Description of the device

Vacuum spray degassing — 06.07.2016 - Rev. B English —

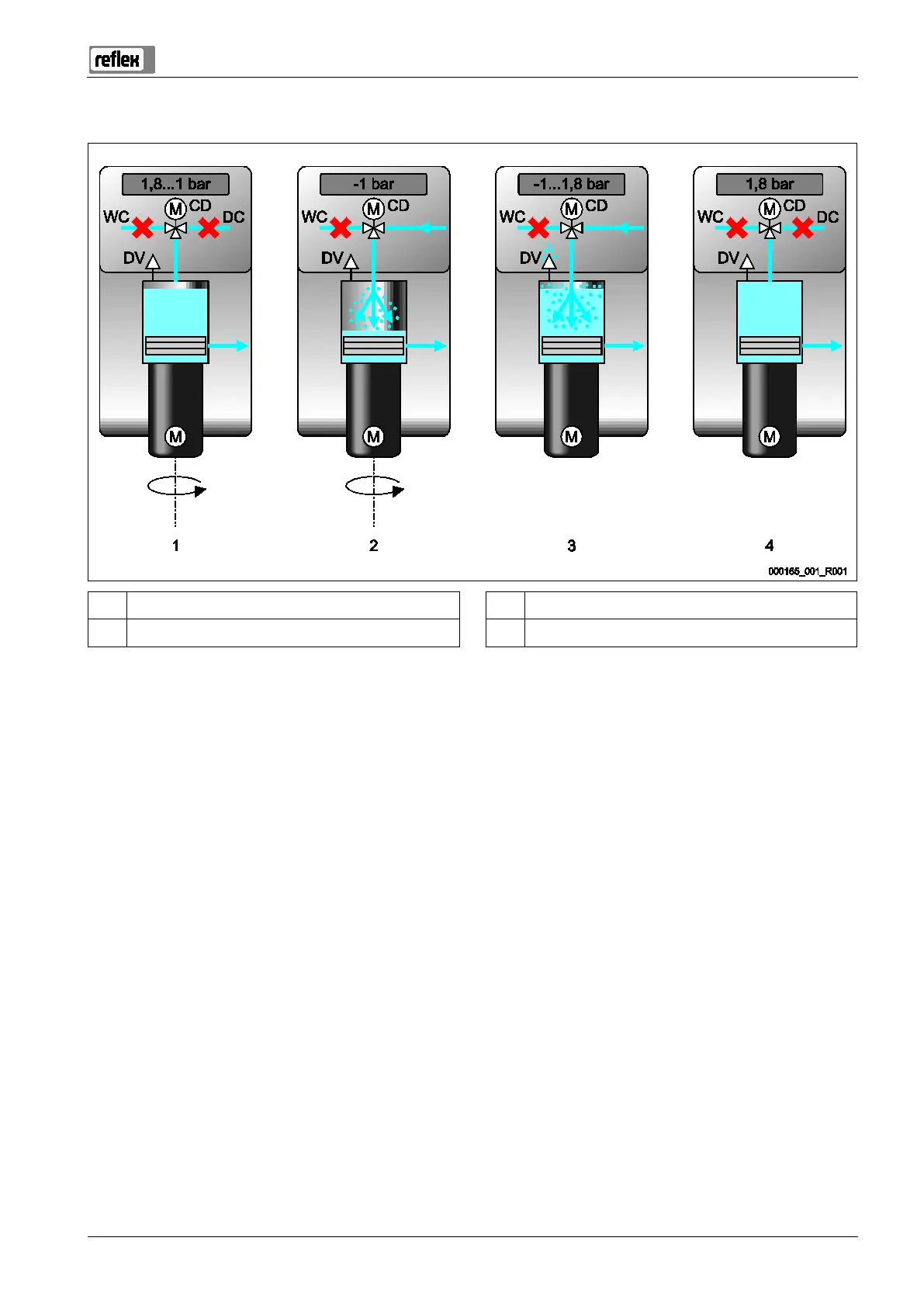

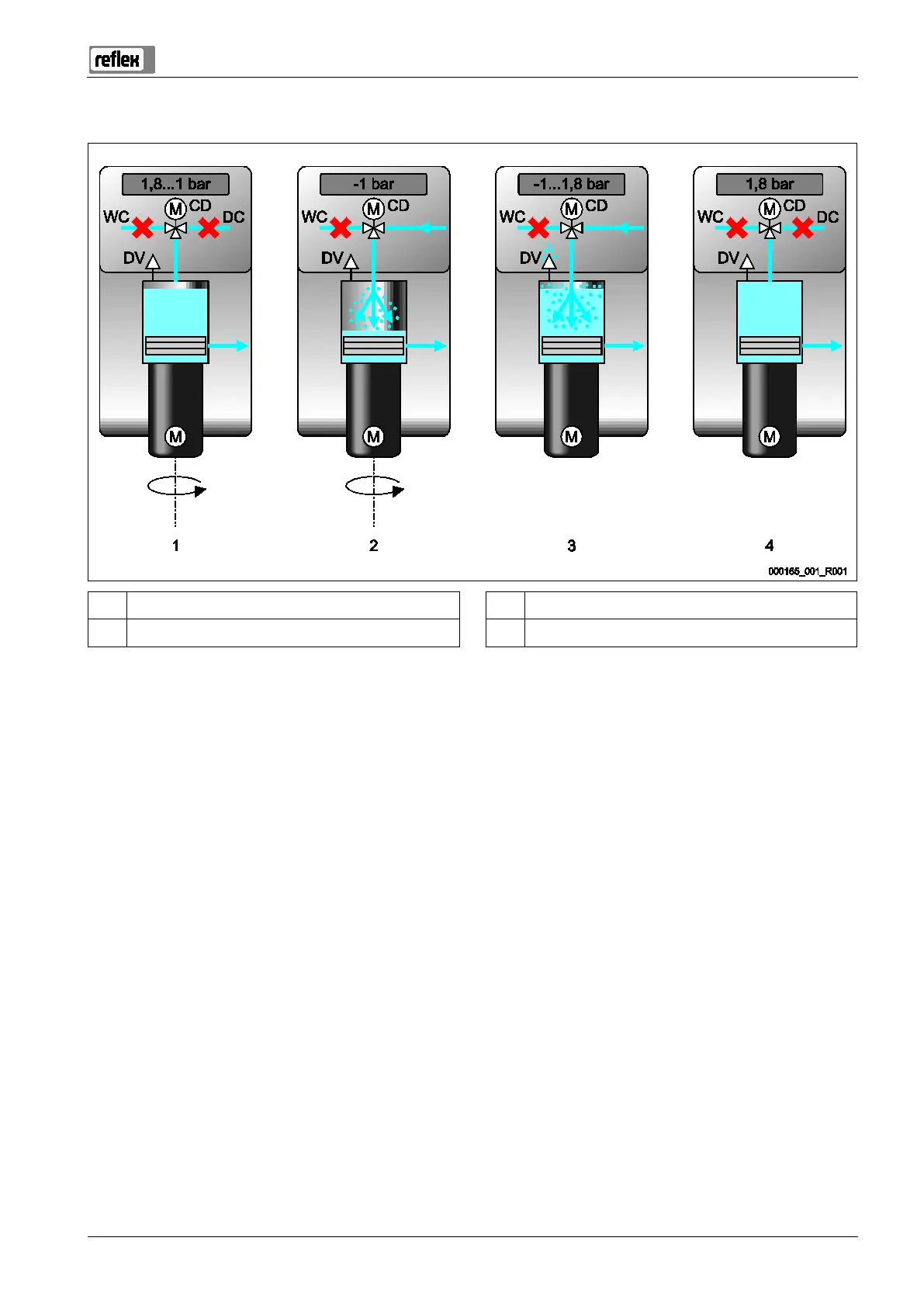

Degassing cycle sequence in the PU vacuum pump

Cooling water system ≤ 30 °C, System pressure 1.8 bar, "DC" system degassing in operation, "WC" make-up degassing closed.

1 Vacuum is drawn 3 Discharge

2 Atomisation 4 Idling time

The entire degassing process is hydraulically synchronised by the "CD" 3-ways motor ball valve and the device controller. The system

monitors the operating states and displays them at the controller. The controller provides 3 different degassing programmes and 2

different make-up variants for selection and setting.

For continued degassing over several hours or days in a seque

nce of degassing cycles without idling

This programme is recommended after commissioning and repairs.

Interval degassing comprises a limited number of degassing cycles. The system idles between the intervals.

This programme is

recommended for continuous operation.

-up degassing:

-up degassing automatically activated for every water make-up during continuous or interval

degassing. The process is the same as in continuous degassing. The degassing time is limited by the m

ake-

Loading...

Loading...