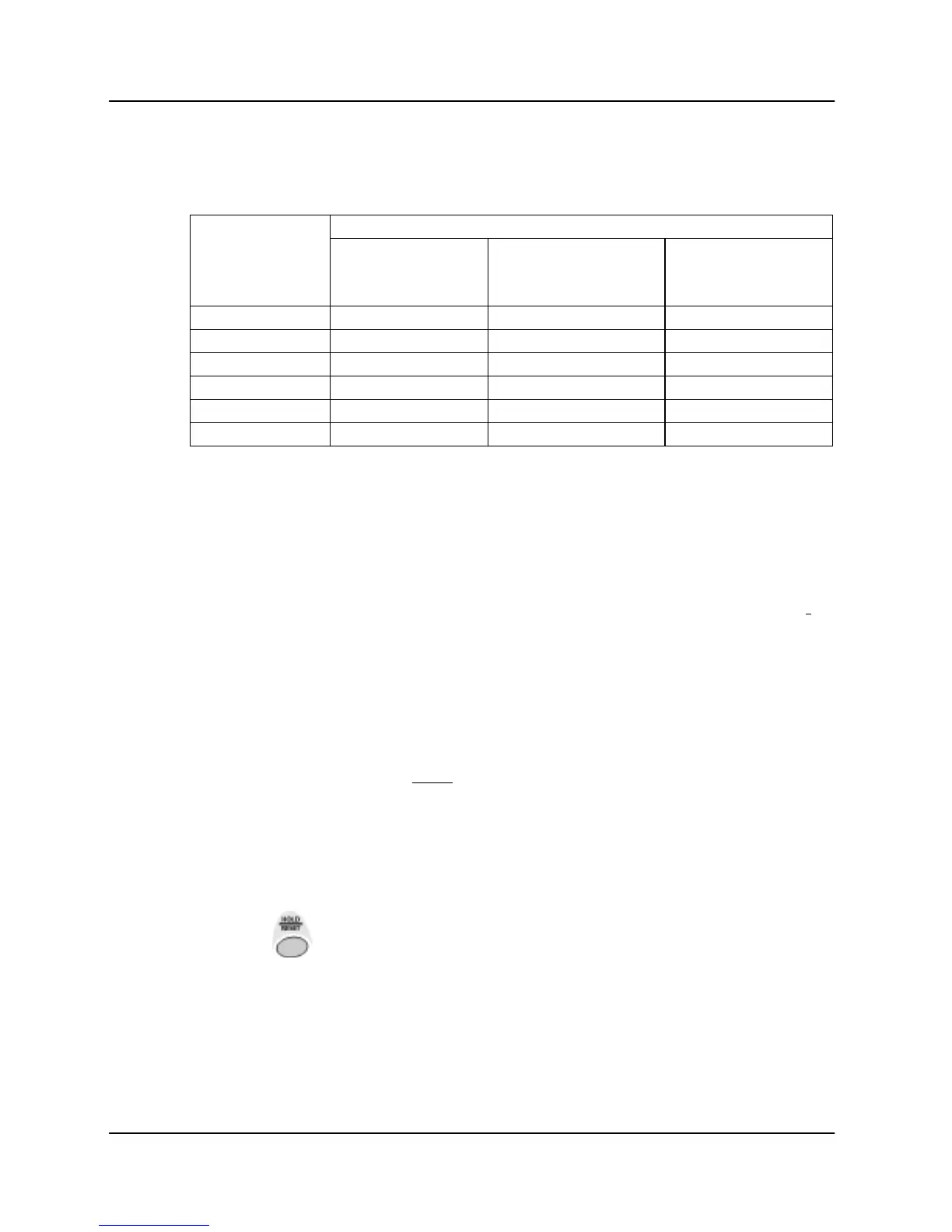

Number of Sensor magnets

The table gives the number of magnets required to enable a speed update of

approximately once per second or faster on the display.

Typical speed in normal operation:

Tyre diameter

up to 5mph

(8km/hr)

6 to 9 mph

(9 to 15 km/hr)

10mph

(16 km/hr)

or over

12" (0.3m) 1 1 1

24" (0.6m) 1 1 1

36" (0.9m) 2 2 1

48" (1.2m) 4 2 2

60" (1.5m) 4 4 2

72" (1.8m) 4 4 2

Example Calculation 1

The tractor is fitted with a single-magnet propshaft sensor. The measured

distance for 10 rotations of the propshaft is 17'-6".

1. Convert the distance to inches :- (17' x 12")+6" = 210"

2. Divide by 10 (magnet pulses) to give the calibration factor:- 210" / 10 = 21"

3. Programme the factor '021.0' as described overleaf.

Example Calculation 2

A vehicle with row crop wheels is fitted with 4 magnets. It is found to move

144 feet for 10 rotations of the sensed wheel.

Converting the distance to inches and dividing by 40 gives a calibration

factor of (144' x 12") / 40 =43.2".

Manually setting the Factor

1. Press and hold the CAL button while switching the instrument on.

2. Press the key to toggle the display to "SSF" .

3. Use the small left and right buttons to adjust the factor as required.

Loading...

Loading...