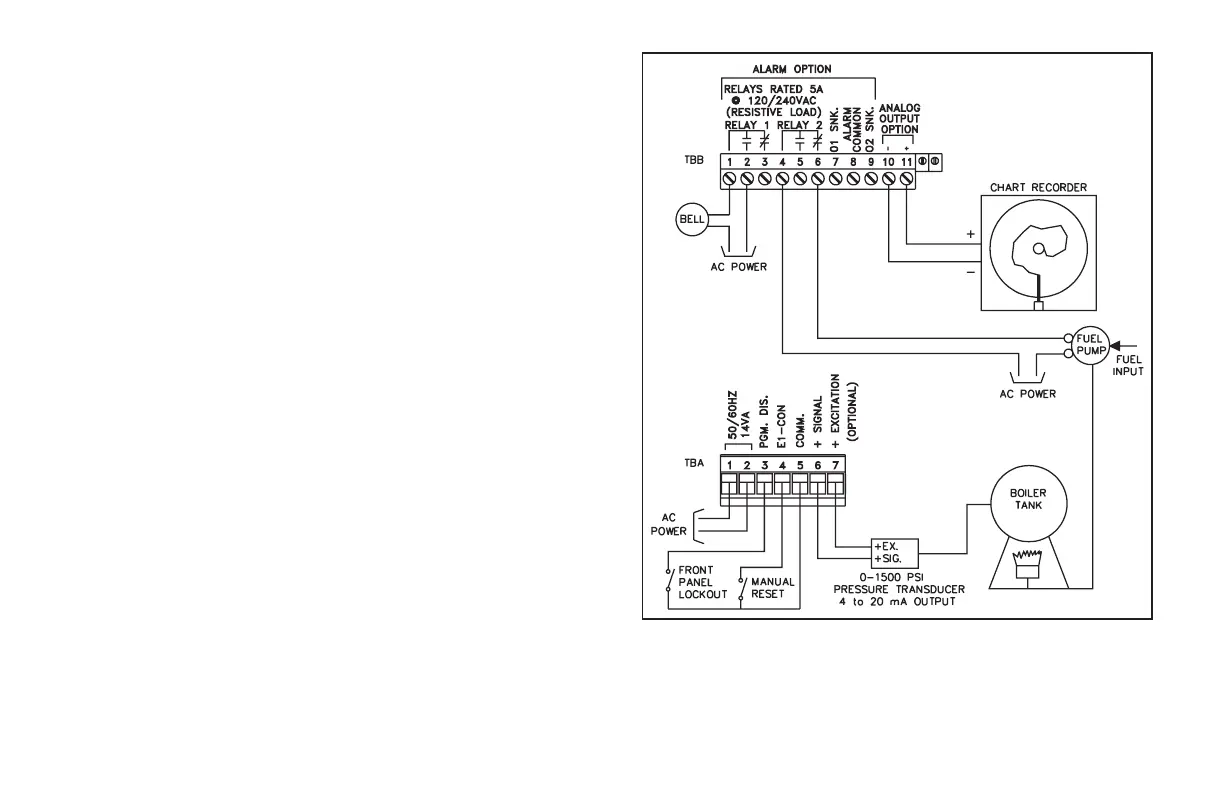

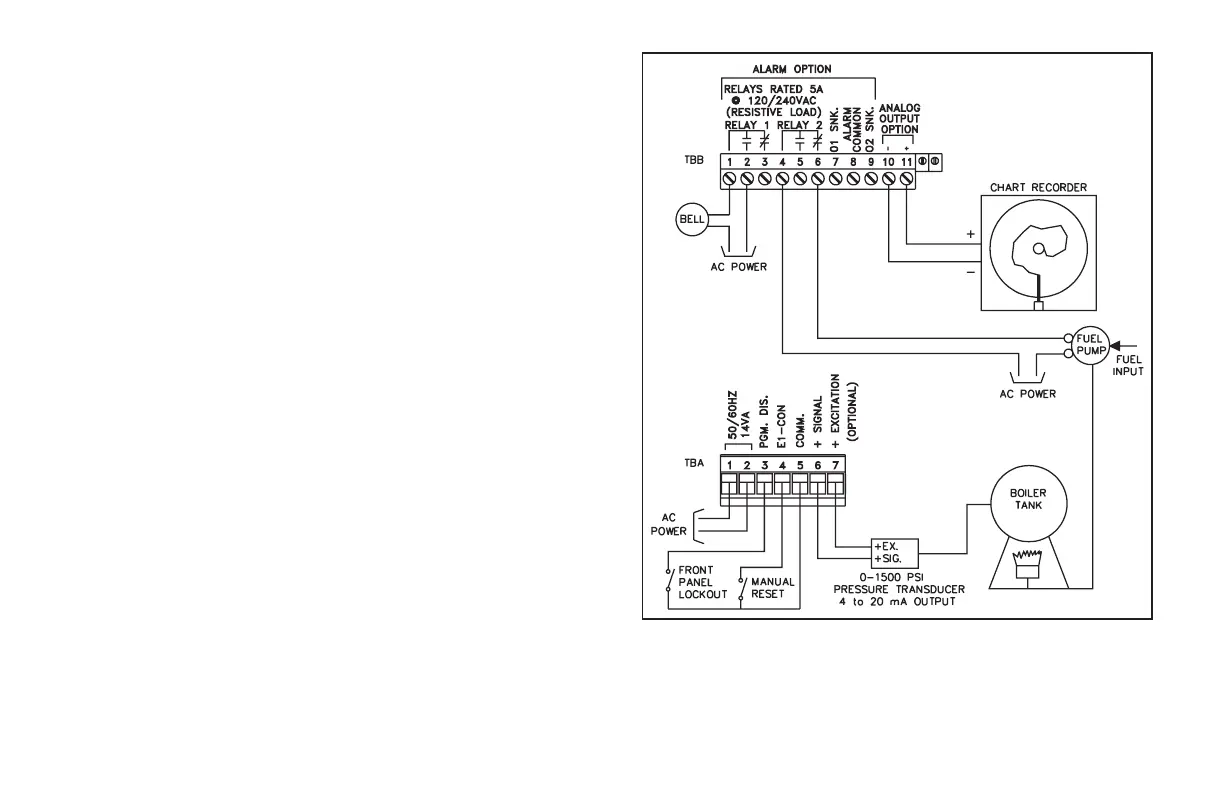

PRESSURE MONITORING EXAMPLE

An IMP indicator is installed as a monitoring device for pressure levels within

an industrial boiler. A pressure transducer with a range of 0-1500 PSI and a

corresponding 4 to 20 mA output is selected. The maximum allowable pressure

of the boiler is 1200 PSI, at which time a pressure relief valve will operate (this

makes the system inherently safe). In addition, when the relief valve trips, fuel

delivery to the boiler must be stopped. The relay option of the indicator is

employed to turn off the fuel at 1200 PSI. To provide for fail safe operation,

operator intervention is required to reset the latched relay in order to re-start the

boiler. The indicator’s other output is used to signal operators with a warning bell

when high pressures exist (1100 psi), so that they may take action to prevent

boiler shut-down. The alarm/setpoint values are set up for tracking, so changing

the cut-off alarm value changes the other alarm value an equal amount. The

indicator is programmed to provide a display of active alarms in both cases. Key

switches are installed in the panel to lock-out the front panel from operators and

to provide the means to reset the latched relay to re-start the boiler. The

linearizer/totalizer option is specified to integrate the average boiler pressure

over discrete time periods (ie. overnight, during peak use, start-up, etc). Peak

pressures are automatically stored with this option. Programming module #5

(Pro 5) is used to set up the integrator. The re-transmitted analog output is also

specified to drive a chart recorder with 4 to 20 mA for a hard copy of pressure

profiles for later evaluation.

Scaling of the indicator is done by programming module #1 (Pro 1). For dSP 1,

0 PSI is keyed-in. For INP 1, the transmitter is powered and connected to the

indicator and the boiler is at 0 PSI. The indicator then measures the output from

the transmitter. For dSP 2, 1000 PSI is keyed-in. Prior to INP 2, the boiler is fired

and brought to 1000 PSI as checked by a reference pressure gage. Once

stabilized, the indicator is allowed to measure the output of the transducer for

INP 2. Since there are no span/zero interactions, scaling is complete.

-23-

Loading...

Loading...