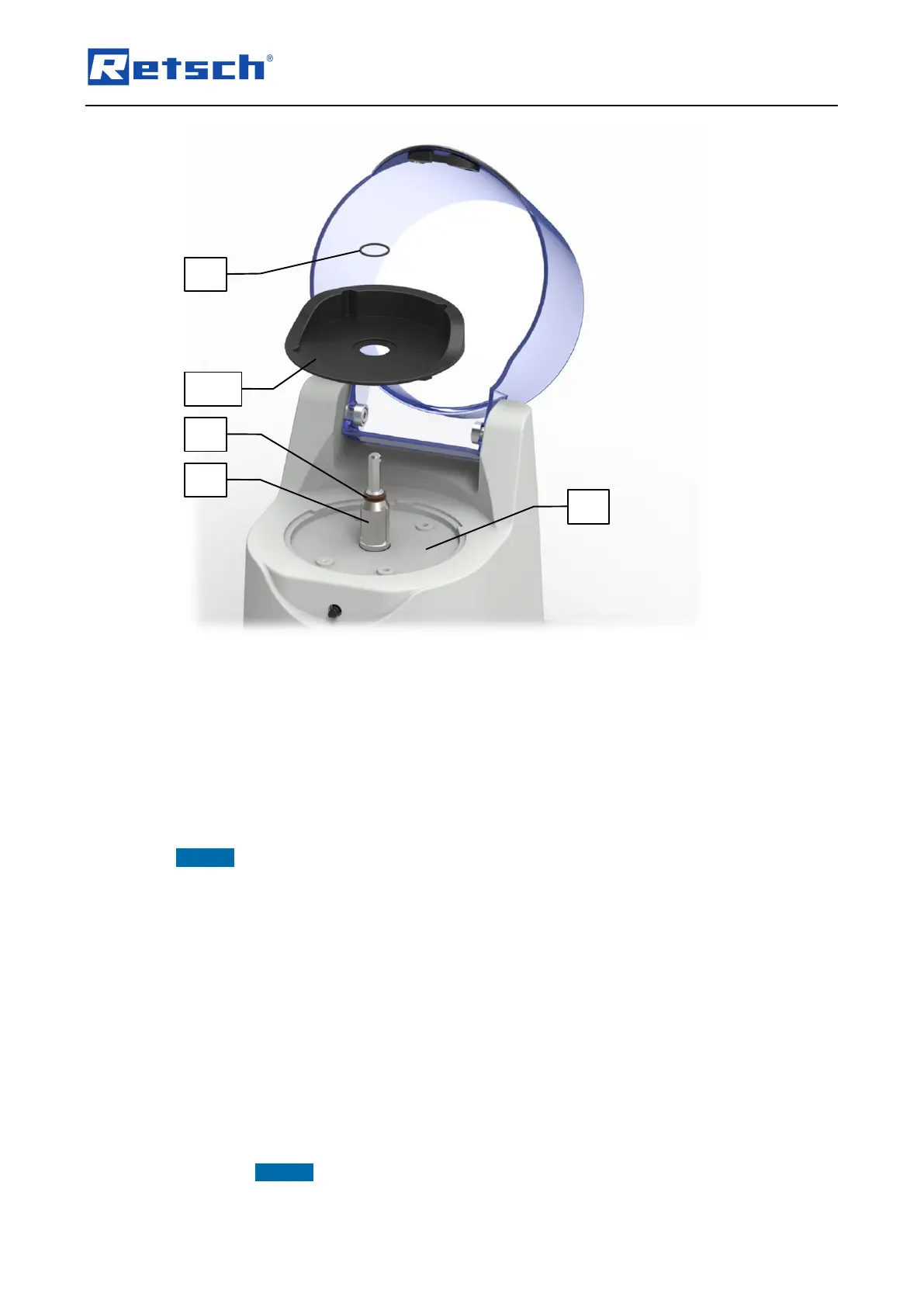

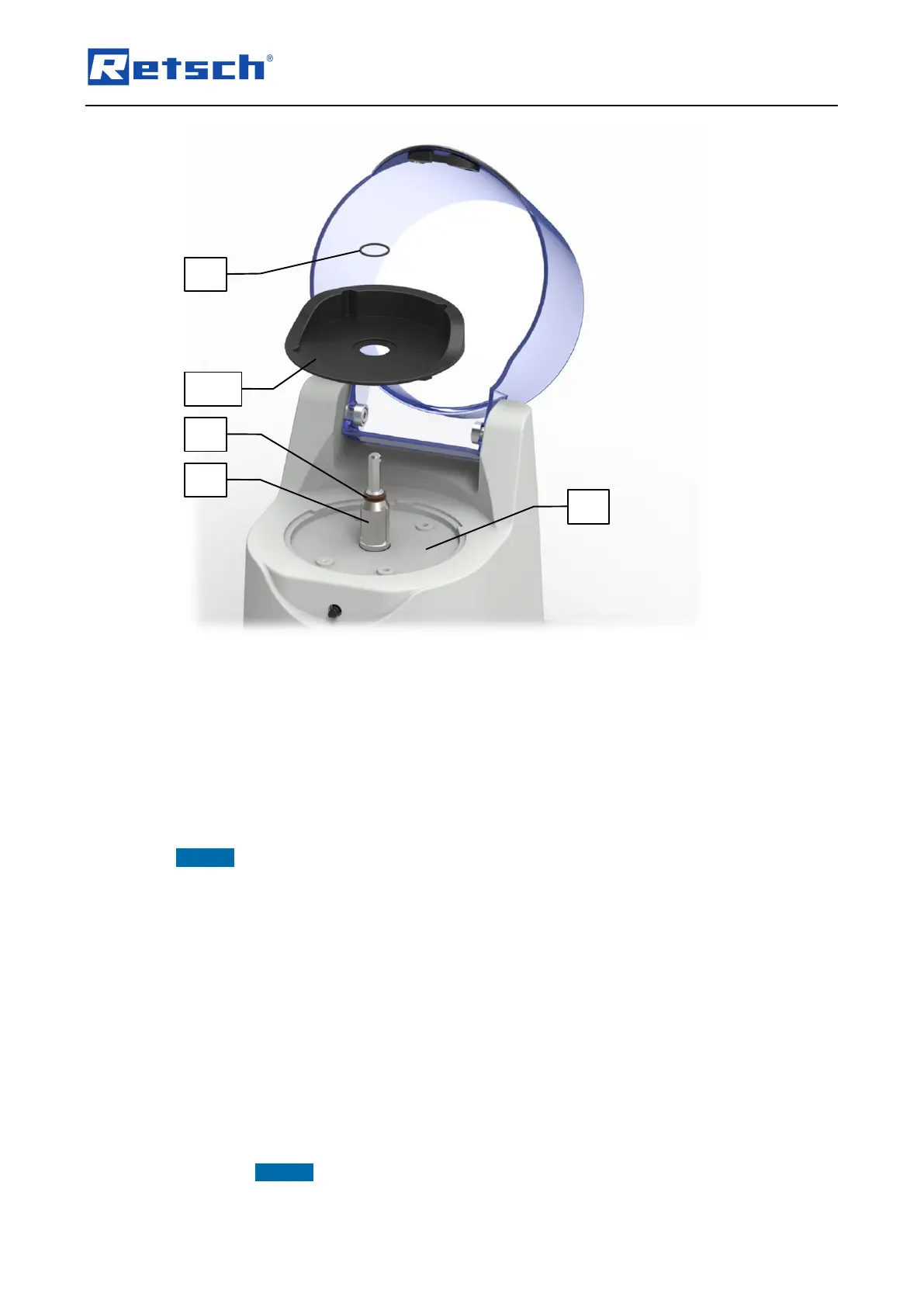

In case of frequent and heavy contamination of the grinding container receptacle (MBA) with

liquid or greasy samples, sample material can get under the grinding container receptacle.

Remove the O-ring (OR), which seals the grinding container receptacle.

Remove the grinding container receptacle (MBA) and clean its underside.

Clean the area (BO) underneath the grinding container receptacle.

When re-installing the grinding container receptacle, ensure that the O-ring (OR) is correctly

seated in the groove on the motor shaft (MW).

NOTICE Check the degree of contamination at regular intervals. Sample material can otherwise

enter the interior of the device under unfavourable circumstances.

9.1.1 Cleaning the Grinding Set

The cleaning of the grinding set consisting of grinding container, lid and knife insert should be

carried out regularly. All parts can be cleaned with alcohol, petrol or normal household

detergent. In addition, all parts are dishwasher suitable.

Except for the plastic grinding container made of PP (polypropylene), all parts are also

autoclavable.

9.2 Wear

The grinding sets may become worn, depending on the frequency of the grinding operation and

the sample material. The grinding sets should be regularly checked for wear and replaced if

necessary. NOTICE Never use plastic containers, which have stress cracking! Those must be

replaced immediately!

Loading...

Loading...