13

6.8 SUCTION LINE CONSTRUCTION

RECOMMENDED VELOCITY FOR GOOD OIL RETURN OF POE WITH HFC - FPM (M/S)

FPM

Minimum

Horizontal

Minimum

Vertical

Design Maximum

Condensate NA NA ≤ 100 (0.5) 150 (0.8)

Liquid NA NA ≤ 300 (1.5) 300 (1.5)

Suction 500 (2.5) 900 (4.6) 1000 (5.1) - 3000 (15.2) 4000 (20.3)

Discharge 500 (2.5) 900 (4.6) 2000 (10.2) - 3000 (15.2) 3500 (17.8)

HG Defrost 500 (2.5) 900 (4.6) 1000 (5.1) - 2000 (10.2) 3000 (15.2)

Table 2 Recommended velocity for good oil return of POE with HFC - FPM (m/s)

INSTALLATION

IMPORTANT: A calibrated pressure gauge and regulator

must always be used with nitrogen cylinders.

The suction line must be sized to maintain proper line

velocities with a practical line pressure drop. It is usually

equal to 2°F (1.1°C). To ensure proper oil return, all horizontal

lines must be sloped down toward the compressor with a

minimum pitch of 1/4” (6.4 mm) per 10 ft (3 m).

An access tting must be installed (when not part of the

evaporator) on the evaporator suction line to read an

accurate suction pressure for superheat adjustment.

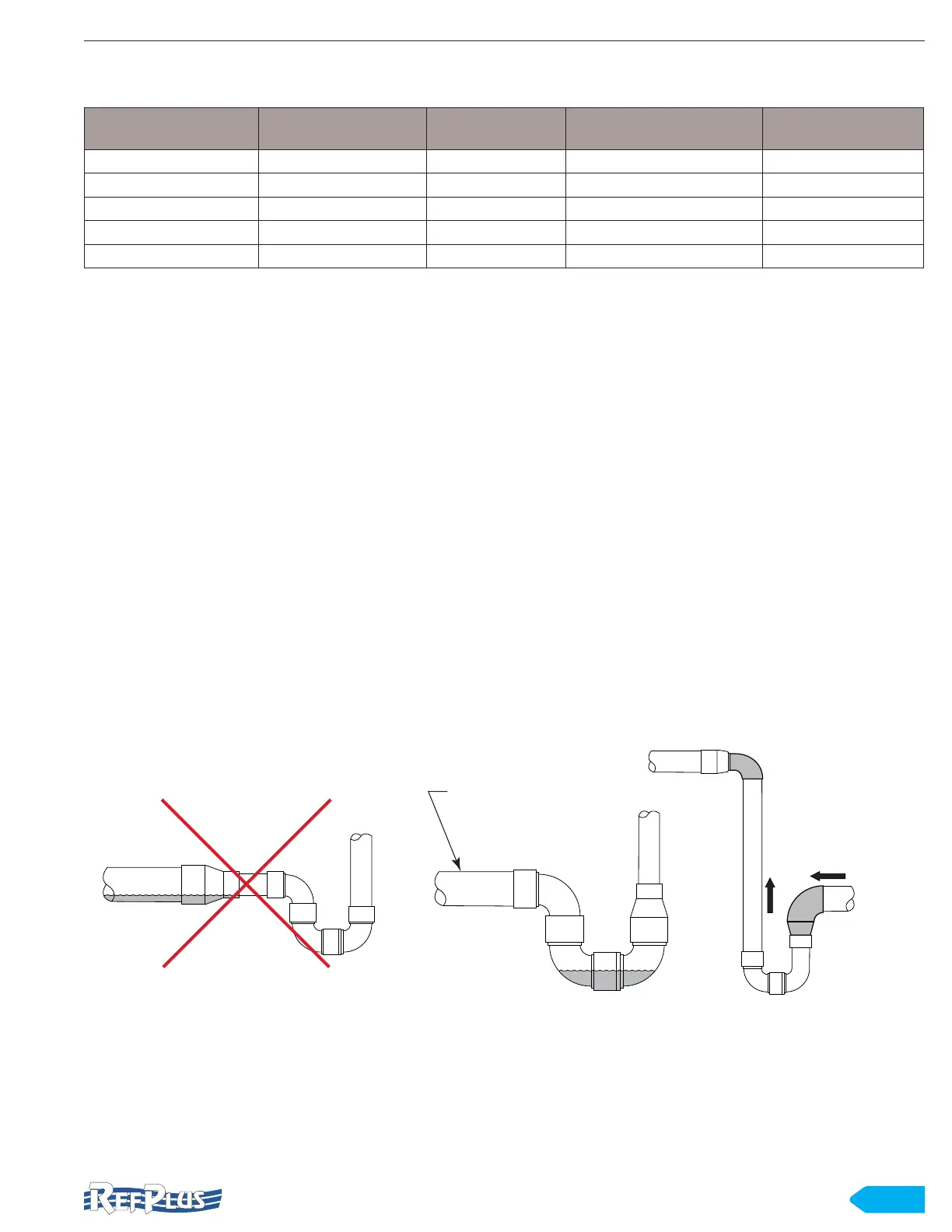

In situations where it is necessary for the suction line to rise,

an oil trap must be installed at the bottom of the riser as

shown in Figure 7, page 13. To ensure oil return through a

riser in the suction line, a velocity of no less than 1000 FPM

(5.1 m/s) is required. When a system has capacity variation

or unloaders, a double riser when at less than 50% capacity

may be necessary to keep the velocity at a minimum of 900

FPM (4.6 m/s). You can drop one size for suction riser to lift

the oil. A trap should be provided for each additional 20 ft

(6 m) of riser. See Figure 8.

Avoid oil and refrigerant migration between active and

inactive evaporators in a common suction system. When

multiple evaporators are connected to a common suction

line, it must enter from the top. The rst evaporator suction

connection should have an inverted trap as shown in Figure

9.

Suction lines should not be exposed to heat or the sun.

The line must be properly insulated if it is necessary to run

suction line outside of the building or through heated areas.

The suction line must be insulated in any situation where the

pipe may sweat or freeze.

If isolation valves are installed on the suction lines, full port

ball valves should be used.

OIL

OIL

SLOPE 1/4”

PER 10 FT.

TOWARD

COMPRESSOR

IMPROPER

PROPER PROPER

INSTALL REDUCERS

IN VERTICAL PIPE

INSTALL EXPANDER

IN HORIZONTAL PIPE

Figure 7 Suction oil trap construction

Loading...

Loading...