41

XL laser system

XL-80 hardware XL-80 applications

Diagnostics and troubleshooting

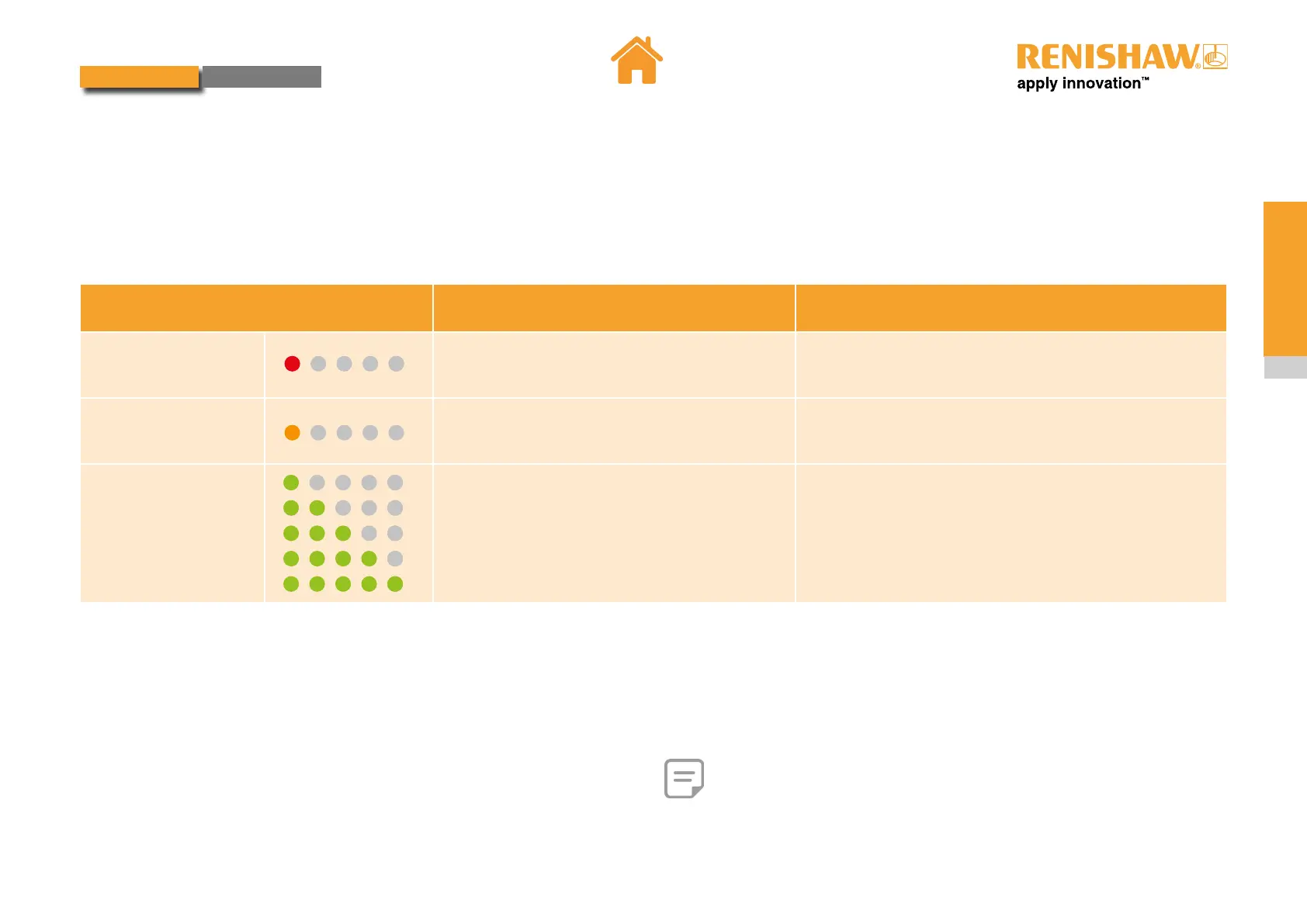

Signal strength LED status

LED status Description Actions

Solid red Beam break - measurements cannot be made,

• Check laser beam is present

• If no laser beam, power cycle

• If issue persists, contact local Renishaw office

Solid amber

Beam low - measurement accuracy is reduced,

danger of beam break occuring

• Check laser alignment

• If measuring separation > 40 m use high gain mode

• If issue persists, contact local Renishaw office

Single green LED

indicates minimum

beam strength,

increasing up to 5 green

LEDs for maximum

beam strength.

Signal strength OK. Open Capture in XL mode

Beam strength LEDs

At the front of the top panel of the XL laser there are 5 LEDs. These have a dual

function:

1. Preheat mode:

When the XL laser is first switched on and is undergoing preheat, the

beam strength LEDs will initially all turn amber. As the preheat sequence

progresses, the LEDs will go out in turn, indicating how far through the

sequence the laser has progressed. When the final amber LED goes out

the LEDs will then switch to ‘beam strength’ mode.

2. Beam strength mode:

When the laser is switched on and has stabilised, the 5 LEDs indicate the

returned beam strength i.e. the level of interference between reference and

measurement laser beams returned from the external optics. This provides an

indication of how well the laser and optics are aligned, as shown in the table

above. These LEDs are in addition to the beam strength indication in system

software, but are helpful when working away from the computer screen.

Note: When there is sufficient signal strength to maintain a single green

LED, the system accuracy is independent of signal strength.

Loading...

Loading...