12

6.6 CONNECTING THE EXPANSION VALVE

All units are supplied with a sweat expansion valve

connection. Expansion valves are eld supplied or may have

been installed at the factory (optional).

All units require the use of an externally equalized expansion

valve and are provided with a 1/4" OD equalizer line.

Check the operation of the expansion valve after the system

has reached the desired cooler temperature. If the coil is not

receiving enough refrigerant, reduce the superheat setting

on the expansion valve.

To ensure unit performance, the expansion valve must be

set at the proper superheat and at the lowest temperature in

which the system is expected to operate.

6.7 BULB LOCATION AND INSTALLATION

The location and installation of the bulb is extremely

important to the proper system performance and care

should be taken with its nal location. Accepted principles of

good suction line piping should be followed to provide a bulb

location that will give the best possible valve control.

The bulb should be securely fastened to a clean straight and

horizontal section of the suction line at the evaporator outlet.

This will ensure good thermal contact between the bulb and

the suction line for satisfactory expansion valve control. If

the bulb cannot be located in that manner, it may be located

on a descending vertical line only. The bulb should never

be located in a trap or downstream of a trap in the suction

line. Liquid refrigerant or mixture of liquid refrigerant and oil

boiling out of the trap will falsely inuence the temperature of

the bulb and result in poor valve control.

On suction lines 7/8” OD and larger, the surface temperature

may vary slightly around the circumference of the line. On

these lines, it is generally recommended that the bulb be

installed at 4 or 8 o’clock on the side of the horizontal line,

and parallel with respect to the direction of ow. On smaller

lines the bulb may be mounted at any point around the

circumference, however locating the bulb on the bottom of

the line is not recommended as an oil-refrigerant mixture

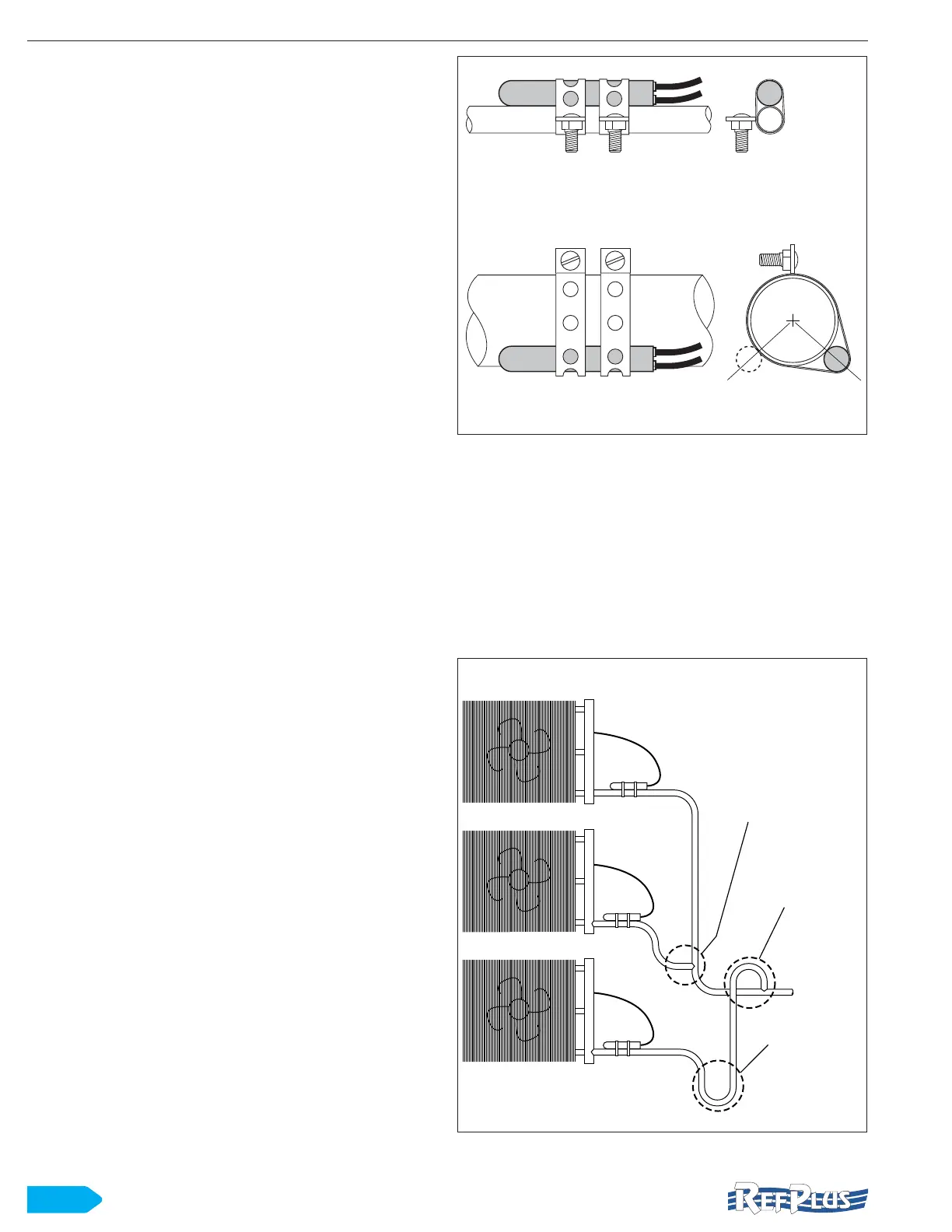

is generally present at that point. Figure 5 shows both

installation conguration. Certain conditions, specic to a

particular system, may require a different bulb location than

normally recommended. In these cases, the proper bulb

location may be determined by trial.

