19A-63

COOLING

Plenum chamber: Removal - Refitting

K4M

19A

-the coolant outlet unit,

-the coolant outlet unit seal.

REFITTING

I - REFITTING PREPARATION OPERATION

a parts always to be replaced: Cylinder head coo-

lant outlet unit seal (10,06,01,19).

a Use SURFACE CLEANER (see Vehicle: Parts

and ingredients for the repairwork) (04B, Consu-

mables - Products) to clean and degrease:

-the cylinder head joint face,

-the coolant outlet unit housing if it is being reused.

II - REFITTING OPERATION FOR PART

CONCERNED

a Refit the coolant outlet unit with a new seal.

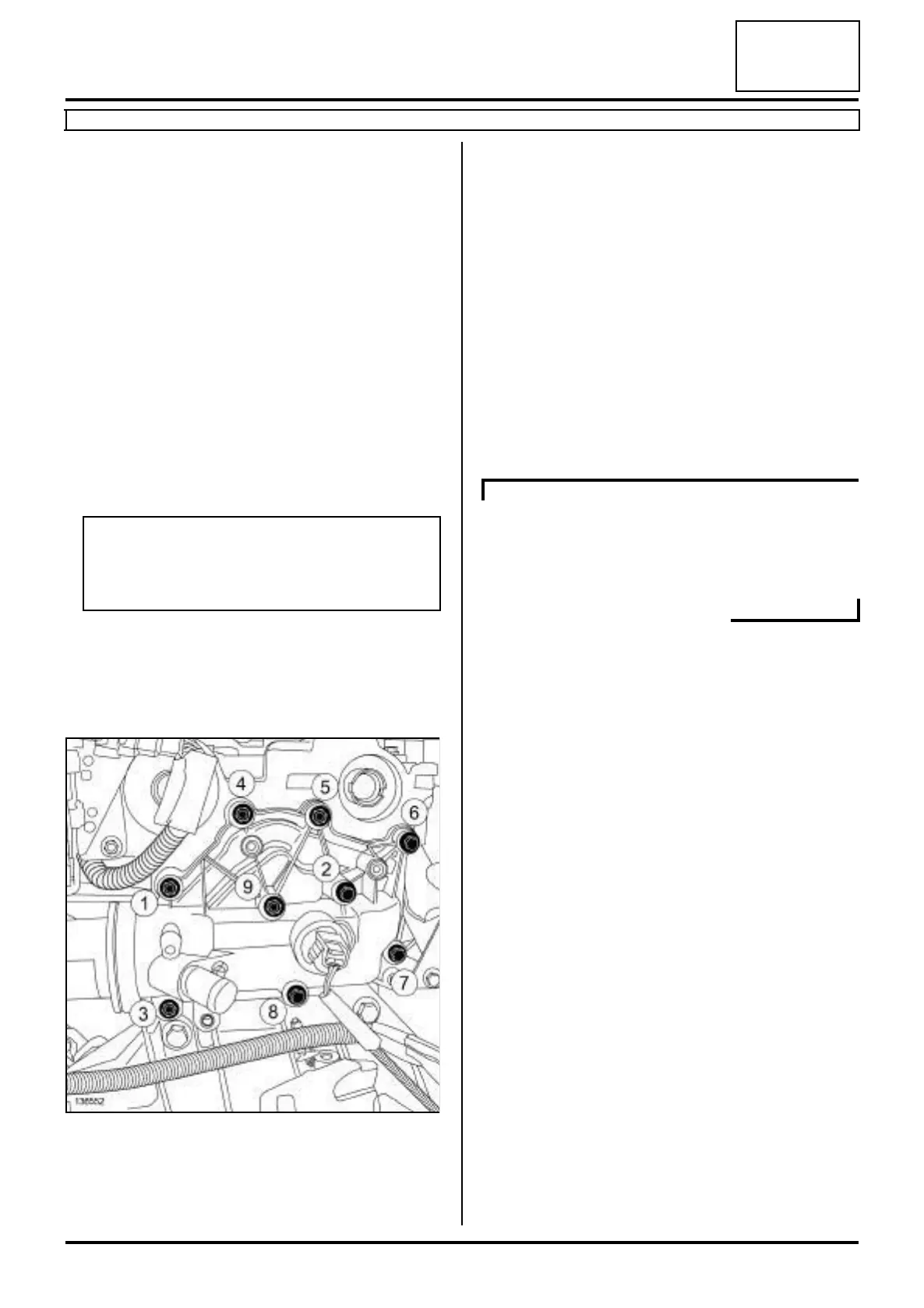

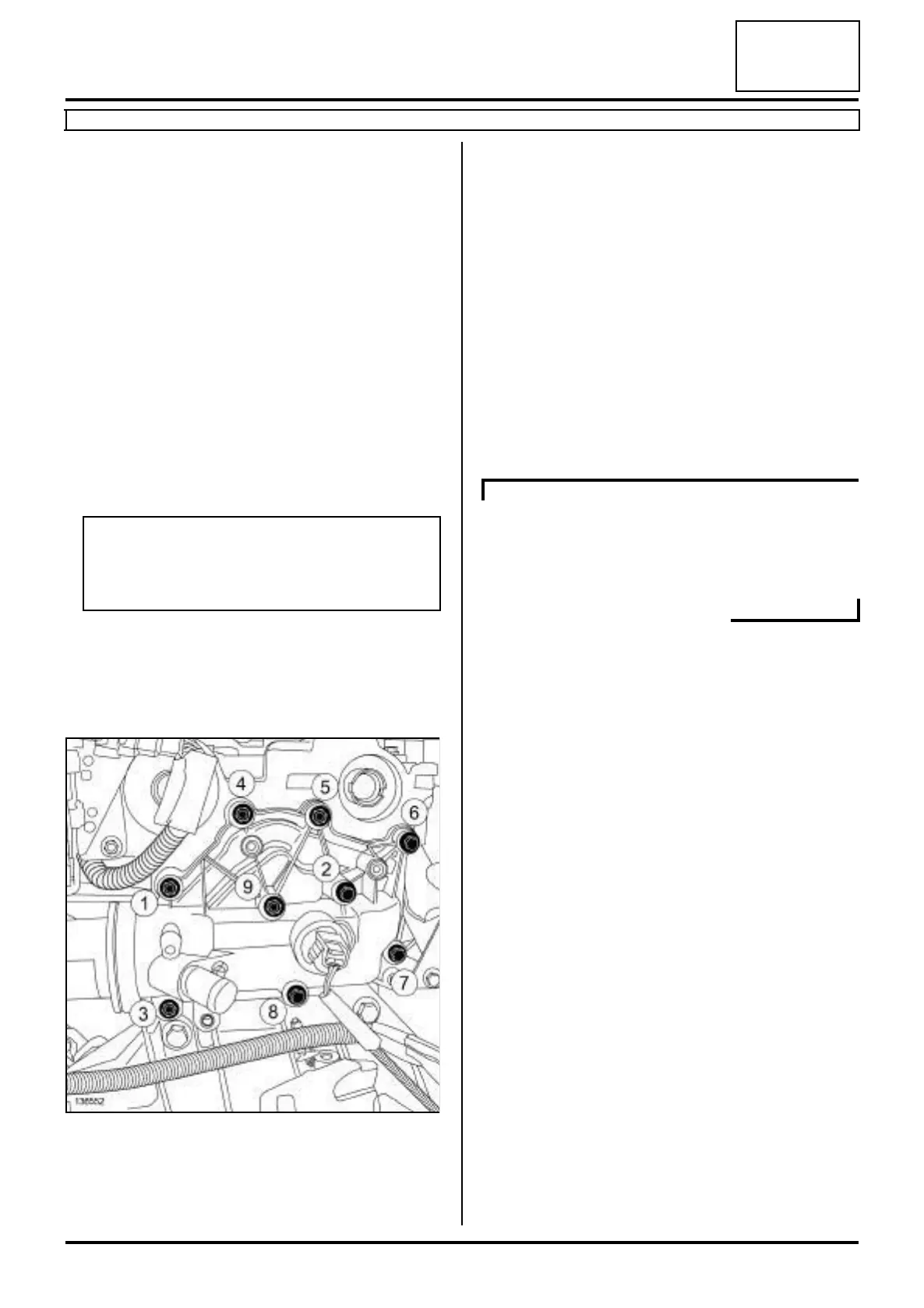

a In order, fit (without tightening):

-the coolant outlet unit bolts (1) and (6) ,

-the bolts (2) , (3) , (4) , (5) , (7) , (8) , (9) .

a Tighten to torque and in order:

- the coolant outlet unit bolts (initial torque) (4

N.m),

- the coolant outlet unit bolts (12 N.m).

a Refit the heater matrix hose bracket on the retaining

bracket.

a Torque tighten the heater matrix hose retaining

bracket (10 N.m).

a Clip the heater matrix hoses onto the retaining brac-

ket.

III - FINAL OPERATION

a Refit the engine wiring channel.

a Connect the TDC sensor connector.

a Refit the coolant temperature sensor (see 19A,

Cooling, Coolant temperature sensor: Removal -

Refitting, page 19A-101) .

a Connect:

- the top hose on the coolant outlet unit,

- the heater matrix hose.

a Using the (Mot. 1448), fit:

- the heater matrix hose clip,

- the cooling radiator top hose clip.

a Refit:

- the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

- the engine undertray,

- the front section of the front wheel arch liners (see

Front wheel arch liner: Removal - Refitting)

(55A, Exterior protection),

- the front wheels (see Vehicle: Towing and lifting)

(35A, Wheels and tyres),

- the engine cover.

a Fill and bleed the cooling system (see 19A, Coo-

ling, Cooling circuit: Draining - Refilling, page

19A-17) .

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger marks).

136552

K4M, and 848

Loading...

Loading...