11

6.4 CONNECTING DRAIN LINE

For all evaporators, a drain line union is recommended

for ease of installation and future servicing and should be

located in close proximity to the drain pan.

EK, LM, LJ & DJ: A 7/8" ID removable drain coupling is

supplied with each unit.

EM & EJ are supplied with 1 1/4" FPT connections.

FOR ALL MODELS, connect the drain line as follows:

1. Replace the rubber gasket to prevent condensate

leakage.

2. Locate the union as close to the drain pan as possible.

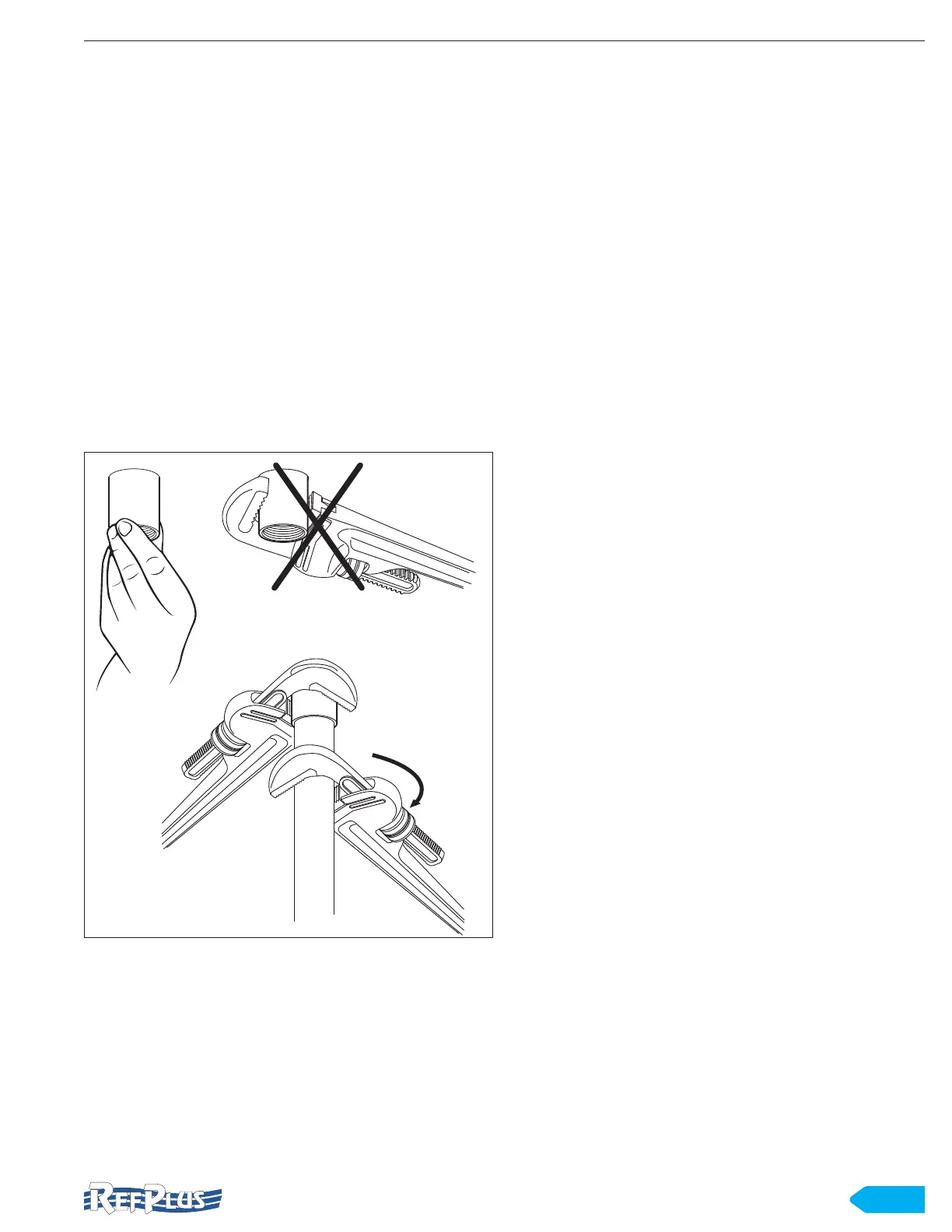

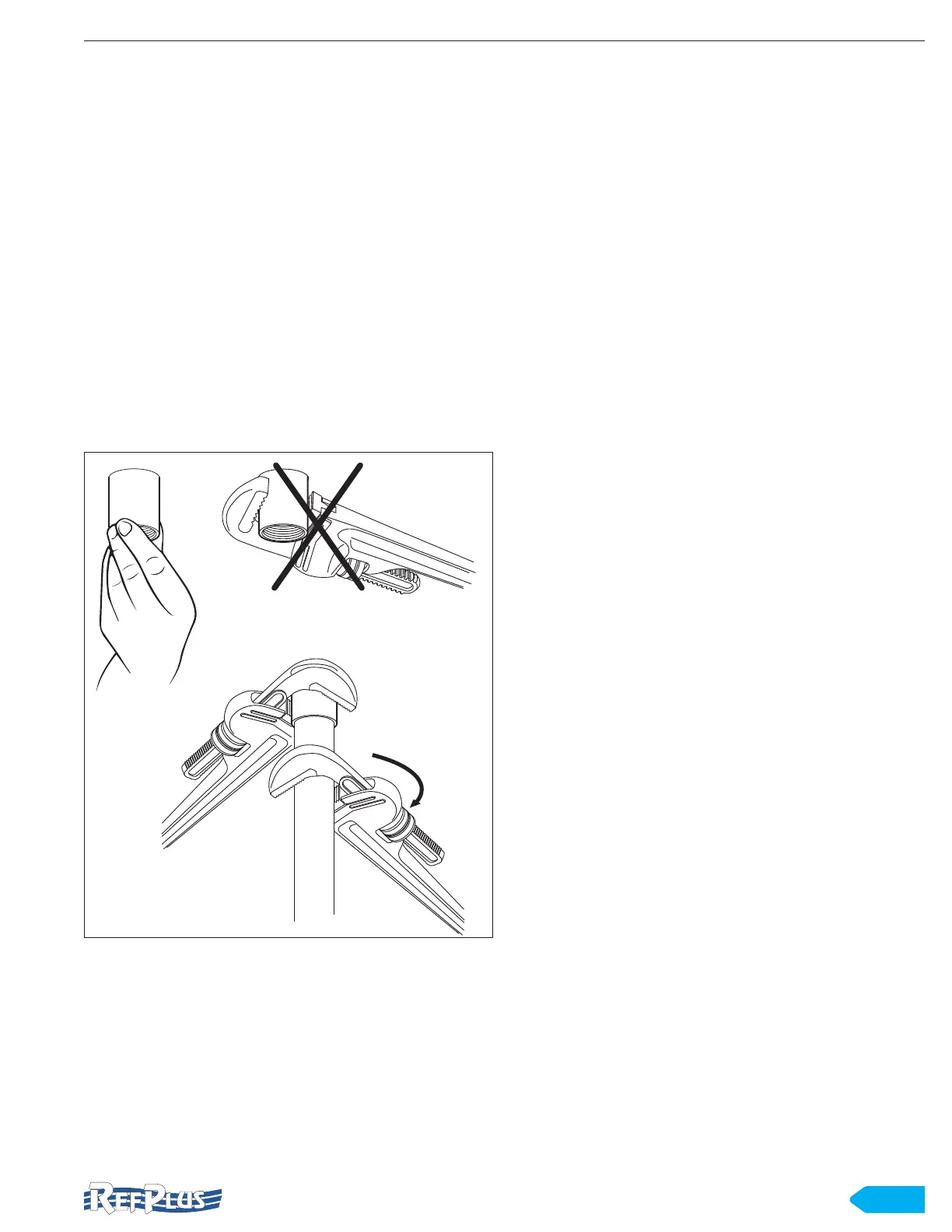

3. Hand tighten the coupling as shown in Figure 4. DO

NOT use wrench to tighten coupling in place as this

could damage the gasket and cause leaks. Once the

coupling is in place, connect the drain pipe and tighten

pipe using two wrenches as shown. The use of two

wrenches will prevent the coupling from twisting and

damaging the unit.

HAND TIGHTEN ONLY

LOCK COUPLING IN PLACE

WHILE TIGHTENING PIPE

Figure 4 Drain pan coupling

4. Sharply pitch the drain line and exit it through the

cooler with a short run.

5. Insulate and seal the drain line where it passes through

the wall.

6. Locate the drain traps in warm ambient air temperature

to prevent freeze-up.

Drain traps on low temperature units must be outside of

refrigerated enclosures. Properly protected from freezing,

copper or steel pipes should be used. Food approved plastic

can also be used for medium temperature coolers above

35°F (2°C). The drain line must have a minimum of 4’’ per foot

pitch for proper drainage. The unit must be perfectly level in

two directions. The drain line should be at least as large as

the evaporator drain connection. All plumbing connections

should be made in accordance with local plumbing codes.

