23

eRev. [Major Version]1.01.0 8/9/2023

KrosFlo® KR2i Real-Time Process Management (RPM™) System

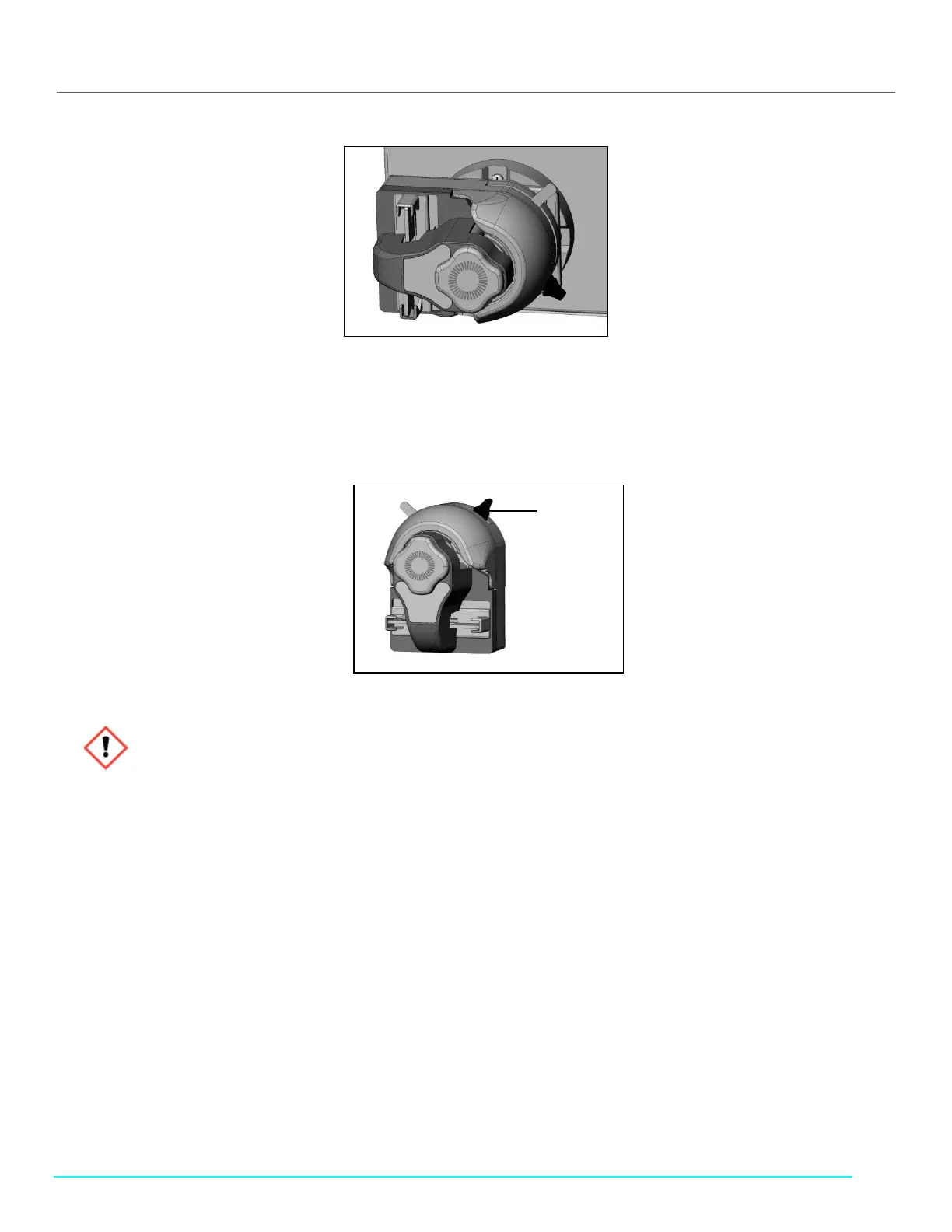

Figure 10. Bayonet feature locked in horizontal pump orientation

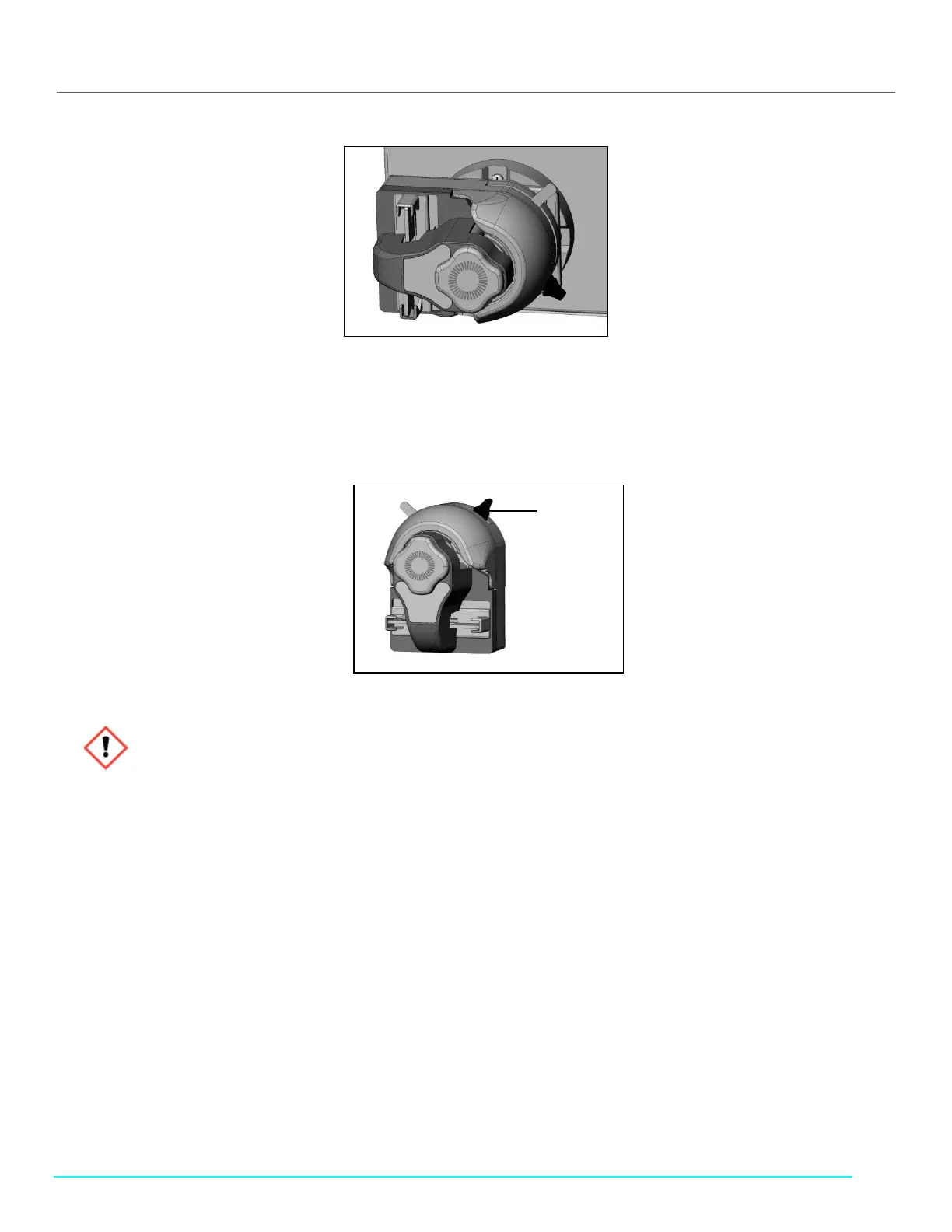

3. Remove the pump head from the drive by holding the bayonet lock lever forward while rotating the pump head as far as

possible in the counterclockwise direction, then pull the pump head away from the drive to detach it. The actuator lever

should be in the far right position when removing the pump head (see Figure 11).

Figure 11. Pump head in fully closed position

8.4 KR2i Tubing

1. To load tubing, open the pump head by moving the actuator lever counterclockwise (see Figures 11 and 12). Insert a loop of

tubing into one open tubing retainer, between the occlusion bed and the rollers and into the other tubing retainer (see

Figure 13). Position the tubing so that it is firmly centered against the rollers. While holding the tubing ends, move the

actuator lever back to the far clockwise (right) position, as shown in Figure 11. The pump head will automatically grip the

tubing. Approximately 5 pounds of force must be applied to the actuator lever to fully close the pump head and place the

lever in its locked position (far right position) or to fully open the pump head (far left position).

Note: It is unnecessary to have an end of the tubing free to load or unload tubing from the pump head. A length of tubing

may be loaded into the pump without disconnecting it from adjacent devices.

Actuator

Lever-Far

Right Position

Bayonet Lock

Lever-Pull Forward

to Release

WARNING: Stop the pump drive before installing or removing tubing from the pump head.

Loading...

Loading...