— English Variomat 1 — 06.07.2016 – Rev. B

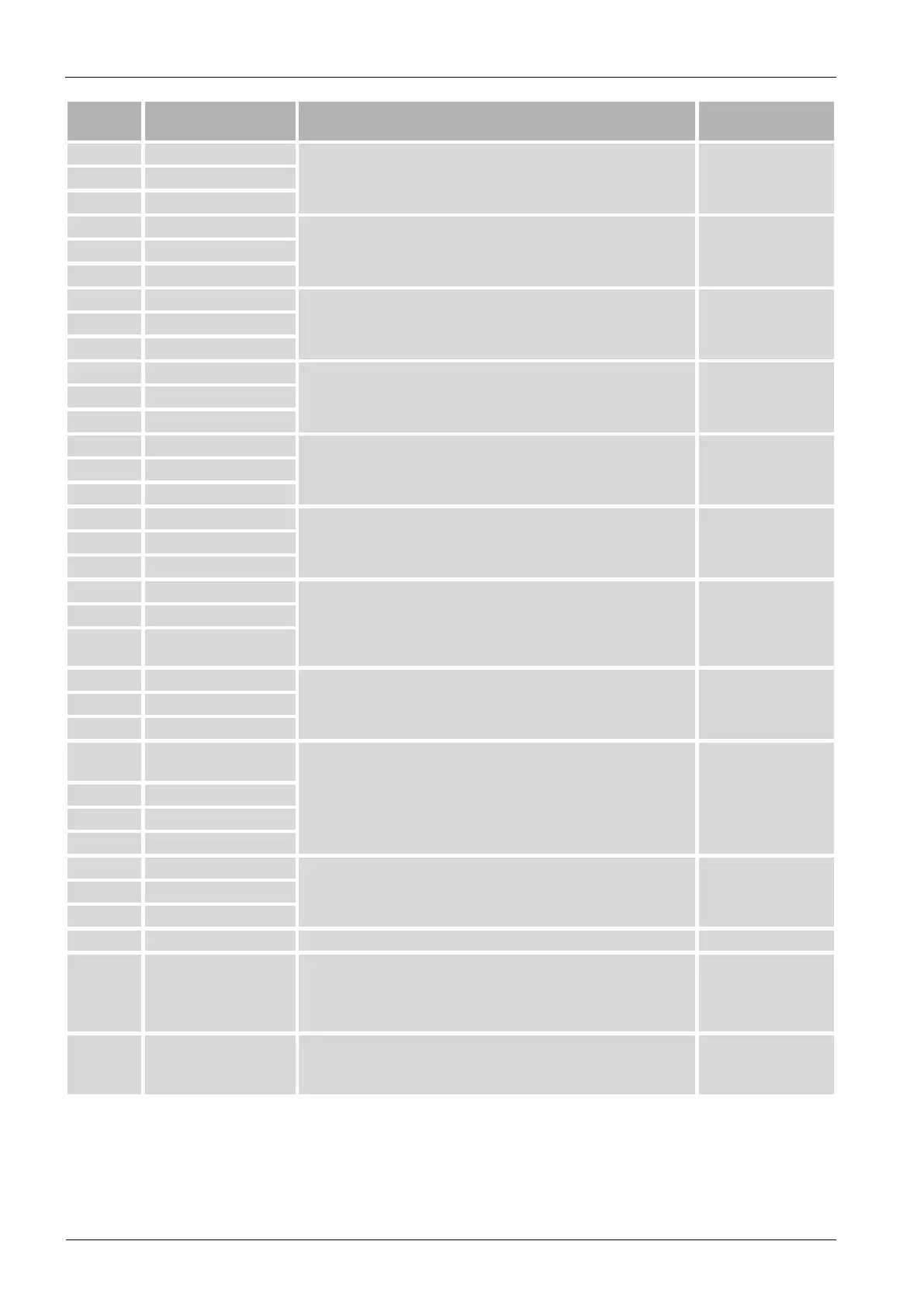

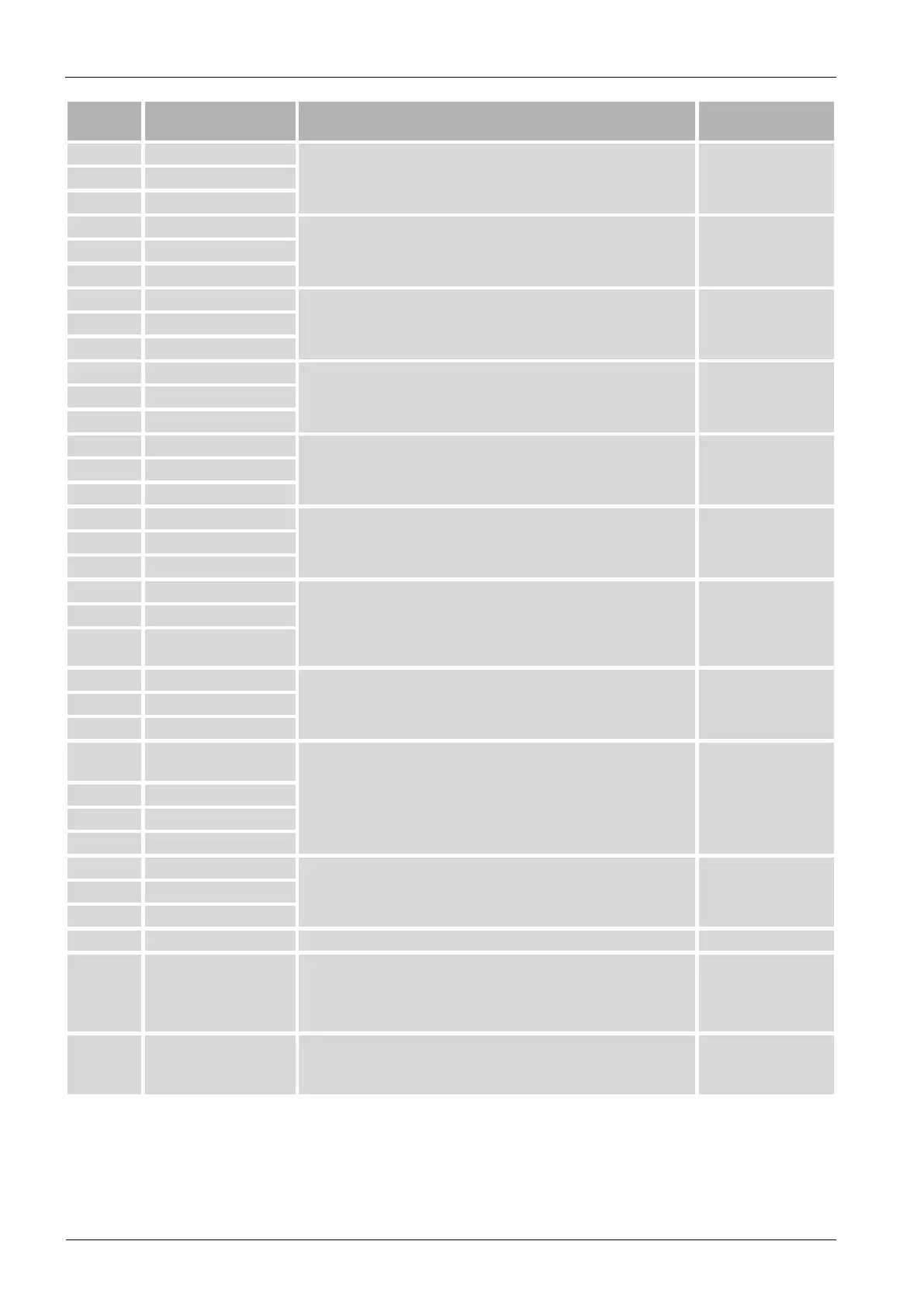

1 PE

230 V power supply via mains cable and plug. Pre-wired 2 N

3 L

4 PE

Pump for maintaining the pressure. Pre-wired 5N N

6 M1 M 1

7 Y2

Overflow solenoid valve

• Not used in a standard device.

--- 8 N

9 PE

10 Y 1

Valve to control the water make-up. Pre-wired 11 N

12 PE

13 COM

Group message (floating). User, optional 14 NC

15 N.O.

16 Not assigned

External make-up request.

• To be used only upon consultation with the Reflex Customer

Service.

--- 17 Make-up (230 V)

18 Make-up (230 V)

19 PE shield

Level analogue input.

• Display at the controller.

• Activation of the make-up.

• Dry-running protection of the pump.

Factory prepared,

sensor plug must be

inserted on site

20 - Level (signal)

21 + Level (+ 18 V)

22 PE (shield)

Pressure analogue input.

• Display at the controller.

• Control of pressure maintenance.

Pre-wired 23 - Pressure (signal)

24 + Pressure (+ 18 V)

25 0 – 10 V (correcting

variable)

Motor ball valve in the overflow line to control the pressure

maintenance.

Pre-wired

26 0 – 10 V (feedback)

27 GND

28 + 24 V (supply)

29 A

RS-485 interface. User, optional 30 B

31 GND

32 + 24 V (supply) E1 Supply for E1 and E2. Pre-wired

33

E1 Contact water meter (in Fillset, for example), see chapter 4.6

"Optional equipment and accessories" on page 13 .

• Evaluation of the make-up.

– If contact 32/33 is closed = meter pulse.

User, optional

34

E2 Insufficient water switch.

• Not used in this device.

– If contact 32/34 is closed = OK.

---

Loading...

Loading...