6

5. HANDLING AND RIGGING

Good handling and rigging practices must be followed

to protect units from damage. Having proper handling

equipment at the job site is most important and it should be

planned.

In the US, follow OSHA 1926.251 standard for Rigging

Equipment and Material Handling.

In Canada, follow your province’s requirements for

hoisting and rigging.

Improper rigging of a load or a rigging failure

can expose riggers and other workers nearby to

a variety of potential hazards.

Always lift units secured to the fork lift to

prevent it from slipping off.

Your unit is shipped crated on a pallet. This prevents any

damage to the drain pan underneath. To fasten the unit to

the ceiling, it is recommended to leave it on the pallet in

order to securely lift it up with a motorized or hand-operated

forklift. Do not use a forklift against sheet metal panels or

coils. Make sure forks extend the entire length of the unit

and against a structural part or frame.

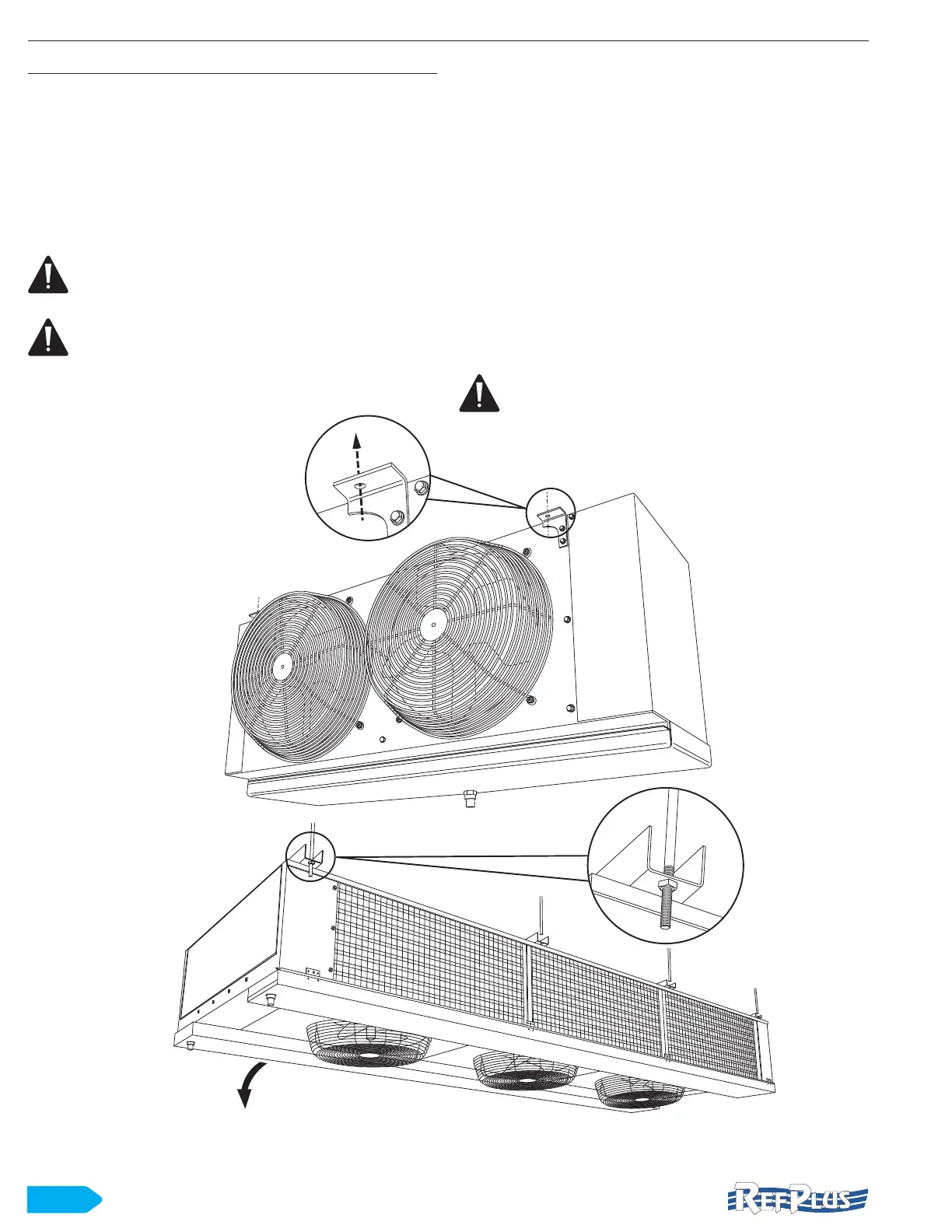

On EK models, use the provided support brackets to bolt the

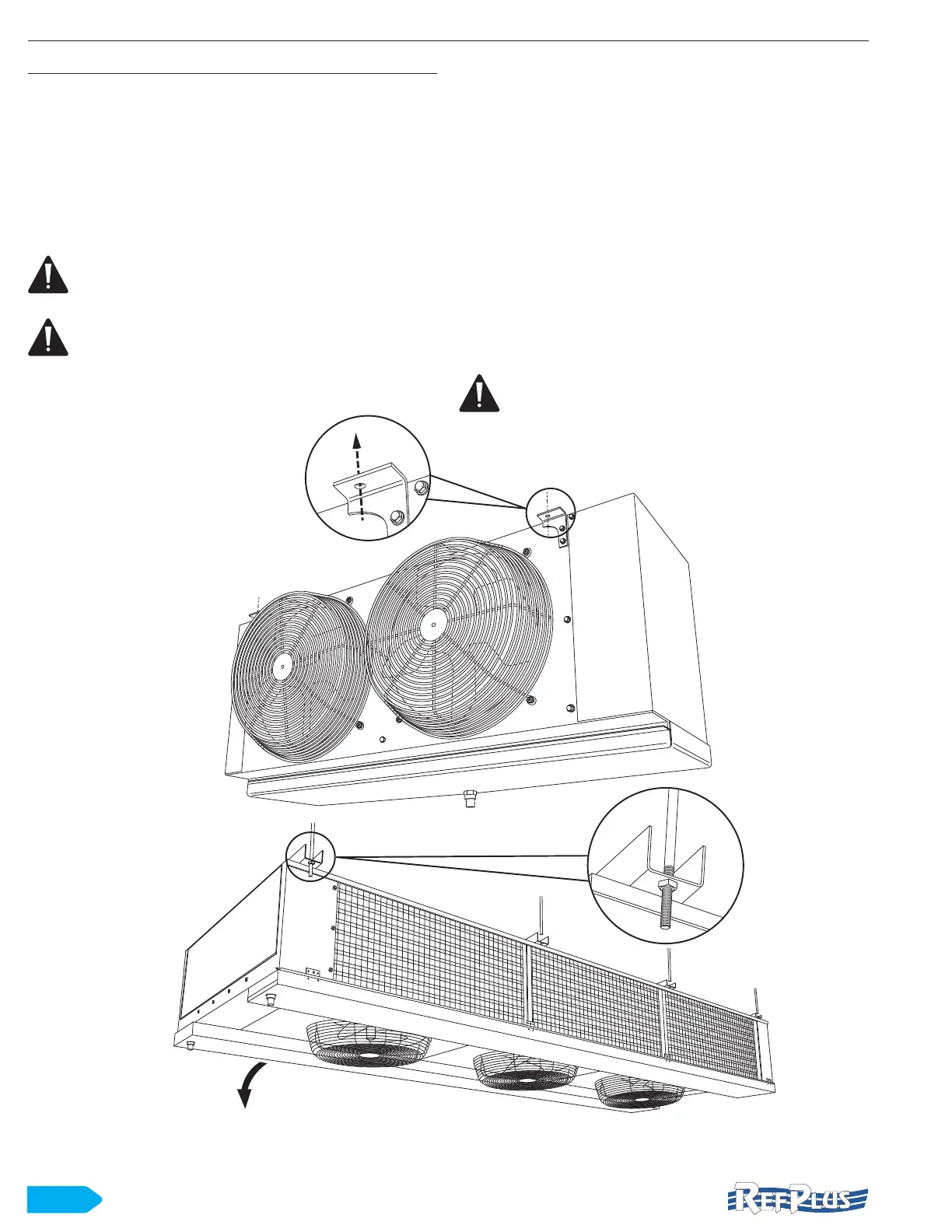

unit to the ceiling, as shown. EM, EJ, LM, LJ and DJ models

must be mounted with steel rod hangers, as shown in Figure

1. Refer to section 6.3 MOUNTING for more information.

LM, LJ and DJ units should be titled so that drain ttings are

on the lower side, to allow proper draining.

This procedure is for reference only. Rigging and handling

procedures will vary from one machine to another and from

one site to another.

Equipment handling and rigging should be

carried out by a certied operator.

LJ-DJ

EK

LM, LJ & DJ UNITS MUST BE TILTED

TO ALLOW PROPER DRAINING

Figure 1 Securing unit to ceiling

HANDLING AND RIGGING

Loading...

Loading...