— English Variomat 1 — 06.07.2016 – Rev. B

Note!

Confirm that installation and start

-up have been carried out correctly using the installation, start-up and maintenance

certificate. This action is a prerequisite for the making of warranty claims.

Have the Reflex Customer Service carry out commissioning and the annual maintenance.

Checking the requirements for commissioning

The device will be ready for commissioning when the tasks described in the "Installation" chapter have been completed. The system

designer or an assigned expert is responsible for carrying out the commissioning. Commission the storage tank according to the

information in the corresponding installation manual. Note the following information on commissioning:

• The control unit is connected to the primary tank and the secondary tanks, if provided.

• The water connections of the tanks to the facility system are established.

• The tanks are not filled with water.

• The valves for emptying the tanks are open.

• The facility system is filled with water and gas-vented.

• The electrical connection has been created according to applicable national and local regulations.

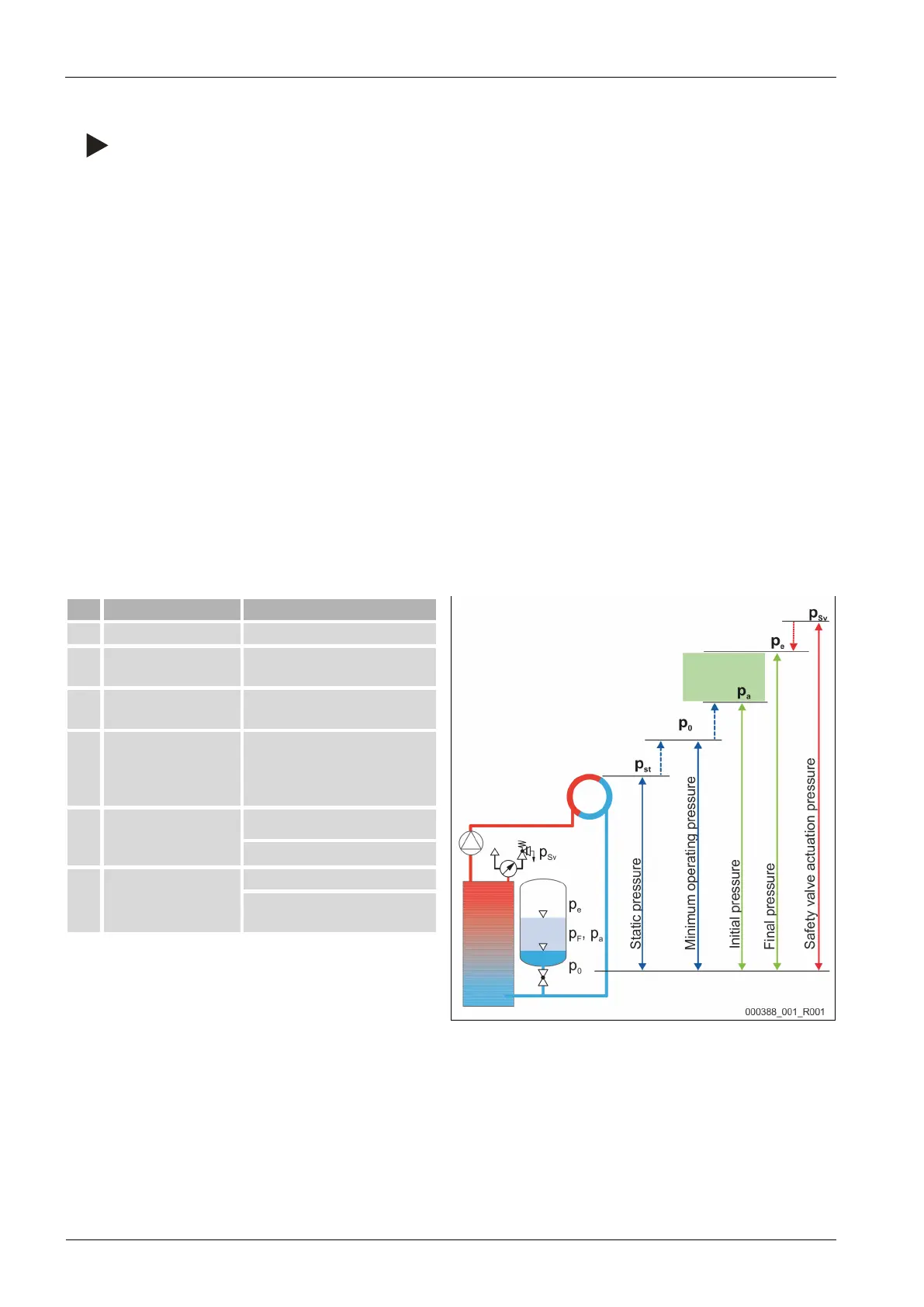

Determining the P

0

minimum operating pressure for the controller

The "p

0

" minimum operating pressure is determined by the location of the pressure maintaining device. The controller calculates the

switching points for the "PV" overflow solenoid valves and the "PU" pumps from the minimum operating pressure.

p

st

Static pressure = static head (h

st

)/10

p

0

Minimum operating

pressure

p

a

Initial pressure (pump

"ON")

= p

0

+ 0.3 bar

Static pressure

(overflow solenoid

valve "CLOSED" /

Pump "OFF")

p

e

Final pressure

(overflow solenoid

valve "OPEN")

≤ p

Sv

- 0.5 bar (for p

Sv

≤ 5.0 bar)

≤ p

Sv

x 0.9 (for p

Sv

> 5.0 bar)

p

Sv

Safety valve actuation

pressure

= p

0

+ 1.2 bar (for p

Sv

≤ 5.0 bar)

= 1.1 x p

0

+ 0.8 bar

(for p

Sv

> 5.0 bar)

Loading...

Loading...