6.5 Inserting the Grinding Container

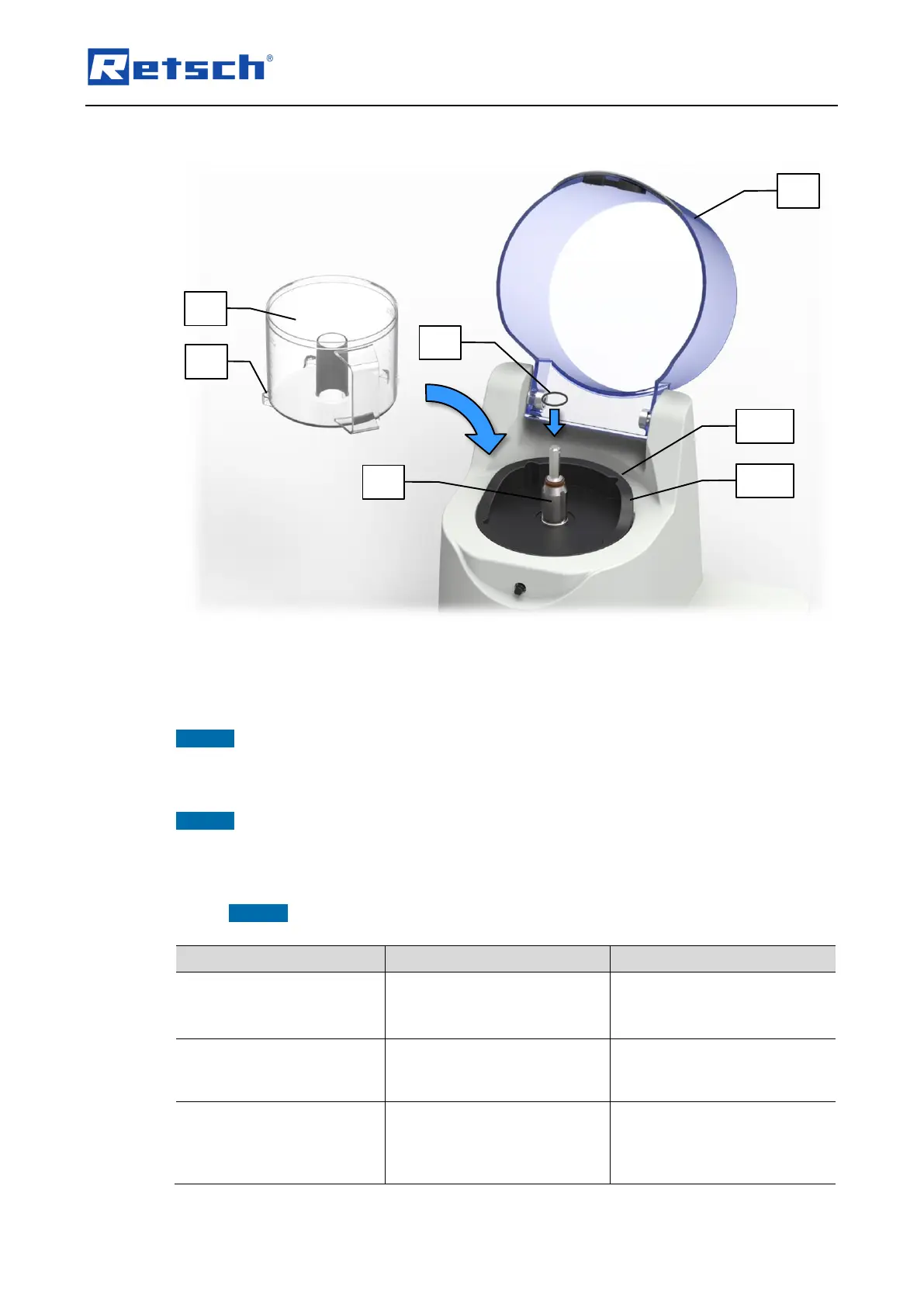

Fig. 4: Inserting the grinding container

Open the hood (F).

Insert the grinding container (MB).

NOTICE Depending on the design, the grinding container has one to three anti-rotation locks

(MB1) which fit into the grooves (MBA1) of the grinding container receptacle (MBA). On

insertion, pay attention to the correct orientation of the grinding container.

NOTICE An O-ring (OR) serves as a seal and fixation for the grinding container receptacle

(MBA). When inserting the grinding container, ensure the correct seating of the O-ring in the

groove of the motor shaft (MW).

Grinding containers made of different materials are available for the GM 200 from Retsch

GmbH. NOTICE Not all grinding containers are suitable for the grinding of all sample materials!

Please note the following table when selecting the grinding container:

Type of grinding container

soft, medium hard, elastic,

aqueous, greasy and oily

sample material

hard, hard-brittle sample

material due to increased

abrasion

soft, medium hard, elastic,

aqueous, greasy and oily

sample material

hard, hard-brittle sample

material due to risk of fracture

Stainless steel container

soft, medium hard, elastic,

aqueous, greasy, oily, hard

and hard-brittle sample

material

Loading...

Loading...