All condensate drain lines must be trapped and run to an

open drain. They must never be connected directly to the

sewer system. Traps in the drain lines must be in a warm

ambiance.

We recommend a trap on each evaporator. Traps located

outside the building must be insulated and wrapped with a

drain line heater. When installing the heater, be sure to avoid

overlapping. The heater must be permanently energized. A

heat input of at least 20 W per linear foot of drain line for a

0°F (-18°C) room and 30 W per linear foot of drain line for

a -20°F (-29°C) room should be satisfactory. Always trap

drain lines individually to prevent vapour migration.

6.5 CONNECTING REFRIGERANT LINES

All refrigerant system components must be installed in

accordance with applicable local and national codes using

proper engineering practices. Refer to the piping diagrams

on page 36.

Use top quality refrigeration tubing that is internally free of

dirt, humidity or other contaminants. Unsealed tubing should

not be used. Long radius elbows are recommended.

Dry nitrogen must be swept through the lines while joints are

brazed to avoid oxidation and carbon deposits.

IMPORTANT: A calibrated pressure gauge and regulator

must always be used with nitrogen gas cylinders.

All external piping must be well supported. The unit will not

support external piping or valves.

If the condition arises where the suction line must be raised

to a point higher than the suction connection on the unit, a

suction line trap must be installed on the unit.

Horizontal suction lines should slope away from the

evaporator toward the compressor. Leak check and

evacuate the system using a two-stage deep vacuum pump.

Pull and hold for 24 hours a 500 micron vacuum.

INSTALLATION

Loading...

Loading...