17

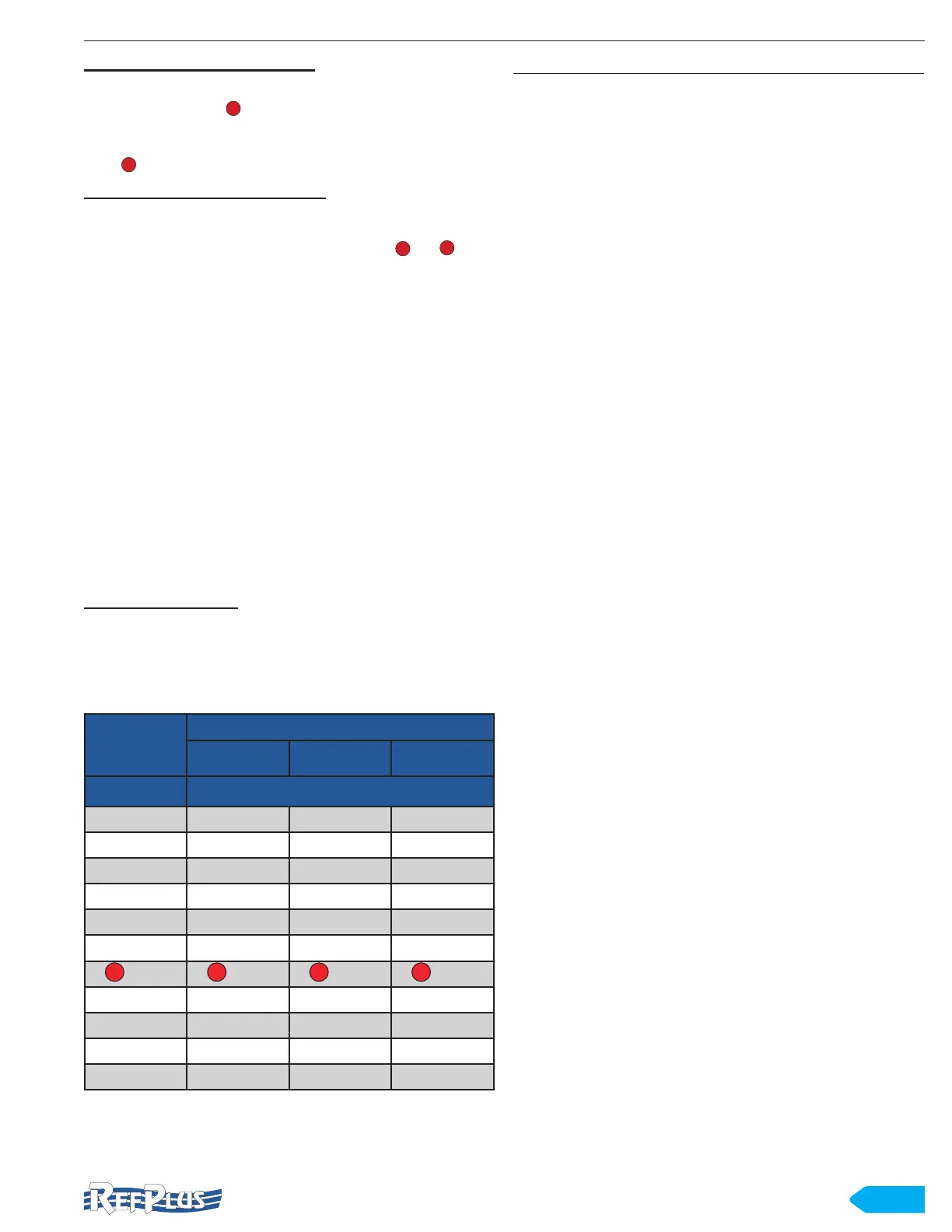

Setting Evaporator Pressure:

As an example, let say we want to achieve an average coil

temperature of 20

o

F ( in Table 3). Using a temperature-

pressure chart as reference such as the example in Table

3, now that we can begin by setting the Pressure to 51 psig

(item

).

Setting Evaporator Superheat:

In order to set the superheat, nd the Dew Point temperature

corresponding to the coil pressure. The evaporator coil

pressure and dew temperature are shown by and in the

chart below. To get superheat, compare the dew temperature

from the chart to the actual temperature of the evaporator

outlet piping. The difference in these two temperatures is

the superheat. In this example, when the pressure is 51

psig and the pipe temperature is 30 degrees, the superheat

will be 30 minus 25, or 5 degrees. As you continue to take

temperature readings, you can adjust the superheat and

pressure as needed until you’ve achieved the desired coil

temperature.

Note: In the absence of specic manufacturer recommendations,

a 4 to 6° F superheat for low temperature and 6 to 8° F for

medium temperature is recommended.

Note: When setting superheat in a system using a refrigerant

with glide, remember that pressure is constant throughout

the evaporator while the temperature will change during

boiling in the evaporator.

Adjusting for Glide:

When adjusting pressure and superheat, your goals are to

achieve the desired temperature, maximize coil efciency,

and protect the compressor for long service life. It all starts

by looking at the Pressure-Temperature (PT) chart included

with your refrigerant or any up-to-date refrigerants PT Chart.

PRESSURE

TEMPERATURE

AVERAGE BUBBLE DEW

(PSIG)

O

F

45 15 10 20

46 16 11 21

47 17 12 22

48 18 12 23

49 18 13 24

50 19 14 24

1

51

4

20

3

15

2

25

52 21 16 26

53 22 16 27

54 22 17 28

55 23 18 28

Table 3 Example of pressure-temperature chart

8. DEFROST SYSTEM

8.1 AIR DEFROST UNITS

Fan motors run continuously and a defrost time clock, or

low-pressure setting, stops the compressor when defrost is

required.

NOTE: The unit must not be in operation more than 16

hours per day.

8.2 ELECTRIC DEFROST UNITS

A time clock starts the defrost process by stopping the fan

and energizing the heaters. When the defrost thermostat

resets the time clock, it de-energizes the heaters and re-

starts the fan motors.

8.3 REVERSE-CYCLE HOT-GAS DEFROST UNITS

Reverse-cycle defrost systems introduce compressor

discharge gas through the suction line during defrost. The

amount of gas introduced is controlled by a solenoid bypass

valve and a gas defrost time clock.

Condensed refrigerant is relieved through a check valve.

The check valve bypasses the expansion valve leading to

the liquid line which has reduced pressure. The drain pan is

warmed by the entering hot gas to avoid freezing. Defrost is

initiated and terminated by the time clock.

NOTE: A minimum of 4 evaporators is required for an

efcient operation.

NOTE: The use of a suction to liquid heat exchanger is

recommended.

8.4 THREE-PIPE HOT-GAS DEFROST UNITS

During defrost, compressor discharge gas is introduced in

a separate hot gas line. The amount of gas introduced is

controlled by a solenoid bypass valve and a gas defrost time

clock.

To avoid excessive accumulation of liquid in the suction

accumulator, a heat exchanger is recommended. The drain

pan is warmed by the entering hot gas to avoid freezing. The

time clock cycles fan motors, liquid and hot gas solenoids.

NOTE: A minimum of 3 evaporators is required for an

efcient operation. Special engineering is required

for a 1 or 2 evaporator conguration. Please

contact RefPlus' Sales-Engineering department for

proper selection.

NOTE: A eld-installed pressure regulating valve may

be required on low temperature systems to control

compressor crankcase pressure.

4

1

1

2

DEFROST SYSTEM

Loading...

Loading...