Vacuum spray degassing — 06.07.2016 - Rev. B English —

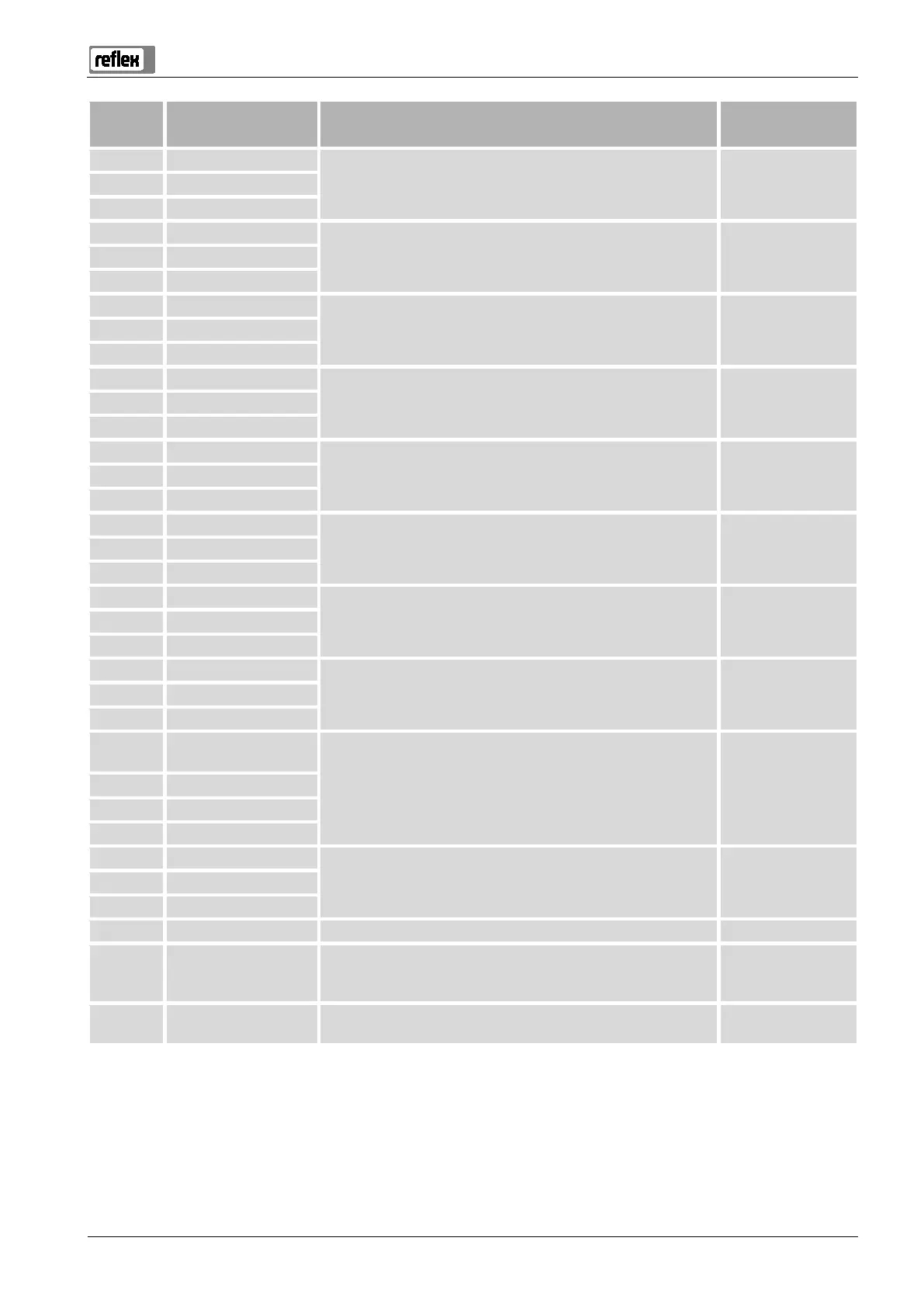

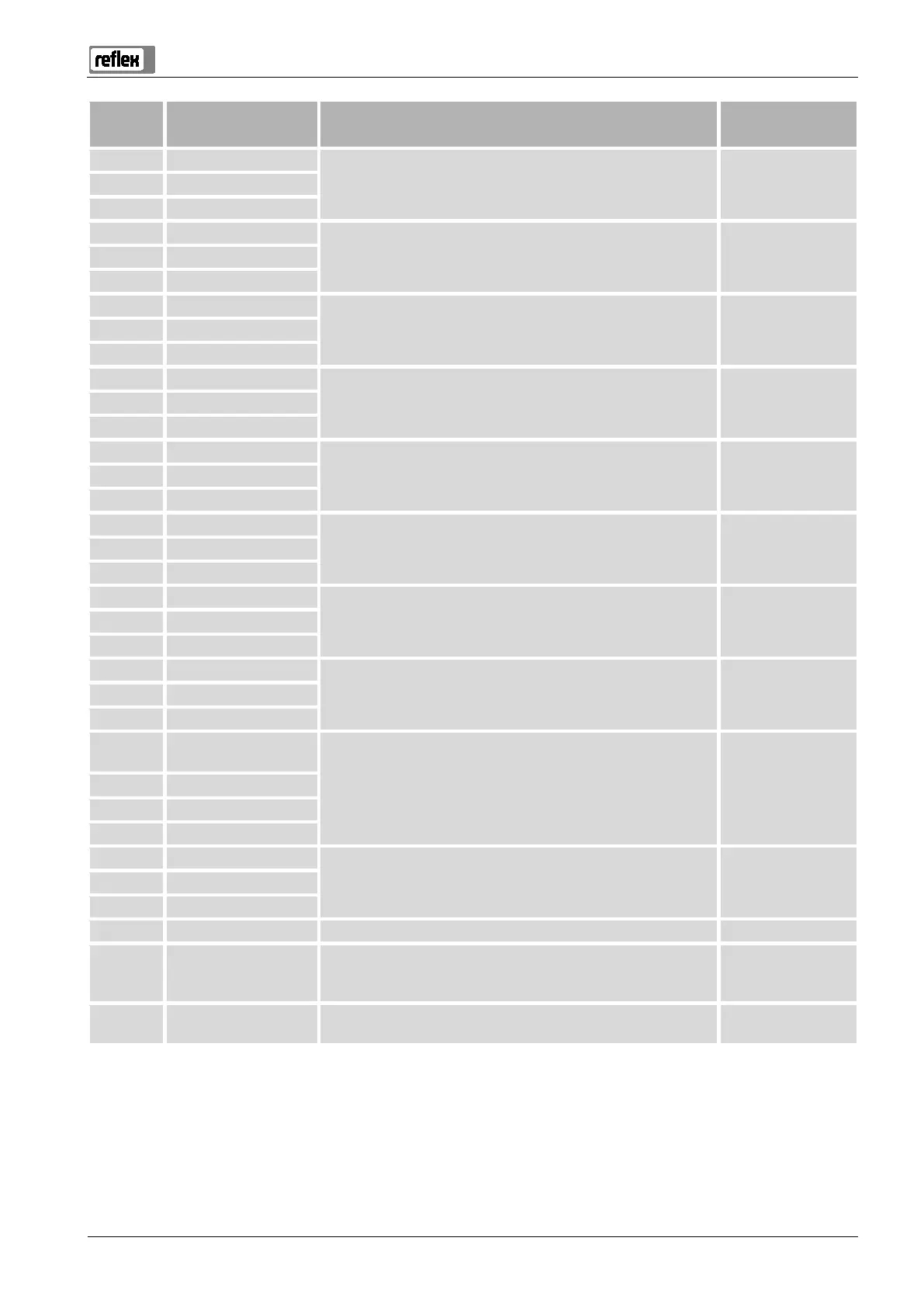

1 PE

230 V power supply via mains cable and plug. Pre-wired 2 N

3 L

4 PE

"PU" vacuum pump for degassing. Pre-wired 5N N

6 M1 M 1

7 Y2

Overflow solenoid valve

Not used in standard model

--- 8 N

9 PE

10 Y 1

"CD" 3-

ways motor ball valve for regulating the degassing of makeup

and system water.

Pre-wired 11 N

12 PE

13 COM

Group message (floating). User, optional 14 NC

15 NO

16 Not assigned

External makeup demand from a pressurisation station; controller

must be set to "Levelcontrol"!

User, optional 17 Makeup (230 V)

18 Makeup (230 V)

19 PE shield

Level analogue input, not used by the device. --- 20 - Level (signal)

21 + Level (+ 18 V)

22 PE (shield)

Pressure analogue input for display and makeup; controller must be

set to "Magcontrol"!

Pre-wired 23 - Pressure (signal)

24 + Pressure (+ 18 V)

25 0 – 10 V (correcting

variable)

"CD" 3-ways motor ball valve, not used with the device. ---

26 0 – 10 V (feedback)

27 GND

28 + 24 V (supply)

29 A

RS-485 interface. User, optional 30 B

31 GND

32 + 24 V (supply) E1 Supply for E1 and E2. Pre-wired, bridged

33

E1 Contact water meter, for example in Fillset, see chapter 4.6 "Optional

equipment and accessories" on page 13 , for makeup evaluation,

contact 32/33 closed = meter pulse.

User, optional

34

E2 Insufficient water switch, not used with the device, contact 32/34

closed = OK.

Pre-wired, bridged

Loading...

Loading...