BULB ON SMALL SUCTION LINE

BULB ON LARGE SUCTION LINE

7/8” OD AND LARGER

8 o’clock 4 o’clock

Figure 5 Bulb installation

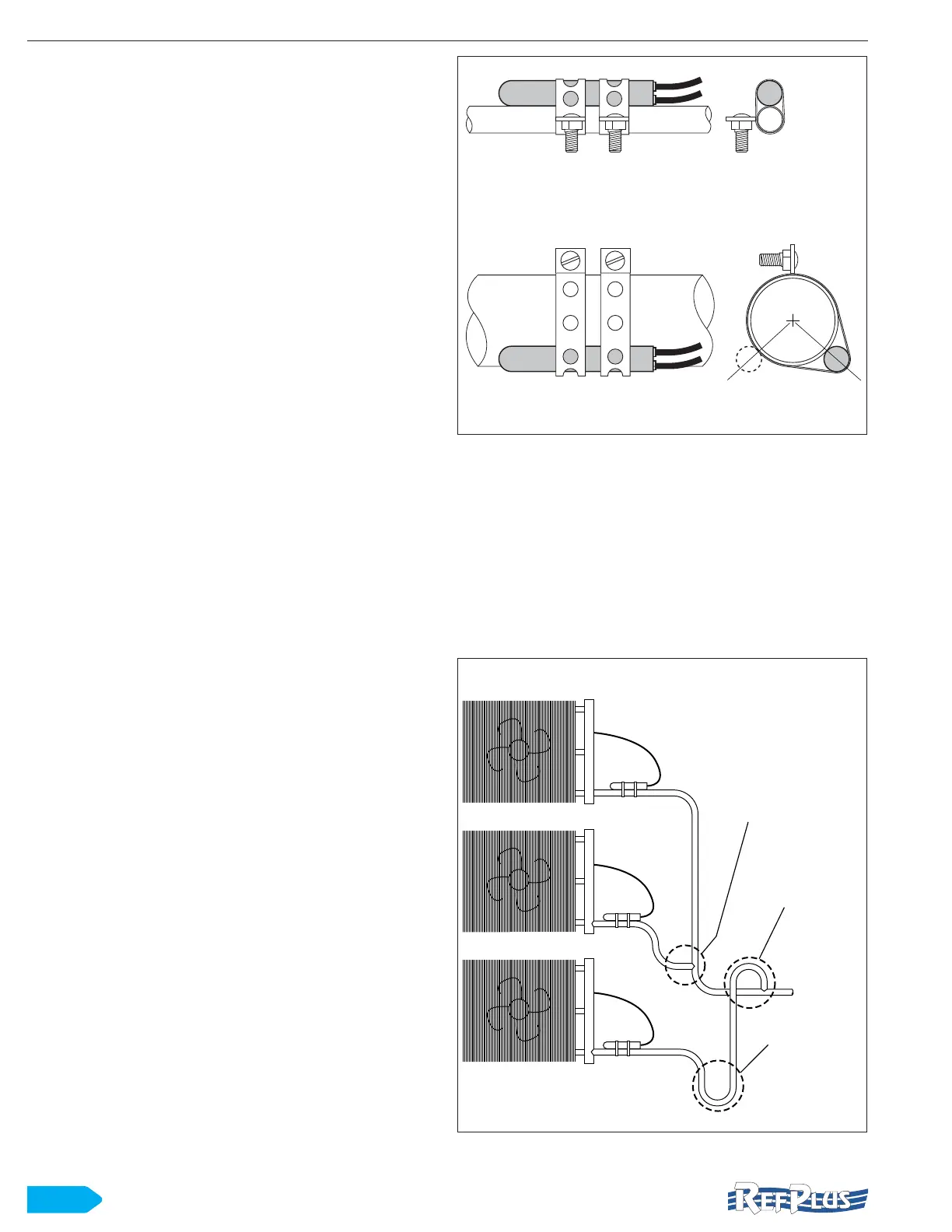

On multiple evaporator installations, the piping should

be arranged so that the ow from any valve cannot affect

the bulb of another, as shown in Figure 6. Approved piping

practices including the proper use of traps ensures individual

control for each valve without the inuence of refrigerant and

oil ow from other evaporators.

The vertical riser extending to the height of the evaporator

prevents refrigerant from draining by gravity into the

compressor during the off-cycle.

ABOVE AND BELOW MAIN SUCTION LINE

FLOW FROM UPPER VALVE

CANNOT AFFECT BULB

OF ANOTHER

INVERTED TRAP TO

AVOID OIL DRAINING

INTO IDLE

EVAPORATOR

FREE DRAINING

Figure 6 Bulb installation on multiple evaporator conguration

INSTALLATION

Loading...

Loading...